Paul Dvorak / Editor

At wind farms today, most condition monitoring involves turbines sending data about operating conditions to a home base, where the wind-farm operator reviews it and makes decisions. At the wind site, the controls in each turbine look for conditions that might damage the unit, such as violent wind gusts, and then shut the turbine down.

Most restarts call for human intervention at the site, a time-consuming task. But what if the turbine controls, with input

In a Node-RED demo, developer Nick O’Leary drags device modules from the stack on the left and drops them into the work area. The connecting lines imply the network connections. The output of the software is the control instructions that would be loaded, for our purposes, onto a turbine control.

from surrounding turbines and a forecast, could make that decision themselves and restart the turbine?

This concept is made possible by the Internet of Things (IoT), which is morphing into the Industrial IoT (IIoT) and demonstrating intelligence and capabilities that will make the wind industry’s investments more profitable.

IIoT today

At first, the IIoT sounds like a network. But it is more, explains Craig VanWagner, Research & Development Engineer with Scada Solutions, Inc. The company specializes in design engineering and data acquisition systems. The IIoT, he says, takes a big step beyond condition monitoring and lets machines swap actionable information, such as wind forecasts and power demand. That means the machines can make decisions when a human wind farm operator is not available.

“It’s quite a bit more than an advanced network,” adds Matt Newton, Director of Technical Marketing at Opto 22. “More goes into it from a software perspective and in terms of communications capabilities, new data sets, and analytics. It goes well beyond just physical devices transmitting electrical signals.”

But how can actionable data be produced and communicated? Are you going to install a Linux system in a new device and run that OS along with a lot of support software?

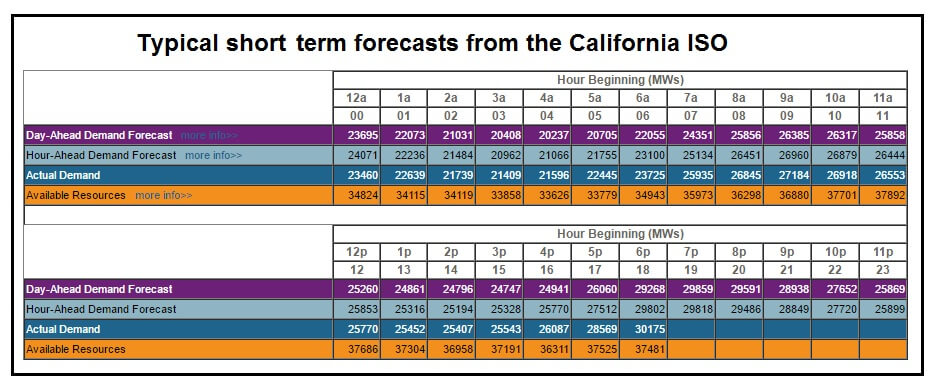

California ISO makes information of this sort digitally available online. It can become the input for IIoT turbine controls, signaling shut downs when power prices go too low.

“Previously, a developer would have to use a database or OTC server to get multiple machines communicating. There had to be code in the system that somebody programmed to speak different protocols,” says VanWagner. “A better idea is to develop something quick and light to communicate out.”

Thanks to the IIoT, that is now possible. “With the IIoT there is now a software module that makes it easy to share data,” says VanWagner. “I think we will see a lot more things coming out of this IIoT.”

Opto 22 has developed a line of industrial controllers, I/O modules, and systems that work with Internet applications through a RESTful API, and also serve as the industrial control logic.

CMS tomorrow

This step in the evolution of condition monitoring is just getting underway. At present, there are few components and protocols that let devices and systems swap useful information. However, several companies and organizations are working to tackle that problem through the invention of new technologies. One of those technologies, called Node-RED, (nodered.org) was originally created by software developers at IBM and is now part of the JS Foundation, a Linux Foundation Project. Node-RED is described as a visual software tool for wiring together hardware devices, APIs (application program interfaces), and online services in new and interesting ways.

In an online demo, Node-RED developer Nick O’Leary says the IIoT is about accessing information and letting the intelligence in the equipment do something with it. This idea is called actionable intelligence. O’Leary says Node-RED consists of small, pre-built programs called nodes, used in the Node-RED development environment. “Software tools integrate right into the development environment for controls, which allows you to wire together all kinds of information sources and actions, and to do neat stuff without writing a lot of code.”

So instead of developers taking the time to figure out or remember how to access a simple serial port through their software development tools, Node-RED provides prebuilt, reusable code blocks to do that. Developers can focus on creating something new with real value instead of doing repetitive software development tasks. In a demo, O’Leary drags device protocols from a list, drops them onto a workspace, and connects them with lines. The devices include inputs, instructions as to what should happen to the data from the inputs, and where the data should go—that is, the outputs. A similar graphic user interface and design technique have been used before to assemble wiring diagrams and fluid power systems.

“The industry needs tools that make it easier for developers at all levels to bring together different streams of events, physical and digital, that make up the IIoT,” says O’Leary.

Another plus: If a manufacturer can make a device along with a Node-RED module, then it becomes available to anyone who needs data from the device. “Now people can, for example, poll a device or send data to a device with instruction software written by simple drags and drops. As development tools like Node-RED become more widespread, wind farms will get smarter and more profitable,” adds VanWagner.

As usual, the IIoT concept is simple, while making logical connections is complex. “As people build more devices, they are incorporating a greater ability for the devices to talk to others on the Internet or a network,” says VanWagner. “The IIoT has protocols available to make it easier for developers to connect devices.” What’s more, manufacturers and network connectivity devices are getting smaller and less expensive, so it is possible to put network connectivity into more devices.

The big apps

A big application for the wind industry is in predictive maintenance, figuring out when something is going to break before it breaks.

“Then it would be possible to know the right parts to service the equipment and have them on hand the first time a technician visits the site. IIoT proliferation will accelerate now that we are past the initial introduction point and people are beginning to see the possibilities,” says Newton.

VanWagner adds another example. An application in Southern California monitors the market price for electrical power. If the price goes up, a wind-farm operator may put more generation online. Just as important, if the power price drops or goes negative, through the IIoT the turbine can interrogate a website for the market price, autonomously make a decision, and send a control signal to its components to shut down. Negative pricing means the wind-farm operator pays the utility to take the power. “During the Christmas period 2015, the price dropped to negative $250/GWh for hours,” says VanWagner. “Had a wind-park operator left the site running, he would have had to write a $30,000 check to the utility. That is what he would have lost for the week.”

That is a big deal because the industry is not ordering curtailments as often as before. Instead, organizations responsible for power, such as CAISO (California Independent System Operator), are relying on negative pricing to control production. “So if an operator can get real-time information on pricing, and the price goes below a reasonable profit threshold or negative, then the operator can make better decisions,” says VanWagner. He also predicts that a significant number of companies will be showing IIoT connectivity at the upcoming American Wind Energy Association (AWEA) Windpower show.

Filed Under: Uncategorized