Written by Craig Walker

Contributor

The demand for large, utility-scale energy storage systems is expected to increase with the development of renewable energy projects. The variability of renewables poses added challenges to electric grid operators, who must balance the grid reliably. Energy storage is one way to store excess power for later use or emergency backup.

“Wind and solar power have high ramping rates and this creates a need to make up that demand,” explains Dr. Robert

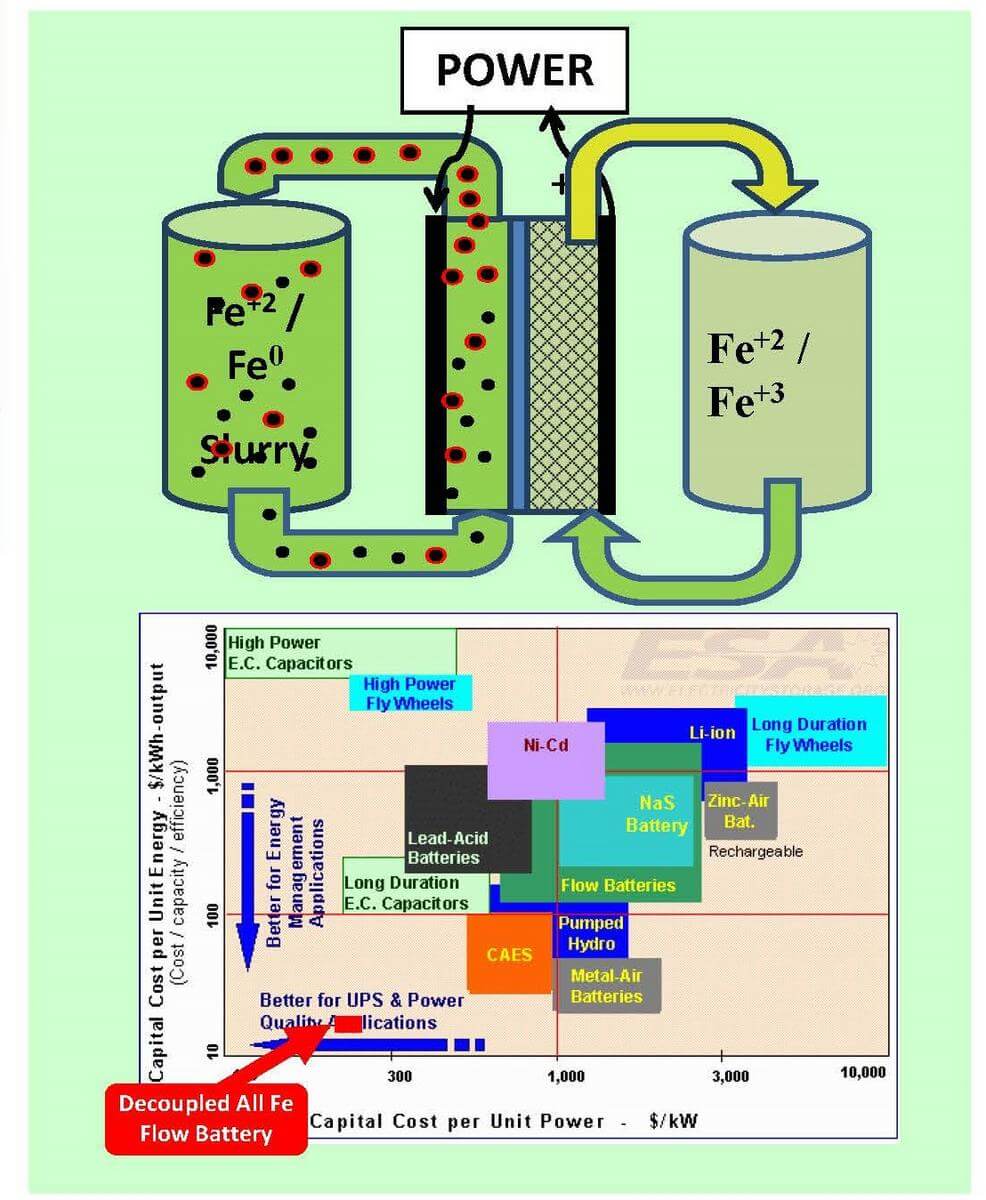

On top: A depiction of the iron flow from the two separate tanks, which are filled with electrolytes, and into a third chamber where the chemical reaction takes place. On bottom: A graph comparing the energy storage costs of competing technologies.

Savinell, Professor of chemical engineering, who is heading up ongoing battery research at Case Western Reserve University (CWRU) in Ohio. Ramping is the ability of a power-generating facility to start and stop on command, which is important for operators who must balance the grid by offsetting the rapid output variability of wind and solar.

Savinell and his team at CWRU are working on a prototype decoupled iron-flow battery to store power generated from grid-scale wind and solar facilities in a scalable and cost-efficient manner. “When renewable energy reaches approximately 15 to 20% of total power generation, utility-scale storage is required,” says Savinell.

An all-vanadium flow battery is one option for such large-scale projects, however vanadium is costly. So CWRU’s research team is working on an alternative: a water-based iron system.

“Flow batteries store chemical energy in external tanks instead of within the battery container. Using iron provides a low-cost, safe solution for energy storage because iron is both abundant and non-toxic,” explains the U.S. Department of Energy’s (DOE) Advanced Research Projects Agency-Energy (ARPA-E) project site.

“The DOE initially funded the exploratory stage at CWRU a number of years ago and then ARPA-E continued funding thereafter to push the concept through to commercialization,” he says.

According to the ARPA-E, a flow battery cell generates power by pumping the electrolyte through a membrane stack, which serves as the facilitator of energy transfer. The duration of power generation has been found to increase with the amount of available electrolyte — or the size of the electrolyte storage tank.

The researchers at CWRU are storing the reactants used to produce electrical energy in two separate tanks that then enter another chamber, where the chemical reactions take place. The reactants are pumped in one direction through the chamber to charge the battery, and the other direction to discharge the system. By separating this process into three components and in different sized tanks enables the battery to be scaled effectively.

“Right now, we are looking at a storage cost of about $30 to $50 per kilowatt-hour,” says Savinell. “Bringing down the costs of renewable energy generation and storage is something that can only help the entire renewable energy industry.”

Energy Storage Systems, a long-duration energy storage system provider based in Oregon, has been manufacturing the electrodes for the project. CWRU also recently partnered with an Australian firm to bring iron-flow batteries to market.

The all-iron flow cell chemistry under development is low cost, non-flammable, and non-toxic. “This combination makes it suitable across a variety of application scales, ranging from distributed energy storage in commercial and industrial buildings to very large, commodity grid-scale storage,” says the ARPA-E.

To read more about this project, click here.

Filed Under: Energy storage, News