The largest wind turbines have a capacity of 5 to 7 MW. After five years of research at the joint European project, UpWind, led by Risø National Laboratory for Sustainable Energy and the Technical University of Denmark, presented a first design basis for developing turbines of 20 MW. The project started five years ago with more than 120 wind scientists and a budget of 23 million Euros to provide the answer to the big question: Is it possible to build a 20-MW wind turbine using the methods and materials known today?

“One conclusion from the project is that if you built a 20-MW wind turbine based on existing technologies and methods, it will be only 15 to 20% more expensive than today’s wind turbines,” said project lead Peter Hjuler Jensen. “That is far from discouraging. I would have expected that such a simple upscaling would revealed higher costs.”

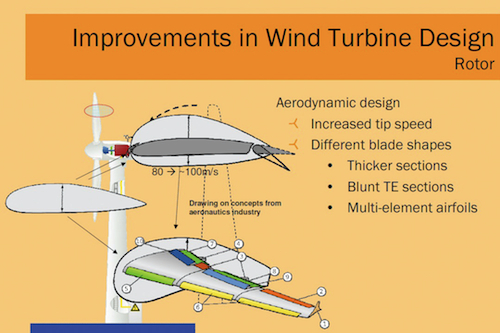

One conclusion from the Upwind project is that a smart rotor will be needed for a 20-MW turbine. Each rotor blade would have leading and trailing flaps, similar to an aircraft wing, to improve energy capture.

Risø and DTU Mechanical Engineering have developed aeroelastic design methods for wind turbines up to 20 MW. The methods calculate a wind turbine’s dynamic response to turbulence. In the UpWind project, organizations studied aeroelastic methods, materials, management and regulation, and other technologies necessary for designing a 20-MW model.

One significant contribution has been the smart rotor blade with controllable trailing edges, like the flaps on an airplane wing. The team tested various movable trailing edges for blades and different mechanisms for activating trailing edge movement, while aerodynamics of the movable edge has been studied in wind tunnels.

“We also worked on several different types of sensors such as pitot tubes, which are also used to measure the wind speed of aircrafts,” says Jensen.

“Introducing these innovations to existing wind turbines would probably be more expensive, but if implemented on large turbines, the savings from load reductions probably would be competitive. We concluded that upscaling opens a door to new technologies.”

WPE

Filed Under: Uncategorized

i have steam turbine exp.50mw cogen plant