Fabrizio Sardella,

The MAIT Wind Division

MAIT S.p.A.

Università Politecnica delle Marche, Ancona

In Europe, MAIT is a well known manufacturer of construction equipment such as drilling machines for foundations. As a consequence of internal feasibility studies and evaluations developed in 2008 and 2009, the company decided to enter in the wind-energy business as wind-turbine manufacturer.

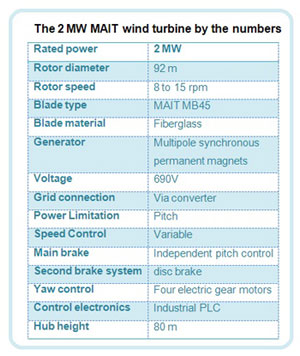

T he wind turbine under development is a 2 MW, direct-drive machine for medium-low wind speed sites (IEC Class IIA). Its main characteristics are revealed in this article. For instance, company engineers decided on these requirements

he wind turbine under development is a 2 MW, direct-drive machine for medium-low wind speed sites (IEC Class IIA). Its main characteristics are revealed in this article. For instance, company engineers decided on these requirements

- high efficiency

- comply fully with grid connection requirements

- transport easily

- maintain easily, and

- generate low noise.

With regard to the high efficiency requirement, designers selected a direct drive.

- the Direct-Drive solution allows eliminating a gearbox between the rotor and the electrical generator. Eliminating the gearbox provides an important mechanical simplification which has an impact on the general efficiency of the power plant (it improves reliability). No generator also eliminates power losses from the gearbox which means more energy available on the grid.

- the multipole, permanent-magnet generator ensures optimal efficiency especially at low wind speeds.

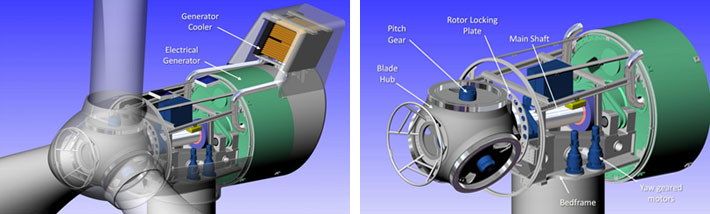

- ideal working conditions. The MAIT turbine is characterized by the position of the generator – near of the nacelle – while the most competitors place the generator between the rotor and tower. The lay-out lets the generator work in ideal conditions because all bending loads coming from the blades are absorbed before they arrive at the generator structure. In this way the gap between stator and rotor is particularly stable, improving the generator efficiency. Furthermore, the particular configuration allows forced ventilation which avoids the inlet of the external air into the generator, eliminating the external air contamination due to dust and humidity.

- tailored rotor blade – The rotor blade has been developed in co-operation with an Italian university and an international composite manufacturer, especially for the MAIT turbine

Full compliance with grid connection requirements

The adoption of a full converter allows to control the turbine respecting the requirements included in the “allegato 17” to the grid connection rules, such as the grid fault drive through and the regulation of frequency, voltage and power factor, according to the grid needs

The cut-away shows the location of the generator and its cooler (left). MAIT engineers placed the PM generator back a bit for more room to work in the nacelle and for better balance (right).

Transportability

- the overall dimensions, in particular the generator’s diameter, allow transporting the nacelle completely assembled with the exception of the generator cooler

- three blades can be transported on the same truck, where allowed by local regulations, due to the absence of the pre-bending on the blade shape

Easy maintenance

- the MAIT turbine is completely controlled by electrical devices and actuators. It uses no hydraulics.

- in case of important failures it is possible to swap the complete generator without dismounting the blades, as is often the case with the conventional configuration – the generator between the rotor and the tower

- the nacelle and hub allow the easy substitution of the electro-mechanical actuators without need of external cranes

Prototype certification

The prototype certification includes a design assessment and prototype testing.

The design assessment has been committed by MAIT to TÜV SÜD and was carried out according to IEC 61400-1 ed.2. TÜV SÜD has already approved the MAIT document about the definition of the Design-Load Conditions and has issued the compliance of the blade design to the IEC 61400-1 standard. Furthermore, TÜV SÜD has already witnessed and certified back-to-back generator testing which has was successfully completed in 2011.

The prototype in the assembly area is one of four that went into initial service. A MAIT representative at the recent AWEA Windpower 2015 conference says the company is considering offices in the U.S.

In December 2012, the company acquired the authorizations relevant to the Monte d’Aria test site located in the Marche region (in Italy) in a complex terrain. The Monte d’Aria project includes four, 2-MW wind turbines. Two prototypes were assembled in the MAIT workshop and were scheduled for installation summer of 2014. The test measurements have been committed to WEST-lab (Wind Energy Studies and Testing laboratory) a facility of the Università Politecnica delle Marche.

The WEST-lab (Wind Energy Studies and Testing laboratory) will carry out the following test program in co-operation with the MAIT Wind Division:

- site calibration according to the IEC61400-12-1 standard

- set up of all the necessary sensors according to the IEC61400-11, IEC61400-12-1, IEC61400-12-2, IEC61400-13 and IEC61400-21 standard

- individuating the protocols and the tests measurements according to the IEC61400- 22 standard

- noise measurements according to the IEC61400-11

- Power Curve measurements according to IEC61400-12-1

- Power Quality measurements according to IEC61400-21

- loads measurements according to IEC61400-13

- Nacelle Transfer Function according to IEC61400-12-2

Filed Under: News, Turbines