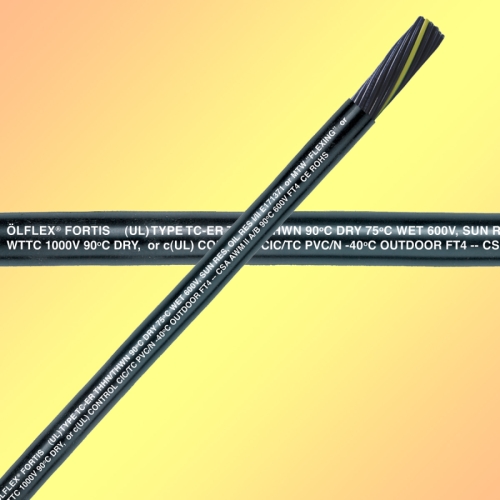

Florham Park, NJ – Lapp, introduces its highest-performance UL-listed tray cable, OLFLEX®

FORTIS. This product meets UL-1277 tray cable requirements, as well as providing industry-leading oil resistance and coldtemperature performance. It is also rated as a CSA tray cable (CSA C22.2 No. 230).

OLFLEX® FORTIS meets all requirements of UL-22 77 for 1000V Wind Turbine Tray Cable (WTTC). The excellent oil

77 for 1000V Wind Turbine Tray Cable (WTTC). The excellent oil

resistance is valuable for applications in wind turbine nacelles, and torsion resistance makes it perfect for cables in wind turbine

towers. Excellent cold-weather resistance allows OLFLEX® FORTIS to be used in wind turbines installed in arctic climates.

OLFLEX® FORTIS also offers outstanding performance at low temperatures. Excellent cold-temperature toughness and

flexibility make OLFLEX® FORTIS perfect for cold-weather installations or refrigeration projects. OLFLEX® FORTIS uses fine

conductor strands for superior flexibility during installation. This conductor also allows the product to be used in applications

with limited motion, like the torsion movement of cables in wind turbine towers. The copper core is sized for dual-rating to North American (UL) and European (VDE) standards.

OLFLEX® FORTIS meets UL’s OIL RES I & II as well as UL AWM 21098, allowing application in environments with long-term

oil exposure. OLFLEX® FORTIS has FT4 flammability resistance and passes the same crush and impact tests as armored

Metal Clad (MC) cables. The combination of outstanding oil resistance, mechanical toughness and tray rating allows it to be

used on machine tools, cable trays, and exposed runs between machines and trays.

Filed Under: Featured