Wind turbine service company Liftra launched the Blade Way in 2017 and introduced it at AWEA’s recent Windpower 2018 conference, as a way to remove and replace wind turbine blades without the time and cost expense of a high-reach crane. Blade Way has a rated capacity of 14.6 tons, and it can work at peak wind speeds of 12 m/s.

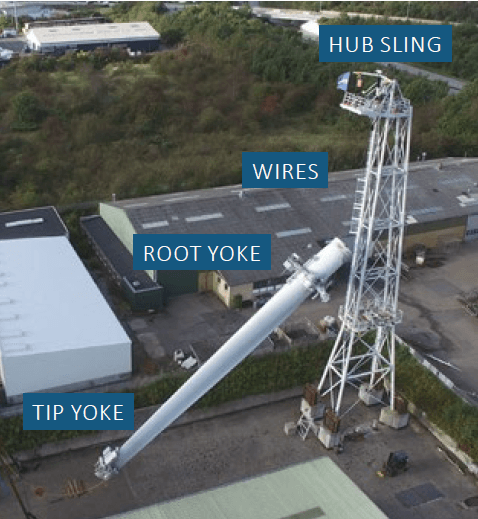

These are the main components of a Liftra Blade Way blade-removal system.

A few of its advantages include:

Reduced mobilization costs that come from its transport in just two standard 40-foot containers. It boasts of universal compatibility thanks to a system that is configurable for all major turbine brands. Its proven wire system and controls are based on the company’s self-hoisting crane. Also, proven blade yokes are based on the last seven years of development in vertical blade installation technology.

The system is comprised of two blade yokes, one for the root end of the blade and one for the tip end, and a hub sling and hoist block.

The components of the Blade Way include:

- Blade Way wire system at the turbine hub.

- A dual light-weight crane with two arms for hoisting the hub sling and hoist block.

- A steel A-frame that attaches to the container for gaining wire height, and the

- Wire system that runs from a winch in the container through the A-Frame and both blade yokes up to the hub sling.

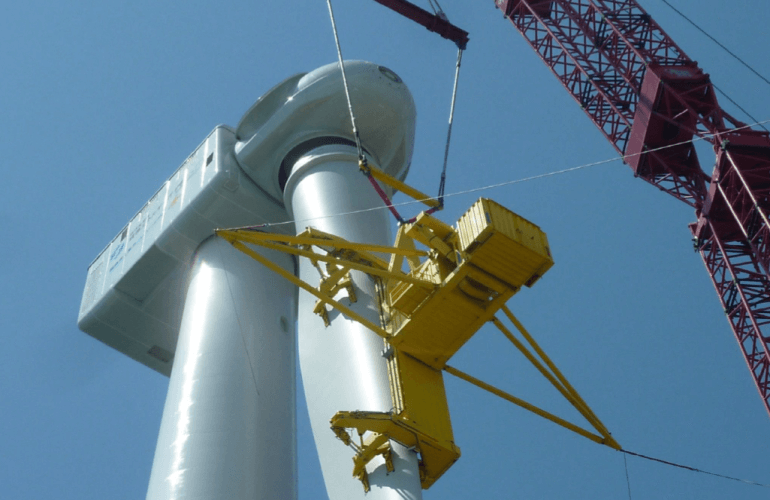

Blade Way brings down a blade for repair.

The Blade Way sets up at a turbine and removes a blade this way:

- Workers position the blade to be replaced by turning the rotor to position the faulty blade vertically.

- The dual light-weight crane is hoisted with the internal turbine crane and mounted inside the nacelle.

- With the light-weight crane, the hub sling system is hoisted and hooked around the two ‘bunny-ear’ blades.

- The root yoke and tip yoke are threaded and hoisted along the wires to each end of the vertical blade.

- The root yoke clamps the root end of the blade, and the tip yoke clamps the tip end, both at precisely defined positions.

- The blade is lowered to the ground, either with or without the blade bearing.

- Once on the ground, the blade or bearing is changed, and the blade can be hoisted back up and reattached to the hub.

Filed Under: Blades, News, O&M