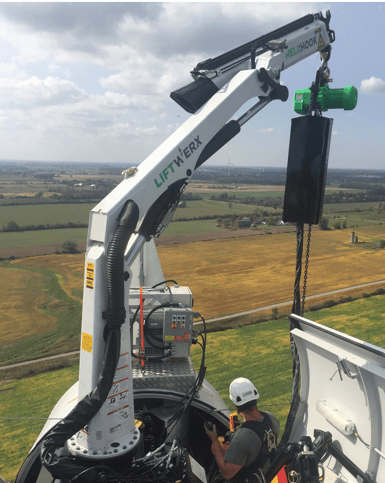

LiftWerx announced that it has partnered with Siemens Gamesa to develop what’s currently the world’s highest capacity, uptower lifting device. Rated at a lifting capacity of 75 tonnes, the RotorHook is designed to lower and lift a fully assembled wind-turbine rotor and main shaft.

RotorHook will launch in the second quarter of 2019 and, according to LiftWerx, is currently the largest uptower lifting device to be developed in the wind O&M industry.

The device will eliminate the need to use a large conventional crane, easily mobilized to project sites in only three standard ISO containers, and help set a new standard in performing major component corrective repairs. Launching in Q2 2019, LiftWerx says the RotorHook will drive down O&M costs, improve turbine uptime, increase safety, and reduce the reliance on larger, more costly cranes.

“We are excited to partner with LiftWerx because their technology will set a new standard for main bearing and generator exchanges,” said Ted Pruss, Director North America Operations, Siemens Gamesa Renewables. “This is a big step forward for the industry where continuous innovation and lowering the cost of energy continue to be market drivers.”

In addition to lowering O&M costs, LiftWerx’s uptower lifting technology will reduce ground preparation and downtime by allowing safe operation of major components in higher wind speeds. The design and production of the RotorHook will be performed by the Kenz-Figee Group, in close co-operation with Eager.One for specialized engineering. LiftWerx, Eager.One, and Kenz-Figee are subsidiaries of the Meemaken Group.

According to Paul van der Weg, Head of Advanced Operations Support, North America, Siemens Gamesa Renewables: “I am confident that the combination of LiftWerx’s experience in providing both conventional and innovative solutions to the wind industry, and Siemens Gamesa’s operational and turbine specific expertise, will result in a solution that will set a new benchmark for the industry.”

Filed Under: Components, Construction, Hydraulics, News, Towers