In 2008, at the start of the great recession, your humble narrator was presented with a great opportunity: helping to start a new magazine. You might wonder how many magazines your average editor gets to launch in a career. If they are extremely lucky, one.

It happened to me. The magazine begun here at WTWH Media focused on the wind industry. This was fortuitous because of a secret affection and fascination with wind turbines. As a product of pinch-penny parents, I thought a machine what would turn free wind into useful electricity seemed absolutely sublime, and it still seems so today. And so for the last nine years, it has been my privilege to follow a brand new industry with a potential we are still just grasping.

But nothing lasts forever. You have probably heard of the seven-year itch. Some say after seven years in the same job, a person gets, for lack of a better term, stale. Personal energy wanes and interests change. So the time has come for new ideas and enthusiasm. I’ll retire after the June issue of this magazine and leave its editorship in the capable hands of Michelle Froese.

But before leaving, I’d like to look back at what may be the five most significant developments in those nine years. These events show where we have been and remind us how far the industry has come. In no particular order my top five picks are:

- Torque control in wind-turbine drivetrains. Elimination of damaging torque spikes in a drivetrain lets gearboxes work well beyond the usual three to four years.

- Launching the U.S. offshore wind industry.

- Vastly improved condition monitoring, which could include AI

- The rise and fall of the production tax credit.

- Flying and crawling drones that will take much of the hazard out of wind-farm maintenance

Looking ahead is always fun but humbling because real life rockets past our usually feeble linear predictions. Still, these five nascent technologies will likely propel the wind industry well beyond the size and production capacities of where it is now:

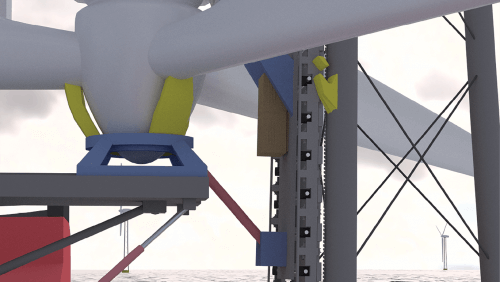

One example of an automated construction technique comes from the UK’s Energy Catalyst and its Self Erecting Nacelle System, or SENSE.

- The 10-MW and larger turbine. Hold the phone, you say. GE has announced a 12-MW unit. That is true. You may recall that eight years ago, at least three manufacturers had announced 10-MW turbines. Read about one here: https://tinyurl.com/Clipper10. Ten megawatts is a significant technological hurdle because of the enormous stresses such large machines will have to endure. Moving much beyond 10 MW will require quite different design ideas and a few significant developments. Nonetheless, the effort will be worth it because a single 12-MW turbine could replace six 2-MW units, which are about average for today’s ratings.

- Modular blades and towers. These will trim transportation costs.

- IIoT, the Industrial Internet of Things. This sounds like a fancy name for a network with more smarts built-in. But it is more than that, and it is taking shape slowly. We have heard of only one good application so far: Monitoring utility power-purchase prices on a second-by-second basis and triggering a cost-saving response to the supplying wind farms.

- Artificial intelligence. AI will lead to more accurate predictive maintenance and hundreds of other cost-cutting inventions.

- Automated turbine construction. Several good ideas today could obsolete costly 100-m tall cranes and the 11 trucks needed to transport the crane sections.

The industry is headed in the right direction. As expensive as offshore wind farms will be, offshore is the right place to go because it gets away from cranky people and into more powerful winds. A recent report, for instance, tells of a remarkable 65% capacity factor for the floating Hywind wind farm off the coast of Scotland.

More good news: there are lots of good ideas for taking cost out of construction, O&M, and eventually the cost of power. You’ll see some at the upcoming AWEA Windpower 2018 conference in Chicago.

It’s not hard to see that the future is electric and it’s generated by wind. Goodbye and good luck, all you wonderful readers.

- Paul Dvorak

Filed Under: Featured