This article comes from the ABB Review and is authored by Antonio Fidigatti, Paolo Baroncelli, Marco Carminati, and Enrico Ragaini

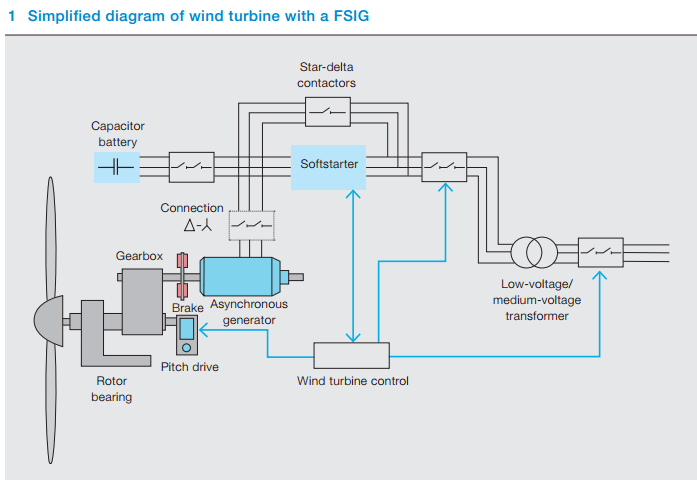

Wind turbines come in different designs, each with its own electrical behavior that needs a unique approach when it comes to switching and protection. A review of the three most common turbine designs reveals the important factors to be taken into consideration in the choice of switching and protection components.

More than 150,000 wind turbines are currently installed worldwide. Over 90 percent of these generate electrical power at low voltages, less than 1,000 V.

More than 150,000 wind turbines are currently installed worldwide. Over 90% of these generate electrical power at low voltages (≤ 1,000 V).

The electrical protection and control systems that are so critical to keeping wind turbines running safely present conflicting requirements related to conversion efficiency, production continuity, fault disconnect, climatic and mechanical constraints, compactness and the need to reduce the effects of faults in the tight space inside the nacelle. Conversion efficiency Wind speed and direction can change rapidly or the wind can drop altogether so the turbine’s mechanical and electrical configuration must be capable of rapid adaption. This causes frequent operation of control actuators (eg, for pitch adjustment), which, in turn, produces repeated connection and disconnection of the power circuit, with the attendant risk of component overheating.

Power production continuits

This requires high reliability during the entire lifetime of the wind turbine. The difficulty of physical intervention makes high reliability even more desirable. A good strategy here is to use components for their main function only (eg, circuit breakers for protection, contactors for switching, etc.) rather than trying to squeeze secondary functions from them. Generous tolerances are also obligatory.

Fault-disconnect behavior

The need to guarantee linear behavior even during network disturbances has led to the definition of grid codes, compliance with which is mandatory. In many cases, the control of reactive power flow under standard service conditions as well as under disturbed conditions requires a high number of operations by the connection devices of capacitor banks and filters.

Climatic and mechanical constraints

The environmental stresses suffered by a wind turbine can be severe: Vibrations can be of several millimeters’ amplitude and thermal conditions can range from below –25°C when heating and de-icing functions are switched off during inactivity to 50°C when power-dissipating components are operating in overload conditions.

The aging effects of this operational environment as well as the effects of frequent switching, salt air, humidity, pollution, etc., must be taken into account in lifetime calculations. Further mechanical constraints are linked to the requirements for compactness and low weight because of the limited space available in the nacelle and the need to minimize mechanical stresses on the structure. These factors necessitate trade-offs with the over-dimensioning quired for high efficiency and service continuity.

Faults in the nacelle

For the rest of the 5 page article: https://goo.gl/o0QxCI

Filed Under: O&M