This article comes from gearbox manufacturer Moventas

In the constant pursuit of reducing the overall weight of the wind turbine mass, Moventas’ engineers have discovered an innovative power-density concept based on proven designs. By designing it compact and extremely lightweight, our state-of-the-art gearbox provides a significant reduction of tower head mass. The need for drivetrain space in the axial direction is equally reduced by the power density concept. All reaction forces can be transmitted to the nacelle structure in an optimal way. The concept also ensures that there is no need for separate support structures for the generator.

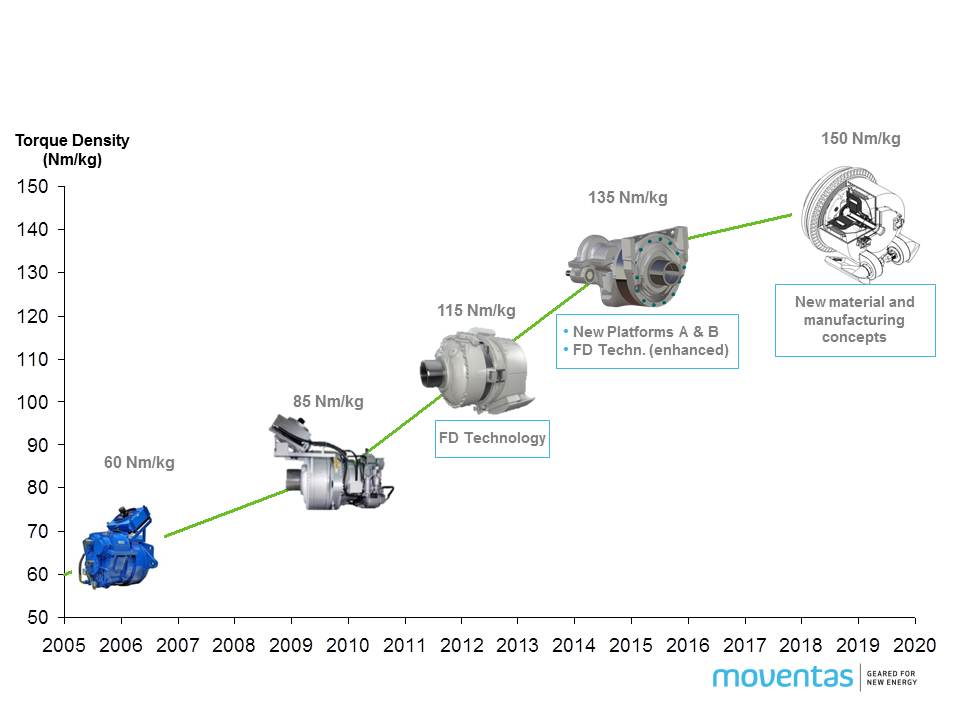

The torque versus power density for Moventas gearboxes has risen steadily and quickly over the years.

Torque density is used to measure gear performance. It states the level of torque one kilogram of material, used for gear unit, can carry. Lowering the mass influences also to gear dimension, so density correlates with mass. Moventas’ expert gear design skills and application know-how with improved materials allow higher gear torque density for new gear unit designs.

Noise & vibration

Moventas has successfully reduced the noise level of its gearboxes by improving tooth accuracy and choosing the optimal geometry and profile. Theoretical evaluation as well as on-site testing is used to eliminate any harmful resonance sounds of the structural elements. To achieve noiseless wind power, the gear unit must not vibrate. Therefore, our gear units are especially designed to prevent vibrations from passing through the gearbox fixing points to the foundation of the wind power plant.

Verification

The Moventas product portfolio is the result of proven technology including modular components for all drivetrain solutions. Moventas planetary gear consists of our special knowhow of e.g. integrated bearings, case hardened ring wheels and Flexspider technology. Our product concepts are based on approved methods of regulatory agencies.

All the gear units are verified by tests and measurements. Moventas has vast experience from prototype testing and qualification. During the last decade we have performed over one hundred modern wind turbine gear prototype test in MW class alone. Typically prototype gear units go through lifecycle and cold climate chamber tests. We also use virtual prototype environment to define drivetrain dynamics.

Moventas

www.moventas.com

Filed Under: Components, Gearboxes, News