Wind turbine gearboxes are a little more reliable since researchers at The Timken Company have been able to reproduce smearing damage on bearings in the lab. Producing it means they know what causes it, and later tests on selected surface treatments show that one works well eliminating the damage.

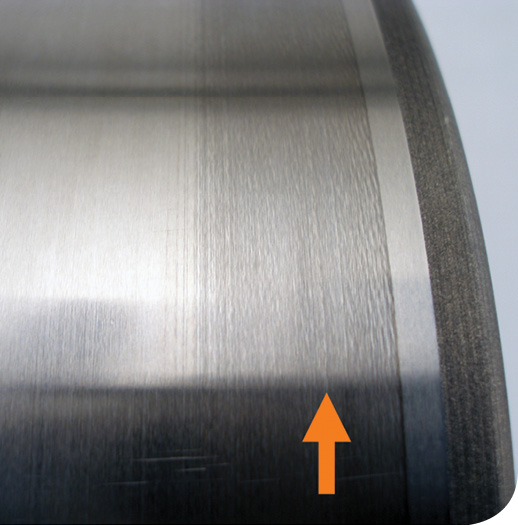

Smearing is characterized by the appearance of skid marks around a raceway circumference, with mild plastic deformation of the material surface, and the potential for adhesive wear and material transfer.

“Smearing is a damage mechanism in rolling-element bearings caused by roller skidding,” says Timken’s researcher Ryan Evans. “It’s characterized by a skid-mark type of appearance around a raceway’s circumference, with mild plastic deformation of the material surface, and the potential for adhesive wear and material transfer.”

Damage bands from smearing may change the original engineered surface texture and profiles of the bearing raceways, potentially leading to more advanced adhesive wear. It also serves as initiation locations for spalling damage.

So which bearings are most susceptible to smearing? “Rolling element bearings with inherently higher roller-raceway slip are most susceptible to smearing damage. More specifically, spherical roller bearings and cylindrical roller bearings are more at risk than tapered roller bearings,” says Evans.

Wind turbine gearboxes use many cylindrical roller bearings. Their damage risk is magnified when bearings operate at high speeds and low loads, as in small or erratic load zones – those with rapidly changing conditions.

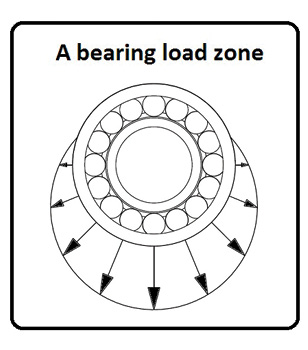

When a shaft loads a bearing in normal conditions, the rolling elements enter and leave the load zone with shaft rotation, effectively transmitting load mostly through that portion of the raceway about the 6 o’clock position. If the shaft loading dynamics change, say from from down to up, the load zone location also changes and creates an erratic load zone condition that can significantly increase smearing risk.

Rolling element bearing performance is most predictable when things are working well, in steady state for instance. “But consider two bearings supporting a rotating heavy shaft influenced only by gravity. In this case, the bearing load zone will be in the 6 o’clock direction and the group of rollers carrying the shaft load will span an angular range around 6 o’clock. The rollers in the 12 o’clock position are effectively unloaded against the raceways. So with shaft rotation, rollers are loaded and unloaded as they pass into and out of the load zone. If this steady situation is disturbed in some way that tips or dynamically impulses the heavy shaft in an unsteady way, such as by a vibration or torque event (from a gust) that passes through the shaft, it can momentarily unload the originally steady 6 o’clock load zone in the bearing, either changing the angular span of the load zone around the 6 o’clock location, or even moving the load zone to the 12 o’clock position,” says Ryan. Generally, any transient change in the load zone width or angular location compared to steady conditions can be regarded as an “erratic load zone”.

As with most component wear or damage, the best way to solve a smearing problem is to eliminate the root cause, which is severe roller slip. Evans’s team evaluated several surface treatments and found that for the severe conditions studied, a roller coating identified as WC/a-C:H, offered the best protection against smearing damage. “The material contains both ceramic and polymer constituents situated on a nanometer-length scale, in other words, an engineered nano-composite,” says Evans. He also suggests that follow-up studies might evaluate other factors that can influence smearing risk, such as steel type, heat treatments, lubricant-additive formulations, and various other load and speed conditions.

For a digital copy of the entire August issue of Windpower Engineering & Development, pick here: http://goo.gl/9dlckH

Filed Under: Bearings, News

MOFLON, a slip ring company, has been working on slip ring solution for over 10 years, with rich experience of production and designing. More information, please check: http://www.moflon.com