One trend in manufacturing is to procure more than an unfinished component from a supplier. The idea of one-stop shopping has reached manufacturing firms for a good reason: OEMs want shorter supply chains. The fewer shops a part must visit on its way to a finished machine, the more likely it will arrive in better working order, and it will cost less. Take Spanish manufacturing firm Sakana, for example. Its OEM clients asked it to add more value to their components by taking responsibility for more of the manufacturing process.

The company, a gray and ductile-iron-casting firm in north Spain, received this opportunity from its wind-turbine customers. After it casts components, most need machining and painting. OEMs asked the company to add the steps to its scope of supply …if they wanted to continue supplying these parts and remain competitive. The foundry, however, had no experience in either task.

Sakana executives briefly considered the alternatives of subcontracting out to other companies. But here was a chance to add machining and painting to their capabilities portfolio. It would require an investment upwards of $26 million (20 M€), but could place them in position to receive for more of this kind of work. The payoff would be to gain flexibility in the production required for clients, adapt quickly to changing design requirements, and cost efficiencies from performing several processes at one industrial site.

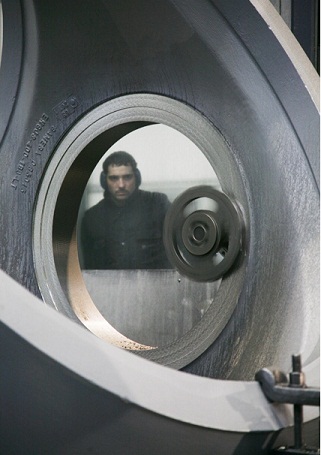

A Soraluce boring mill (left) machines a frame in the background. A large casting in the foreground awaits machining

Sakana decided to go ahead with the plan. A new foundry would have a capacity of 16,000 ton/yr dedicated to the large wind engineering components, leaving the remaining capacity, another 16,000 ton/yr, for smaller parts.

To integrate machining process, Sakana managers went looking for a company that could supply most everything it needed – one that could combine boring mills, and clamping fixtures, machining ops, and even responsibility for the execution of the first components to train crews and assure the first contract as well as the launch into production.

The company found what they were looking for in Soraluce, a manufacturer of boring mills. The company also manufactures machines such as heavy-duty mills, horizontal and vertical turning centers, and grinding machines.

Soraluce’s expertise in this turn-key project helped it define the requirements for the essential equipment, then it recommended accessories useful for production, and it even devised a layout for the plant with a description of the general equipment that would be implemented later.

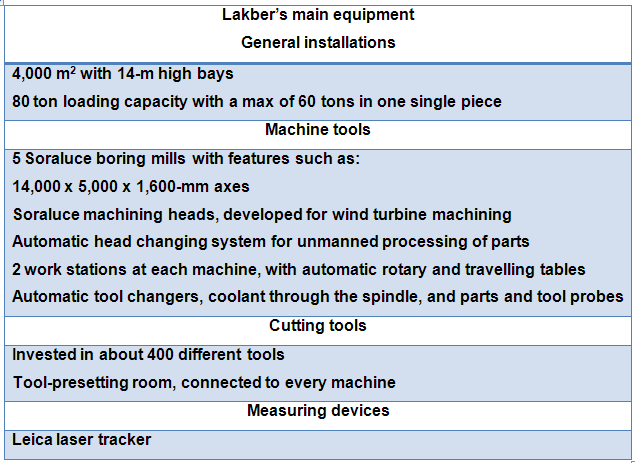

Finally in 2008, the new facilities opened its doors under the name Lakber (as a subsidiary of Sakana) showing a state-of-the-art plant focused on wind-turbine components and a capability for mass production as well as prototype machining.

New tools make daily tasks faster

It is not easy to take components that weigh eight to 24 tons and machine off about two tons from each, all the while taking care of the cost per component. One scrapped part could mean losing the profit from months of work.

Lakber is, of course, equipped for hub and frame manufacturing. The work uses the most reliable machinery for stringent requirements. The division also has available technology to ease daily tasks and help employees focus on value-added activities. The company provides state of the art capabilities thanks to technologies including an:

- Intelligent cutting-tool magazine with a tool pre-setter connected to machines

- In-house developed ERP to control production costs, schedules, and to ease planning.

- NC software to get designs into production. The software connects to the general-tool magazine and machine-specific tool magazines. This cuts time often wasted looking for “lost” tools in the workshop.

- Measuring equipment connected to a database that generates custom check-list sheets for every component.

Relationships start with manufacturing

The relationship between the company and its customers starts with manufacturing. A test for some components is to machine them to determine whether the initial process is reliable or not. This decides the future of the relation.

Lakber General Manager Alejandro Martinez says it got a contract for 10 prototypes in their first year. The first challenge for the hub-and-frame manufacturer was to find a good machining process that can assure little compromise between the needed finish tolerances and the best cycle time.

“In two years, we turned an idea into a reliable hub and frame manufacturer,” he says. “The technical responsibility for machining in this first project fell on Soraluce, a technically savvy company that provided us with the required advanced-machining equipment and their know-how in turn key projects for wind-turbine components,” adds Martinez. “They provided us with boring mills, the fixturing, the machining process, the cutting tools, NC machining programs, and useful knowledge.”

“From the beginning of the project we had a collaborative engineering relationship with Soraluce to update our knowledge, from almost zero, to a leading position in hub and frame machining,” adds Martinez.

For instance, everything starts with the speculations for the finished component: required final tolerances, reference points, and best clamping areas. All this calls for an optimized machining strategy with the minimum set-ups, because these larger components are not easy to handle. “This is something that you can only achieve when you have a trained and motivated team working for the best technical solution in terms of process and cycle time. You oblige yourself continuously improving the process by means of regular benchmarks on tooling improvements and accessories for the machines. And you have open discussions about the machining matters with your customers to find solutions that fit better with their philosophy and technical principles.”

Filed Under: News