Allan Steinbock, VP – Sales, Superbolt Inc.,www.superbolt.com

The cutaway of a multi-jackbolt tensioner shows how tightening the jackbolts puts the main bolt in pure tension

Nuts and bolts may be the most common elements in any piece of machinery. They’ve been around so long the average person doesn’t give the technology much thought. Engineers, however, know better.

The wind industry presents several bolting challenges. It’s critical to get tower and turbine joints tightened correctly and in the safest, most economical way possible. But it’s not always easy.

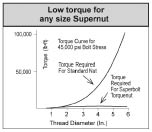

The problem is that the amount of torque required to attain a given preload increases exponentially with bolt diameter. As a result, special tooling, such as hydraulic wrenches, is usually needed to generate a required preload. For wind turbines, this means lugging expensive and heavy tooling up to some pretty interesting places. Such methods can also cause problems with joint integrity, or do not provide consistent bolt load across the bolted surface. The bottom line: It’s no small task to generate preloads on large diameter, hex-head bolting with conventional hex nuts.

One alternative to using high-powered tools on existing nuts and bolts is the Multi-Jackbolt Tensioner (MJT). Rather than turning one large nut or bolt to obtain preload, MJTs use a number of smaller jackbolts threaded through the tensioner body. The benefit is that any size MJT tensioner can be installed and removed using a hand-held, electric or air-powered torque wrench. This is a huge advantage in wind turbine work because towers and nacelles makes it difficult to use heavy tooling.

How they work

The MJT consists of three components – a hardened washer, a tensioner nut body, and jackbolts. The jackbolts thread through the round tensioner body, or bolt head, and thrust against the hardened washer to stretch the stud/bolt and generate clamping force.

The torque needed to tighten each jackbolt tends to be small and easy to generate, thus enabling use of hand tools. The preload generated is directly proportional to the size and number of jackbolts used.

Benefits

There are several benefits when using MJTs. Besides increased worker safety and smaller tooling, the tensioners improve the entire bolting system. For instance, torquing conventional nuts and bolts can twist the main bolt, adding unwanted internal stresses and reducing its load capacity. MJTs tighten in pure tension, so there is no torsion on the main bolt. Also, because the main thread does not slide under load, there is no thread galling or seizing.

Another problem with hex nuts and bolts is that there’s a high stress concentration found on the first few threads. By comparison, the jackbolts in the MJT system create hoop stresses in the nut body, so the nut flexes out slightly at the bottom and in slightly at the top. This flexing distributes load throughout the entire thread engagement and adds elasticity, which means short, stubby bolts are much less likely to break from fatigue stress.

One possible drawback to the MJT system seems to be the number of jackbolts that need tightening. One might think they would result in longer installation and removal times. Surprisingly, the opposite is true. The MJT system has been proven to reduce installation and removal times. For example, a 1.5-in. tensioner can be installed and tightened in about 1 min. 29 sec, while a 2-in. tensioner would take about 1 min. 33 sec.

One possible drawback to the MJT system seems to be the number of jackbolts that need tightening. One might think they would result in longer installation and removal times. Surprisingly, the opposite is true. The MJT system has been proven to reduce installation and removal times. For example, a 1.5-in. tensioner can be installed and tightened in about 1 min. 29 sec, while a 2-in. tensioner would take about 1 min. 33 sec.

So, if you are having problems bolting a critical wind turbine joint, or want to make bolting easier and safer for workers, the Multi-Jackbolt Tensioner system could be a viable alternative.

Filed Under: Components, Turbines