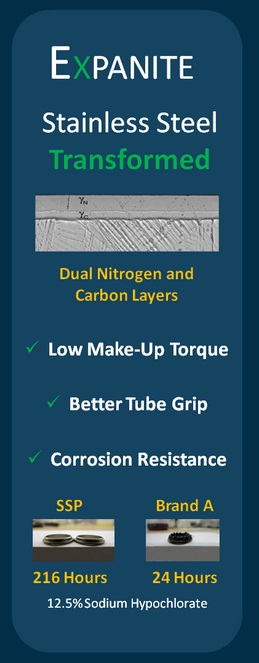

Expanite provides two layers of corrosion protection.

A U.S. manufacturer of instrumentation fittings announces global and proprietary rights to the Expanite process of hardening stainless-steel fittings while improving corrosion resistance. Fitting must not leak in highly corrosive environments such as chemical process and oil & gas applications. In addition to improving fitting performance, installation is easier with less make-up torque due to reduced friction, thereby reducing worker fatigue.

The Expanite process, developed and tested by Thomas S. Hummelshoj at the Technical University of Denmark, uses a patented method for surface hardening of stainless steel. Expanite is not a coating, but a process that impregnates the stainless steel surface with carbon and nitrogen.

“Adopting the Expanite process lets the company offer industry-leading performance of our instrumentation tube fittings, especially the critical back ferrule,” says SSP CEO Jeff King. “Additionally, our worldwide network of distributors can be confident their properly installed, precision machined fittings and specification controlled tubing will offer leak-free, industry-standard performance.” See performance study and more information at http://info.mysspusa.com/Expanite-Superior-Corrosion-Resistance

SSP

mysspusa.com

Filed Under: News, O&M