Craig Collier

President

Collier Research Corp.

hypersizer.com

Tom Ashwill

Technical Leader

Wind Energy Technology Department,

Sandia National Laboratories

windpower.sandia.gov/

Commercial wind-turbine blades have historically relied on fiberglass as a primary material. In 2010, a Sandia National Laboratories’ report estimated annual U.S. industry usage for utility-grade turbine blades at over 70,000 metric tons. As designers build bigger blades in an effort to boost power production and cost efficiency, material systems are evolving to account for the increasing weight and additional gravitational stresses. Engineers are now looking to high-performance composites for greater strength and lighter weight at competitive prices. But consider that a typical 1.5-MW blade is 33 to 40-m long, weighs up to eight tons, and can have composite layups as thick as 4-in. at the root. Now you begin to grasp the engineering challenge inherent in designing an efficient, cost-effective composite blade.

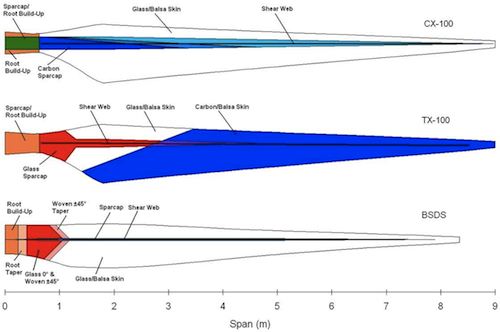

The blade planforms with major material regions are for Sandia’s three wind-blade prototypes: CX-100 (carbon experimental), TX-100 (twist-bend experimental), and BSDS (blade system design studies). (Illustration from Sandia National Laboratories’ Materials and Innovations for Large Blade Structures: Research Opportunities in Wind Energy Technology, AIAA- 2009-2407, May 2009)

Since the early 2000s, Sandia’s Wind Energy Technology Department has been conducting prototype projects to develop and evaluate a variety of innovations for wind blades, including new material systems, more efficient structural architectures, load alleviation methods, and thicker airfoils for increased structural performance. A program currently underway at the government lab explores the design of a 100-m blade (potentially for a 13.2-MW turbine) targeted for offshore use and asks the difficult design and material-system questions that accompany increasing blade length.

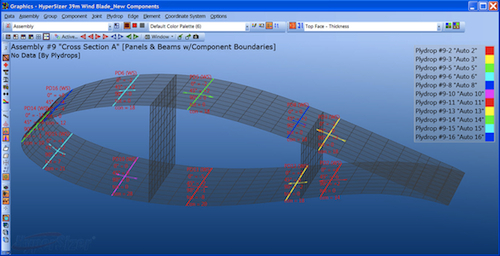

The cutaway of Sandia’s BSDS (blade system design studies) prototype shows a few internal details. Carbon is used for the primary load-bearing spars with a sandwich-style fiberglass construction for the blade skins and shear-webs panels. In this configuration, the spar caps were primarily unidirectional carbon fibers and the skins were typically biaxial or triaxial fiberglass. (Illustration from Sandia National Laboratories’ Blade System Design Study Part II: Final Project Report (GEC), SAND2009-0686, May 2009)

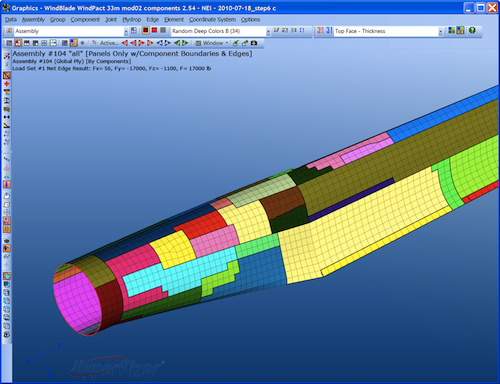

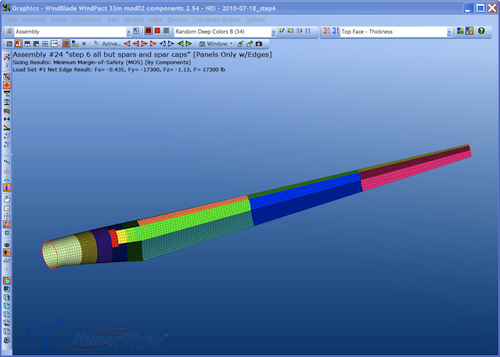

To help answer some of the questions, Sandia will be working with Virginia-based Collier Research Corp., to apply its composite analysis and optimization software to large-blade-prototype designs. The software, HyperSizer, a NASA technology-transfer spinoff, has been used extensively by the space agency (in the ARES V launch vehicle and Composite Crew Module) and in aircraft to structurally size complex composite and metallic designs. The software complements finite-element analysis (FEA), working in a feedback loop with commercial codes to search for solutions that minimize weight, while maximizing strength and manufacturability—all issues critical to wind-turbine design.

Asking material questions

In place of fiberglass, or glass fiber-reinforced polymer, blade designers are turning to carbon fiber-reinforced polymer for its superior weight-to-strength characteristics. Carbon fiber is already used extensively in the aerospace industry—in the Boeing 787, Airbus 350, Bombardier LearJet 85, and Goodrich engines—where higher strength, lower weight, and greater fuel efficiency are design goals.

A hypothetical model (left) is for a wind turbine blade with manually defined laminate zones showing rectangular layup sections based on generalized rules of thumb. Colors represent different zones. Note only a few sections in the blade root. In a detail of the blade root (right), HyperSizer software was used to redefine zones by surveying thousands of surface area shapes and sizes. While creating optimum zone shapes of laminate transitions, it also minimizes ply drops in zone transitions.

The question of when and where to substitute carbon for fiberglass in a wind blade is not simple. For one thing, even though carbon fiber is significantly stronger and stiffer than fiberglass, it is much more expensive. Also, an extensive library of glass and carbon fabrics and tapes with varied fiber orientation, strength, and rigidity, as well as a host of sandwich cores and hybrid laminates with diverse properties, makes materials decisions even more difficult for designers. Tremendous variation in internal loads along the length of a wind blade further amplifies the complexity of the material system design.

To help unravel design uncertainties, Sandia’s past prototype projects focused on the use of carbon fiber to control the loading scenarios of increasingly bigger blades. The CX-100 (carbon experimental) contained a full-length carbon spar cap – at the time a relatively new concept. The TX-100 (twist-bend experimental) used both a fiberglass spar cap that ran only half the length of the blade and unidirectional carbon fibers in the skins to passively shed aerodynamic loads through twist-bend coupling. The third prototype, the BSDS (blade system design studies), also used a full-length carbon spar cap, but experimented with airfoil shapes and dimensions of the root. The current 100-m blade study focuses on designing an all-fiberglass composite blade that can withstand international certification loads including operational, fatigue, and buckling, as well as manufacturability considerations.

While Sandia’s research is advancing blade technology and seeding industry innovation, there are still many gaps in knowledge and practice. Design areas ripe for innovation and optimization include material type, material placement, internal architecture (number of shear webs, spar cap thickness, and more), and airfoil planform. Where materials are concerned, because loads vary over a wind blade’s root, spar, shear webs, and free-flowing surface, it is difficult for a designer to know what shape to make a laminate zone, where to stop one zone and start another, or how to determine an optimum thickness of layups in different zones. It is also difficult (almost impossible) to manually calculate how to handle transitions between zones and where to position many individual ply drops and adds in a single blade. Resin and layup process variables introduce even more complexity and signal a need for additional design tools.

The ply-compatibility analysis conducted in HyperSizer quantifies how ply drops and adds are minimized along panel transitions.

Magnifying material answers

A material design model typically starts by mapping rectangular-shaped sections for the laminate zones, based on accumulated knowledge and rules of thumb. But the reality of buckling, bending, twisting, deflection, and aerodynamic loading is anything but regular. Software such as HyperSizer helps. Using blade-loading results from FEA, the software maps the laminate zones to more accurately represent the blade physics and then calculates a ply stacking sequence for each zone.

To accomplish this, FEA is first run to determine internal loads and deflections in the blade. Those loads are then imported into HyperSizer, which performs tradeoff studies, surveys thousands (or sometimes even millions) of candidate laminates, and exports the new material properties. Then the FEA model is rerun

As part of the analysis, the software performs a sizing optimization, failure-and-fatigue investigations, and weight-trade studies. It also calculates margins of safety (factors of safety) and best configurations for transition zones. Surveying designs in a ply-by-ply and even finite-element-by-element manner, the software leads users to customized laminate solutions early in a design process, using a wide variety of composite materials.

A typical analysis and optimization takes about four hours, while eliminating offline spreadsheets and manual calculations. The software can also exchange laminate specifications with CATIA and FiberSIM.

The three blade profiles provide scale for the 13.2 MW, 100-m prototype wind blade in development at Sandia National Laboratories Wind Energy Technology Department. Each colored patch on the blade model illustrates a laminate zone.

Wind’s material future

There is currently no “best design” configuration for wind turbines. The engineering community is still searching for the right combinations of structural innovation and complementary material solutions.

But when Sandia’s prototype blade research first started in 2002, engineers didn’t even know if they could mix carbon fiber with glass fibers because their strength properties differed by a factor of three. Now they know a combination of advanced materials including carbon fiber, hybrid laminates, and sandwich cores of all material types can play important roles in blade design. Along the way they have accumulated more than 10,000 fatigue-test results for about 150 different composites, all of which can be downloaded into the software’s material database

Analysts at CompositeWorld’s 2009 Carbon Fiber Conference agreed with Sandia researchers’ findings about the value of new materials. They predicted that by 2014 wind blades will be consuming 35,000 to 50,000 metric tons of carbon fiber annually.

As wind technology matures, engineers are learning how to build longer, stronger, and lighter blades using the latest high-performance composites. Advanced analysis tools, such as HyperSizer, will accelerate that learning curve. The software’s track record in the aerospace industry has been weight reduction averaging 20%. Test cases on wind blades are yielding similar results.

WPE

Filed Under: Blades, Components, Turbines

Dear sir/Mam

I am dhilep am working in Wind farm company i want this software how to download tgis wind blade design software please help me give some ideas am expect u r valuable replay