Mentor Graphics Corp. has announced the latest release of FloEFD, its computational fluid dynamics (CFD) software. The new release provides advanced capabilities and functions that let designers and analysts create more realistic operating environments and models for improved simulation accuracy. New features include a sliding mesh model for rotating equipment such as pumps, fans, and blowers; water film simulation to calculate surface condensation and icing film thickness; together with radiation and lighting enhancements. These new capabilities support automotive industry initiatives for developing state of the art lighting products as well as enabling manufacturers to design better pumps, fans and blowers.

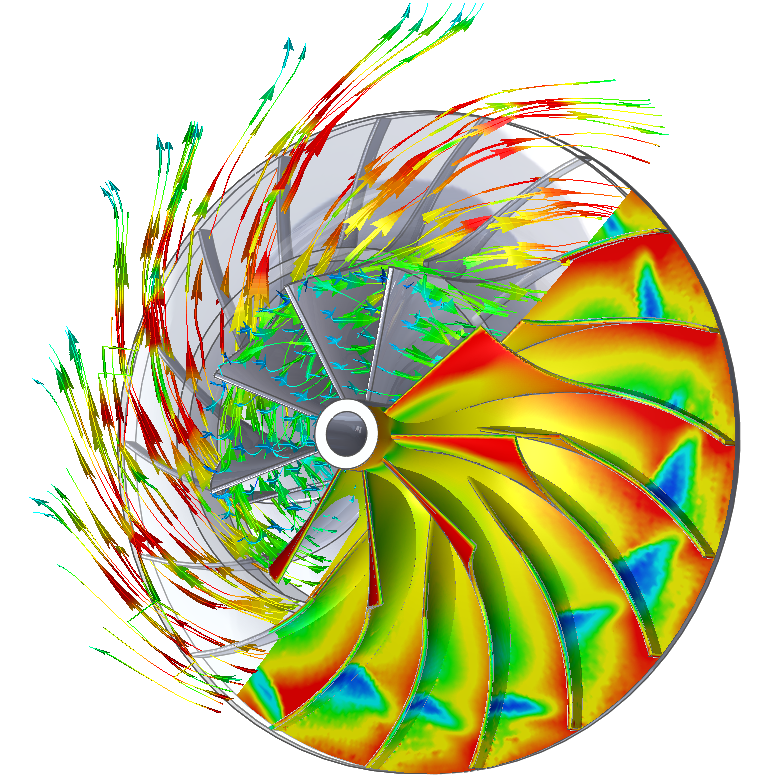

Sliding mesh modeling which lets users create more realistic simulation of rotating equipment when fluid quantity is highly non-uniform around a rotating part, such as a pump or fan.

“I am pleased to let you know that Tamturbo Oy Ltd. has been successfully using FloEFD for high speed compressor CFD simulations. Test models show that the new sliding mesh rotor-stator interface model is accurate and can be used for high speed compressor simulations” said Jaakko Sailakivi, CTO. “In addition, I have also found technical support from Mentor Graphics to be very professional. The combination of powerful general purpose upfront CFD analysis capabilities and fast technical support has enabled us to use FloEFD as the primary CFD solution in our company.” Tamturbo Ltd. manufactures high speed compressors for use in food production as well as chemical and medical industries.

The FloEFD product is a leading general-purpose CFD software solution for the mechanical design market, and the new enhancements were developed to help engineers create more accurate simulation environments for their products. New key features include:

- Sliding mesh modeling which lets users create more realistic simulation of rotating equipment when fluid quantity is highly non-uniform around a rotating part (such as a pump or fan) and cannot otherwise be calculated with circumferential averaging.

- Surface condensation and evaporation, the new water film model, is valuable for situations where surface condensation, evaporation, icing and de-icing exploration is essential, such as condensation on the inner surfaces.

- Enhanced radiation modeling: The new ray-based (band-less) spectral model for lighting and radiation lets users significantly decrease time required for defining wavelength-dependent properties while increasing simulation accuracy of spectral characteristics. Gaussian surface reflection for more precise simulation of reflected radiation is also included. Inclination of solar rays from the parallel can now be taken into account too thus allowing capture of solar radiation in greater detail.

- Usability and visibility enhancements: The new release of the FloEFD product features an improved parametric study capability. It allows the user to group input variables to simplify scenario definition, filter parameters, highlight impact on results of a specific parameter, and conduct built-in comparisons thus increasing parametric study efficiency and dramatically decreasing the size of the stored data when hundreds of variants are calculated.

- Improved visualization: The addition of GPU-based dynamic trajectories let users highlight flow details better and easily adjust the animation speed as well as appearance of trajectories in real time. A popular MPEG-4 codec has also been added for the creation of animations without enormous amounts of disk space.

Mentor Graphics

www.mentor.com/products/mechanical/products/floefd

Filed Under: News, Software, Turbines