NRG Systems has expanded its products to wind-energy operations and maintenance segment. Its patented TurbinePhD system monitors the health of turbine components for more cost-effective operations and maintenance.

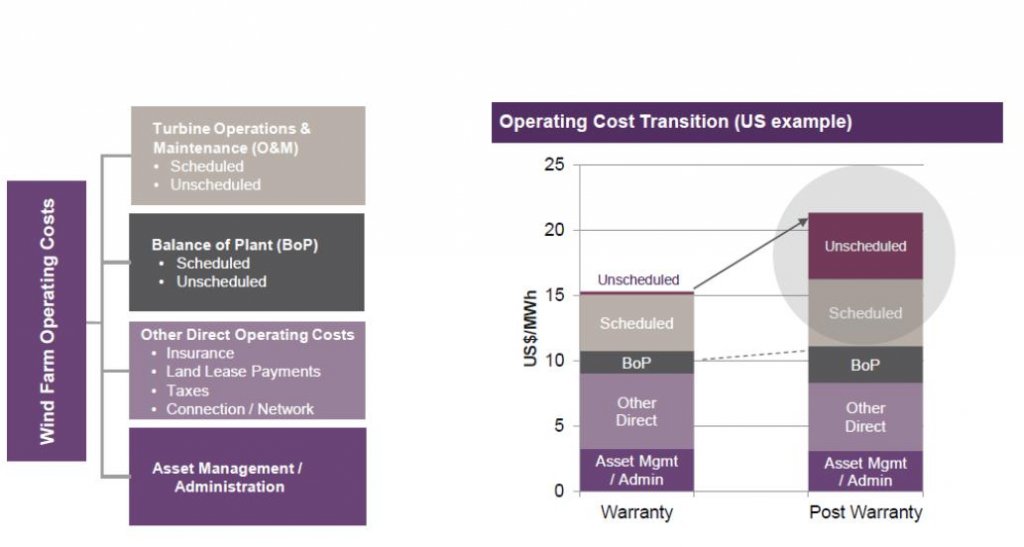

Wind farm operating costs as supplied by a US asset owner.

“Our system borrows technology from the aerospace industry to diagnose early-stage wear —months in advance of a fault—and then to accurately estimate the remaining useful life of each component,” said Eric Bechhoefer, chief engineer at NRG Systems. “We also eliminate the need for a diagnostic engineer by integrating data into a single, readily understandable health indicator for each component. The data can be read and acted upon by anyone.”

A new gearbox goes in because sometimes, SCADA is not enough. NRG Systems is finished beta installation of a TurbinePhD system and expects to release the product summer 2012. The system holds U.S. patent number 8082115.

Condition-monitoring systems use sensors to detect component faults, letting maintenance professionals avoid equipment failure. TurbinePhD uses digital signal processing techniques to detect component wear before it escalates into a fault. Smart sensors with embedded processors use algorithms to diagnose problems and then transmit that data to a secure website, where maintenance professionals can see easily-understood turbine health indicators for each component and drill down to view supporting data.

NRG Systems

http://turbinephd.nrgsystems.com/

Filed Under: News, O&M