This article is part of the 2017 Renewable Energy Handbook. A complete digital version of the Handbook is here: https://goo.gl/Sg4mHO

The decision whether to use torque or tension to apply a bolt load is determined by the manufacturer of the turbine and the specific pressure needed. Some manufacturers require the use of tensioning for the entire wind turbine, while others specify torque as the controlled bolting method for tower sections, blades and other turbine areas. Typically, foundation base bolts are tensioned, especially on offshore applications.

With many torque-related tools in the marketplace, there is a growing debate around the proper way to the ensure bolt tightness of wind-turbine components. Increasingly, some say that tensioning and tension-related products should also be considered. The issue stems from variations in the torque and tension specifications supplied by OEMs.

Wind turbines’ bolted joints are typically designed by mechanical engineers, guided by a German-based standard known as VDI 2230, which determines joint stress thresholds.

To properly calibrate torque and tension, and ensure accuracy, installers must apply equations such as those for a tightening factor. The tightening factor is the ratio of maximum tension to minimum tension (Tmax/Tmin) and it reflects the accuracy of the tightening method.

VDI 2230 accounts for the tension scatter or variation from the target value caused by the tightening technique via the tightening factor. Simply put, the higher the tightening factor, the more scatter you get, according to Barnaby Myhrum, applications engineer at Bellows Falls, Vt.-based Applied Bolting Technology. “The more scatter, the larger the bolts needed to increase safety.”

The VDI 2230 standard recommends a tightening factor of 1.6 for torque wrenches. In addition to tightening factors, bolting sequences beyond 11 bolts requires solving for several variables.

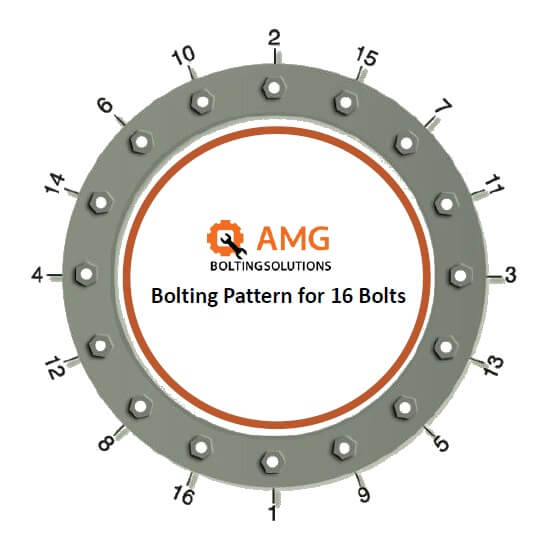

Another company, AMG Bolting Solutions, has created a Bolting Pattern & Sequence Guide to elimination the need to calculate many variables on 12 to 96-bolt applications. Other products, such as direct tension indicators (DTIs), feature lower tightening factors, which can play a crucial role in the dimensioning bolted-joint connections.

Filed Under: Uncategorized