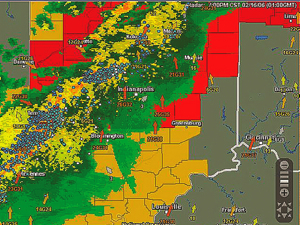

The white triangles show storm corridors that tell wind-farm operators the likely direction of storm activity in their area. These corridors are also color coded to the severity of storm activity, with red being the most severe, yellow severe, and white the least threatening

Don Leick, Telvent, www.telvent.com

When severe weather hits a wind farm, the ultimate safety goal for maintenance crews is to get down from the towers and drive away from the storms. However the height of the turbines and expanse of the properties makes doing so no small task. Therefore, it becomes critically important for wind farm operators to have access to a weather forecast that indicates lightning strikes in real time. Furthermore, the capability to provide alerts to on-site maintenance crews is an effective way to keep wind-farm employees safe. Insight into the practices used by top wind farm power companies can increase operational efficiencies and keep employees safe.

Misguided lightning-safety practices

Wind farms that have on-site maintenance staffs, along with operators, representatives from turbine manufacturers, and contract maintenance crews, typically also have well-established lightning safety practices. Despite the knowledgeable group, they may be laboring under several misguided practices that are not effective and, in fact, can be dangerous.

The first mistake wind-farm personnel can make is reacting only after they see lightning or hear thunder. Lightning can strike miles outside of a storm. Only using one’s senses to monitor lightning activity is dangerous because it will not provide adequate time to respond.

Another practice wind-farm operators should avoid is monitoring radar on a computer or phone and trying to predict whether or not an incoming storm includes lightning. This exposes wind farm operators to two opposite and undesirable risks: false alarms and unidentified lightning in the area.

Lastly, operators who rely on lightning information from free Web sites might not realize that updates from these sites are delayed 30 to 60 minutes. The average life of a thunderstorm cell is 20 minutes, so lightning can be on top of wind farm crews before it shows up on the Web site. With employee safety on the line, it’s worth the price to subscribe to a weather service that provides real-time updates. Wind farm operators who use these unreliable lightning safety practices are gambling with people’s lives. It makes more sense to rely on a real-time lightning detection network combined with immediate alerting capabilities and all-clear notifications as a better way to keep wind farm personnel safe.

Better ways to keep workers safe

To stay on top of changing weather conditions that can endanger employees and impact operations, wind-power professionals need tools to help them launch a preemptive strike against lightning.

Constantly monitoring approaching thunderstorms and tracking lightning activity can be quite a burden to a manufacturing crew. Instead, to effectively track approaching lightning, wind farm personnel should use a real-time weather service that watches the weather for them, and sends alerts directly to mobile phones. Such notification services let them set alerting parameters to meet their particular needs. Determining an alert radius depends on the time it takes to get down from a tower and at least get to the safety of a truck (with windows closed and no one in contact with the metal chassis).

Crews should receive critical alerts before lightning moves into an area. Many wind farms use a heads-up alert to warn crews of approaching lightning. Most wind farms set their alerts to go off when a storm is 50 to 60 miles away. It notifies crews that thunderstorms are approaching the area and they should not begin work that will take them up to the turbine. As lightning gets closer to the wind farm, usually within 30 miles, an evacuation alert should be broadcast. When crews receive this alert, they can suspend work and get to safety before lightning strikes.

Once a storm enters the area, wind-farm operators must determine when operations can return to normal. Figuring out how to get crews back to the field without putting them in harm’s way is a complicated task. While operators want to resume work as quickly as possible, sending crews back to work too early puts them in danger.

A solution is an all-clear alert. It is an effective way of maximizing productivity while ensuring employee safety. A common practice is to send crews back after lightning has not struck within 30 miles for 15 minutes. A few operators take extra caution and wait until lightning has been absent within a radius of 60 miles for 15 minutes.

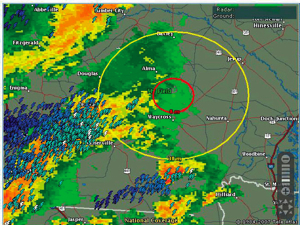

Operators typically set two zones on their site maps: a 30-mi watch zone (yellow circle) and an 8-mi warning zone (red circle). When a storm enters the watch zone, operators must lookout for severe weather. Once a storm enters the warning zone, operators clear the field to ensure crew safety.

In addition to advanced alerting capabilities, wind-farm operators greatly benefit from maps that display real-time lightning data. A visualization of lightning activity combined with radar can provide a good sense of when storms are approaching. This especially holds true when a second line of storms is developing that hasn’t yet entered the warning perimeter. This capability is helpful for maintenance scheduling because operators can avoid starting tasks that will have to be suspended again. Pairing these detailed weather maps with animated lightning strike data shows whether lightning is intensifying or subsiding.

While it is best to have crews responsible for their own safety, centralized monitoring can act as a backup for field personnel who may be preoccupied with maintenance tasks. Personnel at a central facility monitoring weather activity in proximity to wind farms can alert crews about impending weather issues.

Monitoring lightning activity is crucial for maintaining safety on a wind farm, but there is also value in looking back at recent lightning activity in the area. Weather services, such as Telvent DTN MxVision WeatherSentry Online Wind Energy Edition, provides access to detailed data for the previous 72 hours and the opportunity to archive such data for future reference. Details such as time, latitude, and longitude let users quickly pinpoint strikes in the wind farm even when it was overnight or over a weekend. This lets operators document, analyze, and report on lightning activity in the area for damage assessment, analysis, planning, and insurance claims.

This approach is an effective way to keep wind farm maintenance personnel safe. Implementing a complete system of detailed weather is also a cost-effective way to manage crew scheduling and reduce maintenance costs. These systems let wind farm operators mitigate weather disasters, and, better yet, are easy to implement and manage.

How a North Dakota wind farm handles lightning safety

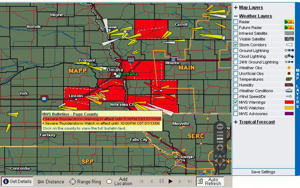

The Omaha area has a tornado alert. Weather for Page County appears in the bulletin feature on MxVision WeatherSentry, which provides NWS warnings. Wind-farm operators can opt to recieve notification of approaching storms on their computer or mobile device.

North Dakota’s flat plains and strong, steady winds make it ideal for a wind farm. But this part of the country is especially susceptible to extreme weather conditions. Summer brings the threat of lightning strikes to the 300-ft tall turbines and brutally cold temperatures are commonplace in winter.

The Langdon Wind Energy Center operates a 40-acre, 133-turbine wind farm in North Dakota. The facility, owned by NextEra Energy Resources, is capable of producing 199.5 MW. To ensure the turbines operate at peak-efficiency, a team of 12 technicians perform routine maintenance duties and are on-call 24/7 in case of an emergency.

“In addition to lightning risks, we don’t send out crews if it’s colder than -28°C,” says Bill Campbell, plant leader for Langdon Wind Energy Center. “In cases of extreme cold, we only send out crews when absolutely necessary.”

To help navigate its weather challenges, the center subscribes to MxVision WeatherSentry Online Wind Energy Edition professional package. By accessing an internet-based platform, the center stays on top of changing weather conditions that endanger operations.

For a complete view of approaching severe weather, the center monitors radar and tracks storms, wind, and lightning on one centralized online dashboard. It features a layered weather map that lets personnel look at the specific weather information most important to its operations. This includes National Weather Service (NWS) warnings, watches, and advisories. Another layer includes custom areas of maximum impact based on parameters set by the center to reflect how weather is affecting the exact location of its turbines.

In addition to the online dashboard, the Center uses a mobile alerting system to view current and future conditions. To stay one step ahead of the weather, employees also have access to all of the online dashboard’s weather information on their mobile phone. Personalized alerts are sent instantly to employees’ phones when severe weather nears user-defined alerting parameters. This is especially important for field technicians performing maintenance tasks.

“We let the technicians know when lightning has been detected within 60 miles,” says Campbell. “When lightning is detected within 30 miles, we require our crews to evacuate the turbines.”

The mobile alerts are fed from an alert manager that provides instant notification of significant weather changes within their coverage area. When weather conditions such as wind-speed change or when the NWS issues a watch, warning, or advisory, an audible alarm is triggered through the online dashboard. “The system alerts us by sounding a siren that lets us know we need to either monitor weather conditions more closely or evacuate crews,” says Campbell.

Red areas are counties under a National Weather Service severe weather warning. Yellow indicates a watch area. The map lets users zoom in on weather conditions to find exact location or out to monitor storms heading towards their operations.

The most critical weather component for the center is the Lightning Manager. Receiving advanced warning of real-time lightning strikes from real-time lightning data is much safer than predictions that can lead to false alarms or delayed reporting after lightning has already struck.

Five Langdon crew members use the system. They can access weather data in the office, on the wind farm, and at their homes. “If my guys get called in over a weekend, I can log on from home to find out what’s going on with the weather and ensure their safety,” says Campbell.

In addition to watching storms as they pass through the area, Campbell and his technicians use hourly and 10-day forecasts to schedule routine maintenance. This allows for more efficient planning. For example, a wind turbine should not be slated for cleaning with a rain storm impending.

Although this type of renewable energy relies on the wind to generate electricity, too much wind can also impact operations and safety. If winds are too strong, crews cannot work on the turbine’s hub. Although each turbine has a wind speed indicator, Langdon Wind Energy Center also ensures safety by relying on monitoring systems for wind speed and direction.

As a result of implementing an advanced weather information service, Campbell and his technicians have been able to improve operational efficiencies while securing a high level of safety. “Safety is a shared value at our company,” says Campbell. “We rely heavily on real-time weather information to keep our technicians safe and operations running efficiently.”

Filed Under: Safety