Dr. Ashley Crowther / VP Engineering / Romax Technology / www.romaxtech.com

As gearboxes age, planet-bearing failure from rolling contact fatigue become an issue for maintenance budgets.

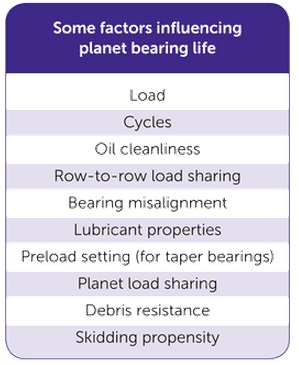

Many factors influence bearing life but load and cycles are required for failure. After a sufficient number of rotations, the bearing will fail from fatigue. And the higher the load, the sooner it fails. Other factors that accelerate the process include poor row-to-row load sharing, poor oil condition (such as high water content, debris, additive depletion) and skidding. To make matters worse, the main gearbox must be relatively light weight to reduce the capital cost of wind turbines. A heavier gearbox means a larger tower-top mass, which affects the size of all supporting components, such as the bedframe, yaw bearing, tower, and foundation.

The size of the planetary stage in the common gearbox architecture is the principal factor in its overall weight. To control the gearbox weight, the sun gear, planet gears, and planet bearings then must be sized close to the margins of calculated design life.

The size of the planetary stage in the common gearbox architecture is the principal factor in its overall weight. To control the gearbox weight, the sun gear, planet gears, and planet bearings then must be sized close to the margins of calculated design life.

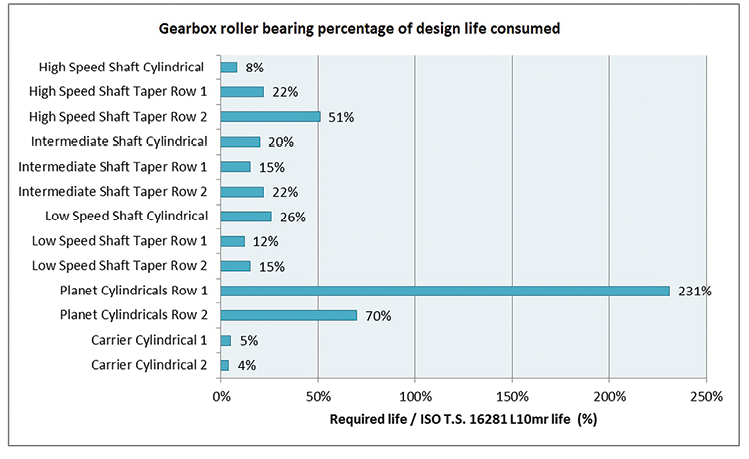

The bar chart, Gearbox roller bearing percentage of design life consumed, provides examples of bearing life used up in one particular gearbox over its 20-year design load spectrum. 100% design life consumed means that bearings in that position would have a 10% chance of failure over the 20-year required life, which is the limit required by certification bodies and in standards. The results in the graph were found using the latest calculation methods including predictions of the load sharing between and misalignment of all components. While the original design met the simpler design calculations required at the time, the factors shows that Row 1 of the planet cylindrical bearings do not meet the design requirement and will have a much higher failure rate than anticipated.

The chart is for an old design which has since been re-engineered by Romax, to be improved within design constraints. Many modern gearboxes have better life ratings than this example, but the planet bearings are commonly the bearings that undergo the heaviest fatigue loading. They are commonly the critical component for sizing the planetary stage.

The chart is for an old design which has since been re-engineered by Romax, to be improved within design constraints. Many modern gearboxes have better life ratings than this example, but the planet bearings are commonly the bearings that undergo the heaviest fatigue loading. They are commonly the critical component for sizing the planetary stage.

Portable vibration systems, such as this one from Romax, provide a solution for sites that can’t invest in permanent condition monitoring hardware.

So should we build heavier gearboxes? Mandated higher safety factors would increase life at the cost of heavier gearboxes. This is worth examining on a levelized cost of energy versus competing power generation industries. Would the increased capital cost be more or less than the maintenance cost?

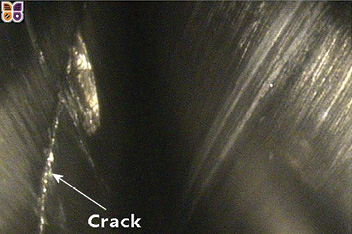

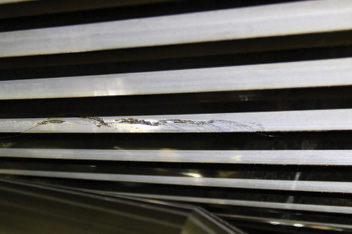

Certainly a lot of issues have been resolved in gearbox design and improvements made, such as the avoidance of spherical roller bearings which caused serial failures in earlier gearbox designs. Typical drivetrain problems from the last few years appear in Generic wind turbine drivetrain layout and common problems along with related photographs. Failures are generally driven by more than one issue, a few of which include steel quality, grinding inaccuracy, assembly damage, incorrect assembly, transportation damage, and residual tensile stresses. As a drivetrain population works through its batch related and early failure issues, fatigue related failures may start to dominate, and then planet-bearing failure rears its ugly head.

Mitigating costs with a structured effort as a wind farm ages is important because some frequency of planet-bearing failure is inevitable. Start with these costs: production downtime, replacement gearbox cost, labor cost, crane costs and mitigation cost, then ask: What strategy provides the best long term result for the balance sheet? The right strategy for one farm is not necessarily the same for another.

Generic wind turbine drivetrain layout and its common problems

What is the failure rate? Do you expect three failures a year or one every two years? Reliability analysis can use wind farm failure data to reasonably forecast these rates. Or, Romax can advise based on turbine makes and models and site characteristics. Then a best practice can be established for that wind farm based on cost optimization. Detection tools include filter (or swarf sensor) inspections, oil-debris monitoring, temperature monitoring, borescope inspections, and vibration monitoring. Time to failure (prognosis) can be estimated with semi-analytical modeling and empirical models, a challenging area and not solved by “catch-all” mathematical models. Failure rates can be slowed with cleaner oil, better oil, turbine de-rating, and (although challenging for an owner to implement) controls-based loads mitigation.

What is the failure rate? Do you expect three failures a year or one every two years? Reliability analysis can use wind farm failure data to reasonably forecast these rates. Or, Romax can advise based on turbine makes and models and site characteristics. Then a best practice can be established for that wind farm based on cost optimization. Detection tools include filter (or swarf sensor) inspections, oil-debris monitoring, temperature monitoring, borescope inspections, and vibration monitoring. Time to failure (prognosis) can be estimated with semi-analytical modeling and empirical models, a challenging area and not solved by “catch-all” mathematical models. Failure rates can be slowed with cleaner oil, better oil, turbine de-rating, and (although challenging for an owner to implement) controls-based loads mitigation.

Detecting and monitoring impending repairs

Romax uses its Fleet Monitor software, a web-based platform for monitoring turbine health. This software platform lets condition-monitoring engineers keep an eye on a global fleet of turbines, regardless of their type or the CMS used. The software brings in the data for monitoring and failure forecasting. Data comes from CMS hardware, SCADA systems, maintenance systems, oil labs, and inspection reports. The system provides powerful capabilities to optimize asset management.

Romax uses its Fleet Monitor software, a web-based platform for monitoring turbine health. This software platform lets condition-monitoring engineers keep an eye on a global fleet of turbines, regardless of their type or the CMS used. The software brings in the data for monitoring and failure forecasting. Data comes from CMS hardware, SCADA systems, maintenance systems, oil labs, and inspection reports. The system provides powerful capabilities to optimize asset management.

Consistent alarm strategies can be applied so that lessons learned on one farm are quickly and efficiently

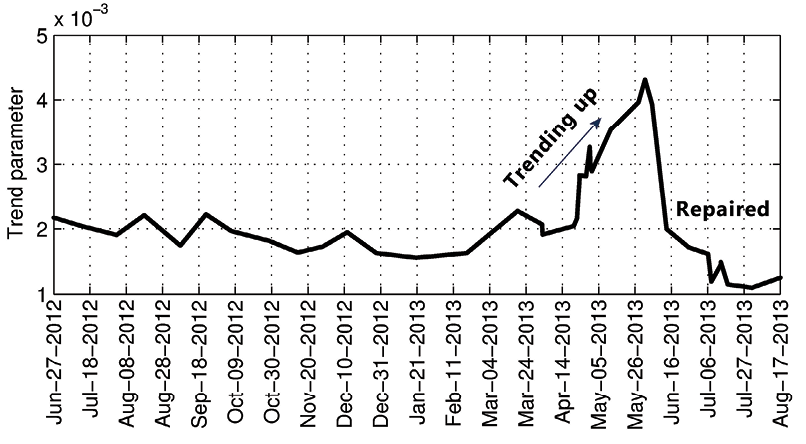

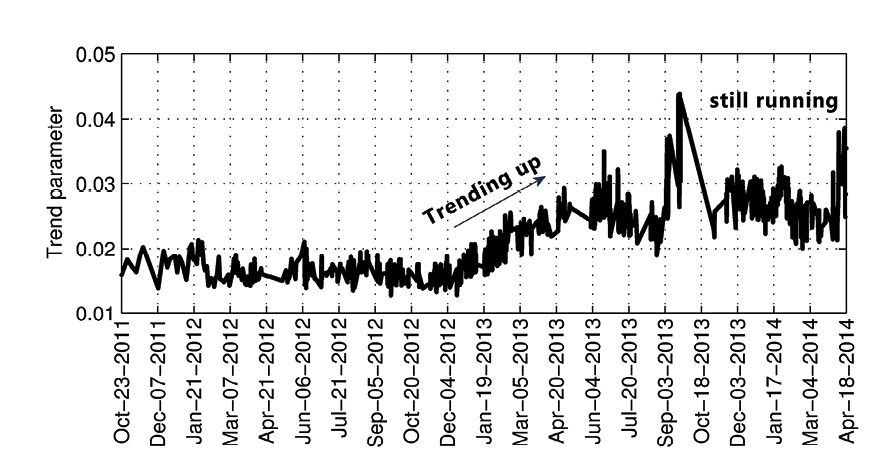

The upper graph is for a gearbox repaired with months of pre-warning. The lower graph is from a gearbox that is still running as a repair is scheduled along with others requiring the large crane. In both cases downtime was minimized.

implemented to improve the monitoring quality on another, without the difficulties created by moving between disparate systems.

For wind farms without the budget for permanent CMS, portable vibration data acquisition equipment is also available. This type of equipment is not new; industrial computers with data acquisition have been used for decades. However, wind industry version must be highly reliable, easy for wind-farm technicians to use, configured specifically for wind turbines, and robust for use in the nacelle. A lot can be done to assess the health of a machine with up to 8 channels of acceleration, a current transformer for power measurement, speed sensor, 3G connectivity (for accessing the data remotely) and a user interface for various aspects of configuration and turbine input. Our company is analyzing hundreds of turbines annually with this equipment.

Many factors govern the reliability issues that must be managed at each wind farm, and each site certainly has different problems. Planet-bearing failures (in modern gearbox designs) generally don’t occur until gearboxes are five years and older.

Many factors govern the reliability issues that must be managed at each wind farm, and each site certainly has different problems. Planet-bearing failures (in modern gearbox designs) generally don’t occur until gearboxes are five years and older.

InSight Fleet Monitor, web-based software, interfaces with permanently installed condition-monitoring hardware.

For this one example, a certain set of activities offered by Romax InSight can be tailored for mitigating the costs, for example, by monitoring, drivetrain inspections, time-to-failure prognosis, improved scheduling, and oil-system improvements. Yet one size does not fit all. Even adjacent wind farms with the same turbine models can have a different run of problems (or lack of). Combining the most effective activities in a tailored approach, as suggested in the table, can maximize O&M cost reductions and financial benefit. WPE

Filed Under: Bearings, Gearboxes, News, O&M