Lubrication routines in wind turbines are costly and time consuming, especially in extreme climates.

So it’s no surprise that poor lubrication and maintenance can cause gearbox failures. Even before failures, not having an efficient grease hinders energy production and shortens turbine life.

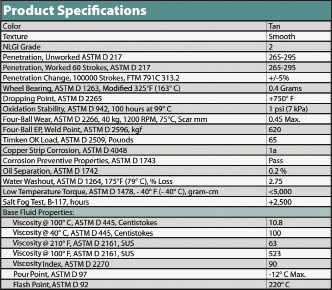

One company says its nanoceramic grease lasts 10-times longer than traditional PTFE greases to meet wind turbine demands. Dayton Progress (www.daytonprogress.com) adds that its DAYLube grease maintains its viscosity and has a much lower coefficient of friction than other greases at all temperatures. The thick grease is best suited for bearings, bushings, cables, cams, chains, gears, lifters, machine parts, and slides.

“Extending a maintenance interval is always favorable,” said Bob Hedrick, Dayton Progress Marketing Manager, “but, it is especially important when the maintenance takes place in difficult to reach locations such as wind turbines. Here, the extended up-time means fewer trips into hard to reach areas and less time scaling ladders or lifts, which can improve safety and employee morale.”

The grease has survived the ASTM 4-Ball Weld Test, which begins with three ball bearings submerged in grease. Then, 500 kg is applied to the center ball bearing, which is spun at 10,000 rpm for ten seconds. To pass, it should survive with “no weld.” The grease received a passing grade and performed well, with only minimal damage to the ball bearings. This is in sharp contrast to competitive greases which, when subjected to the same parameters, suffered a soft weld within two seconds. Complete failure followed with major damage to all four bearings.

The company says nanoceramic particles in its grease act as sub-microscopic ball bearings. These are placed over a calcium sulfonate thickener within a mid-viscosity, petroleum-based paste. The particles have a natural attraction to steel and provide continuous lubrication at the surface.

“Users have reported significantly longer service life – up to 10-times longer – than traditional PTFE lubricants,” says Hedrick. “Also, compared to other greases, it has a lower cost per ounce, which makes it cost effective in wind turbines.”

Chemically inert and environmentally friendly, the grease is suitable for use in sensitive environments. Hedrick says the strong adhesion extends production because it does not soften or run out. After 100,000 production strokes in another test, it shows no evidence of breaking down.

The grease is NSF-H1 Food Grade Certified for temperature ranges from -40 to 800°F – and the nanoceramic particles remain intact to 2,500°F.

Filed Under: Lubricants, News

Ball bearings play a vital work in fan. For lubrication, grease or oil is used. In vehicle we want o use small amount of grease but the CPU fan is rarely require to fill oil.