Tribco Inc. will exhibit brake pads that last 3 to 5 times longer than conventional brake pads—but won’t scratch or wear down brake rotors—because they are lined with Braketex, the world’s first and only 100% Kevlar fibered composite friction lining.

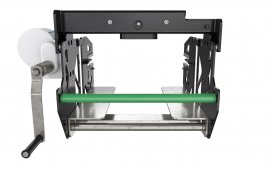

Wind turbine brake pads

Braketex is also virtually dust free whereas conventional linings generate dirty, abrasive black dust that contaminates lubricants and damages electronics and other critical components. Additionally, Braketex is environmentally friendly because it does not contain asbestos or other harmful ingredients.

Braketex-lined brake pads are ideal for wind turbine mechanical and yaw brakes—and help reduce maintenance downtime and expense while increasing turbine, reliability, up-time and output.

Tribco stocks replacement brake pads and clutch plates for many applications and will also custom fabricate new parts to order or reline used metal plates and carriers.

Overall, Tribco’s exclusive 100% KEVLAR fibered composite friction lining has been performance proven in thousands of dry and wet brake, clutch, PTO, power transmission, torque converter, synchronizer and other friction applications worldwide for over 25 years.

This includes aerospace, agriculture, aviation, construction, defense, forestry, manufacturing, marine, material handling, metal forming and stamping, mining, oil, packaging, paper, printing and trucking industry applications to name a few.

Filed Under: Pitch & yaw