A new concept for a concrete-jacket foundation with a hundred-year minimum life is intended for wind farms headed to the deep water of the U.S. continental shelf. The design is sufficiently durable and scalable to support four consecutive generations of direct-drive wind turbines rated at seven megawatts and more.

Andy Filak / Principal / AMF Concepts

The expansion of offshore wind power is inevitable and growing due to the ready supply of high-quality wind and the elimination of many onshore objections. To date, one of the major hurdles has been the development of reliable foundation systems with long life and ease of installation in deep water.

Today’s concrete technology is not sufficiently robust for the long-term exposure experienced in an ocean wind farm. In addition, steel technologies require complicated shore-side construction and at-sea installation procedures with multiple large-crane barges and anchor-handling tugs.

A recent advance in composite concrete (geopolymer cement) intended for marine use and a new catamaran Ocean Going Deck Barge (OGBD) solves both of these issues. Three breakthroughs make long term, offshore-jacket foundation possible.

- The first omits the Ordinary Portland Cement (OPC) binder in the concrete.

- The second replaces the coated-steel rebar with a non-metallic material that will provide a reinforced structural frame.

- The third launches the jacket foundation in a completely novel way. The combination of these advances will increase the longevity of the jacket system while simultaneously reducing construction, installation and maintenance costs.

Introduction

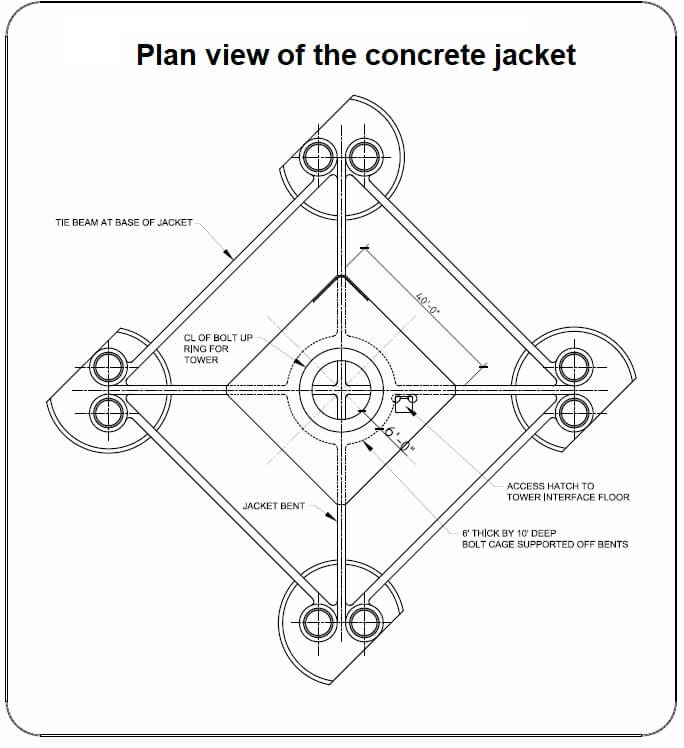

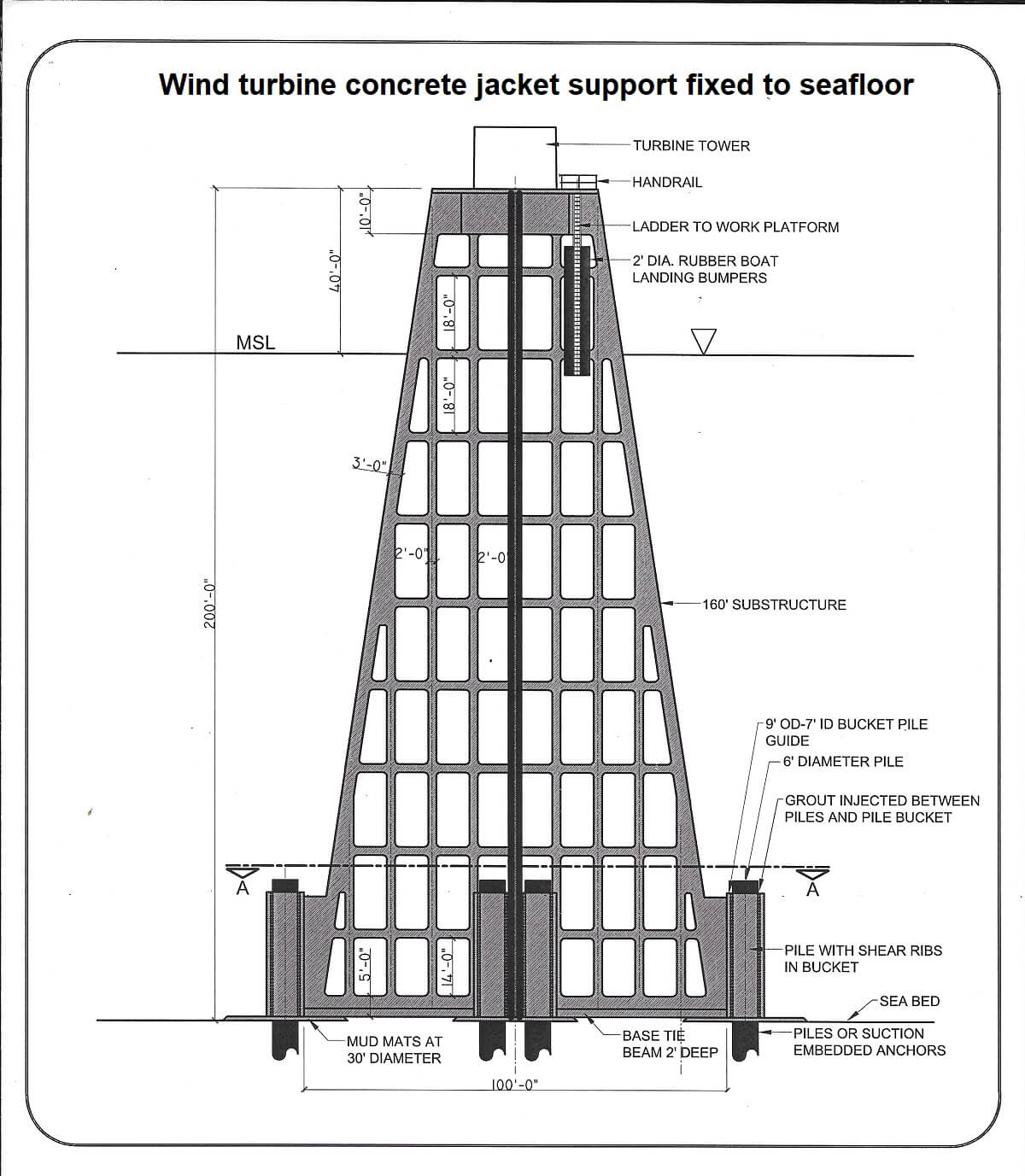

A side view of the proposed 200-ft tall concrete jacket shows the MSL or mean sea level and the possible anchoring methods. About 160 ft of the structure would be submerged. Pick on all images here for larger versions.

The beauty of deep offshore wind is that it consumes no real estate and blocks no views while harvesting steadier and more predictable wind. This condition allows for the use of large direct-drive turbines. This article will describe a new foundation system for these turbines.

Its new construction and deployment processes allow erecting a wind turbine for a fraction of the current foundation cost in deep water. Our concept will have a lower installation cost due to the way it is produced and deployed. Our jacket is constructed on an Ocean-Going Deck Barge (OGDB) while tied to the quay. The barge is then released and powered out by its own propulsion to the wind farm for deployment.

Material improvements

The revolution in materials is the basis of this exciting new technology. In existing marine concrete structures, the greatest threat is water, either fresh or salt. Through time, water penetrates into concrete through unseen cracks and material porosity, and rusts the rebar skeleton. Even proactive rebar has coating failures and deterioration which eventually allows the steel failure. Seawater also directly attacks the chemistry of Ordinary Portland Cement (OPC) causing rapid failure.

What causes the OPC binder to fail at sea is the high percentage of calcium compounds (about 70%) that come under attack by the sulfur compounds in seawater. This rots the concrete. The binder in a concrete mix can occupy up to 20% of the mass of the concrete. Replacing the OPC cement binder in the concrete mix design with a geopolymer binder foils this degradation scenario by minimizing the calcium compounds in its composition.

The geopolymer cement binder is made of four inexpensive and widely available components:

- Type-F fly ash,

- Freshwater,

- Water glass (sodium silicate), and

- Lye (sodium hydroxide).

With the type-F low calcium fly ash, the binder can have as little as 2% calcium, producing a salt-resistant material.

Geopolymer cement binders are used commercially elsewhere in the world due to their superior performance over OPC binders. In general, these cements are stronger, fireproof, and waterproof. They also bond well to most materials, have minimal expansion or contraction, and are resistant to salt, acids, and alkalis. Another plus: The production process for geopolymers has about 80% smaller carbon footprint than standard OPC.

To replace the rust-prone steel rebar, a nonmetallic bar made from readily available basalt is used for reinforcement. Basalt stone, found all over the earth, is a key component enabling the hundred-year durability of the jacket structure. Heating basalt stone to 1,800°F liquefies it so it can be run through a palladium die to produce soft flexible fibers or threads. The threads are laid in parallel and locked together with an epoxy, producing basalt rebar: a waterproof, chemical resistant, fireproof material with a tensile strength several times stronger than steel. (701,000 psi for Basalt Bar vs 60,000 psi for steel)

Kodiak Fiberglass Rebar manufacturers basalt rebar in the U.S. The company says it’s occasionally referred to as Basalt rock rebar, Rock Rebar or BFRP rebar. The material has about one-fourth the density of steel.

The geopolymer binder in the concrete binds to the basalt rebar on a chemical level in addition to the mechanical bond. The basalt bar is extremely light and fairly flexible, making it easy to place in the structure. Cut basalt fiber additives, much like nylon fibers, would add strength to the mix. The jacket substructure, made of the geopolymer binder in the concrete mix, will have a minimum 100-year life due to the low porosity, high strength, and heat-cure technology.

Forming the foundation substructure

The conventional construction and deployment of a steel-jacket foundation (which could stand 200-ft high and weigh1,000 tons) would be fabricated in a quay-side yard and lifted with a heavy lift crane onto an OGDB for a tow out with tugs. These tugs also act as anchor handling tugs for final positioning the jacket in the wind farm. A high capacity crane vessel is then required to place the jacket in the wind farm. All these vessels spend long periods in open water and are significantly affected by ambient sea states. But an alternative to this construction and deployment can substantially reduce the port-to-site cost and time.

To develop a concrete jacket, a wide variety of formwork systems used around the world were studied. All but one was dismissed as unable to improve overall “Port to Site” time and cost. The only method to show significant promise in reducing timelines (a four-day build out) and cost was Slip Forming. This formwork system produced the most cost-effective solution with a heat-cured formwork that can achieve a two feet per hour slip. This allows completing a jacket in under four days and at a saving of 350 crew hours. Slipping the jacket uses standard methods except for the heated formwork and the trunk placement of the geopolymer concrete (This mix cannot be pumped because that generates friction heat.) The jacket, slip formed as a seamless concrete structure, will have its steel jack rods extracted at the end of the slip, producing a steel-free concrete structure.

Ocean-going deck barge

The cost to slip form the jacket on land and lift it onto an OGDB is uneconomical. Therefore, it is necessary to develop a self-propelled catamaran OGDB. To simplify the overall process, the OGDB serves as a construction platform, transport vessel, and deployment platform all in one. The jackets are slip formed at each end of the barge while it is moored to the quay and with ready access to materials and resources. Upon completion of two jacket substructures, the barge is powered out by its own propulsion to the windfarm site with both jackets onboard. At the site, the barge’s dynamic positioning system positions the jacket over the pre-pile center and lowers it with its active heave compensation (ac) linear winches over the piles to the seabed where it will be leveled and grouted.

The catamaran barge measures 420-ft long, 200-ft wide, and a 27-ft deep. This, less the deck-well cuts fore and aft, provides 52,100 ft2 of deck area. The weight of the barge per square foot, including extra hardpoint structural framing, ballast system pumps, and piping, is estimated at 600 lbs/ft2, for a total of 15,600 short tons. With a foot of draft displacing 1,344 short tons, the unloaded barge will have a draft of 11.6 feet.

An estimated deck load (without jacket loads) adds 1,200 short tons. Prior to jacket production, ballast tanks will be filled with 4,400 short tons of water at the quay, bringing the total draft to 14.9 ft. The total weight before production at the quay is 21,200 short tons.

During the two-and-a-half-day slip, the ballast management system will pump out the equivalent weight of the placed concrete as it occurs to maintain a steady draft and level deck surface. During the power out from the quay, with both jackets complete and in place, the OGDB draft will remain 15.8 feet, with a power out freeboard of 11.2 feet.

The inboard sides of each catamaran hull holds two, hydraulically lifted, construction-support platforms (total of four) two each in the fore and aft wells. These platforms support the slip-form-starter section, as well as the construction weight of the jackets in each of the well cuts. These construction support platforms stay in place until the jacket placed in the water.

Dynamic positioning and control

Critical to a safe and efficient operation, the OGDB is equipped with two azimuth propulsion units (one on each hull) And two bow thrusters (one on each hull) controlled by a dynamic positioning system to position and hold the OGDB as the jackets are deployed. The dynamic positioning will have active wind and current compensation, thruster selection and enabling, power management, automatic heading hold, and other pertinent sensors. All the information sensors, data readout, video feeds, and manual and joystick controls for the entire OGDB will be housed and displayed on the control console of the third level of the superstructure.

Deploying the jackets

There are two methods of installing the piles for the jackets: Pre-piling and post-piling. In pre-piling, a center template secures the position on the seabed. In post-piling, soil piles are driven inside the jackets’ pile sleeves (buckets) using a subsea vibratory hammer. Sea-bed leveling of the jacket can be accomplished by varying the pile sticks-up. This makes it easy to adjust the vertically of the jacket. Because of the cement binder in the grout concrete, the pile bucket has a chemical and mechanical bond so only sheer ribs are needed on the pile.

Upon arriving at the installation site, the jacket would be deployed in two stages. The total weight of the jacket, depending on design, will require four Strand Jacks (linear winches with active heave compensation (ac) ) to lower it into the water. Each linear jack is rated at 731 short tons with a 2.5 minimum safety factor. All are operated simultaneously from a single computer. Furthermore, all are attached to Dyneema tendons that are proven to have a long life in salt water. The tendons, in turn, attach to steel jacking strands that do not enter the water. There are 43 steel jacking strands in a bundle (weighing in at 45 lbs/ft) going through the jack. To keep the bundle tensioned, a synthetic rope is attached to a tensioning winch.

During the first-stage lowering operation, the water ballast management system again controls the deck leveling, in direct reverse to the construction phase. The second-stage lowering is completed after the dynamic positioning over the pre-driven piling is complete. This is accomplished with target sensors and video feeds. The jacket is then leveled and grouted.

Construction costs

This opinion, with accurate input, identifies the unit cost at $4.8 million per jacket (excluding the cost of the piling and wind turbine). Construction and installation costs are a fraction of the current steel-jacket cost because there is no need for tow-out tugs, anchor-handling tugs, or heavy lift crane vessels. Additional details are available upon request.

Reach Mr. Filak at amfconcepts@gmail.com , 310-373-5004

Filed Under: Offshore wind