C-Motives C-Machine Capacitive Machine is an electrostatic motor designed as a full replacement for existing motors and generators

A tabletop motor using an entirely new driving principle is under development at the headquarters of C-Motive Technologies, a startup business that is commercializing technology from the College of Engineering at UW-Madison.

“We have proven the concept of a new motor that uses electric fields rather than magnetic fields to transform electricity into a rotary force,” says company co-founder Dan Ludois, an assistant professor of electrical and computer engineering at the UW. The distinction may sound minor, but it could solve a number of practical problems while saving money, he explains.

Actually, the concept is not entirely new: Benjamin Franklin and others described and built motors based on electrostatic forces back in the 18th and 19th centuries, but none achieved practical operation. Since the widespread adoption of electric motors a century ago, magnetism has been the only practical source of rotation. Magnetism is easier to exploit than electrostatic fields due to the properties of naturally occurring materials and simple engineering techniques. However, new advances in materials, mechanical engineering and advanced manufacturing may enable electrostatic motors.

In 2011, while Ludois was finishing a Ph.D. thesis at UW-Madison, he realized that instead of relying on magnetic fields, he could achieve a similar result by manipulating electric fields to create a motor based on electrostatic attraction. The new technique, he realized, could deliver major advantages in weight, material cost, operating efficiency and maintenance requirements.

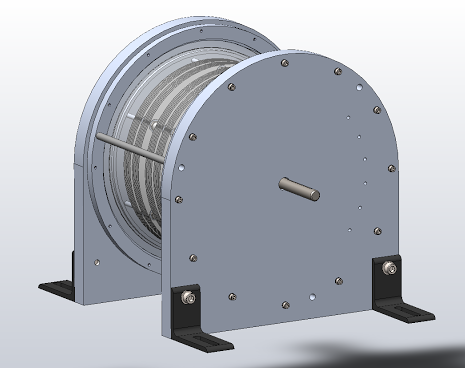

In the motor on display, nested stationary and rotating plates are held hairs-width apart by a unique air-cushioning strategy. An electric voltage delivered to the fixed plates creates an electrostatic field that attracts the rotating plates in a way that forces them to spin.

“A charge builds up on the surfaces of the plates, and if you can manipulate the charge, you can convert electricity into rotary motion or transfer electric power from one set of plates to the other,” says Ludois.

This type of coupling can be used “to power things that move without touching,” Ludois adds.

The breakthrough relies on electronics that precisely control a high-voltage, high-frequency electric field and fluid mechanics to keep the surfaces close without touching. “Nothing is touching, because you are using electric fields to couple the stationary and rotating parts,” Ludois says. “There is no contact, and no maintenance.

Because motors and generators are essentially mirror images of each other, the invention may first meet the market in the form of a generator for wind turbines, an application for which C-Motive Technologies received a Small Business Innovation Research grant for development and research from the National Science Foundation in 2014.

By saving weight and materials, and boosting efficiency, the new design should give the company a bottom-line advantage. The new design avoids the use of precious “rare earth” metals and substitutes aluminum for the more expensive copper found in magnet windings of conventional motors and generators.

When C-Motive was founded, Ludois and co-founders Justin Reed and Micah Erickson were all Ph.D. students. “It’s really hard to beat the world, especially when you start out as three graduate students,” Ludois says.

C-Motive has had its share of help from UW-Madison. Two years ago, the idea won two awards in the G. Steven Burrill Business Plan Competition, run through the Wisconsin School of Business. C-Motive has also received $100,000 in seed funding from the Weinert Applied Ventures in Entrepreneurship course, another School of Business resource.

University of Wisconsin, Madison

www.engr.wisc.edu

C-Motive

www.c-motive.com

Filed Under: Generators, News, Turbines