This article comes from a recent issue of the ABB Review, Integrating Renewables

Adiran Timbus, ABB Power Systems, Power Generation Zurich, Switzerland, adrian.timbus@ch.abb.com

Throughout time one of man’s greatest aspirations has been harnessing the power of the wind. However, capturing this raw energy and transforming it into another energy form has always been a significant challenge. The modern day example is wind turbines and the utilization of wind energy to generate electrical power. Effective optimization of wind farms and independent wind turbines requires innovative, leading-edge control technologies. Through better monitoring and control ABB’s automation system Symphony Plus for Wind is increasing the value of wind energy.

As the power industry moves away from subsidized markets based upon feed-in tariffs and toward greater participation in the wholesale energy market and long-term power purchase agreements, today’s technologies must enhance wind power generation within the competitive marketplace for renewable energy.

To do this, new technology is needed to facilitate optimized grid integration by improving the performance and reliability of wind turbine operation, reducing the cost of generation, and by improving production forecasting and power production management throughout the life cycle of a wind farm.

Understanding the harsh environmental conditions in which wind turbines operate and the overwhelming demands placed on wind-farm operators is paramount to achieving the desired levels of improvement. Consequently, modern control systems and new sensing devices must be developed to meet the specific and exacting requirements of the wind-farm operators.

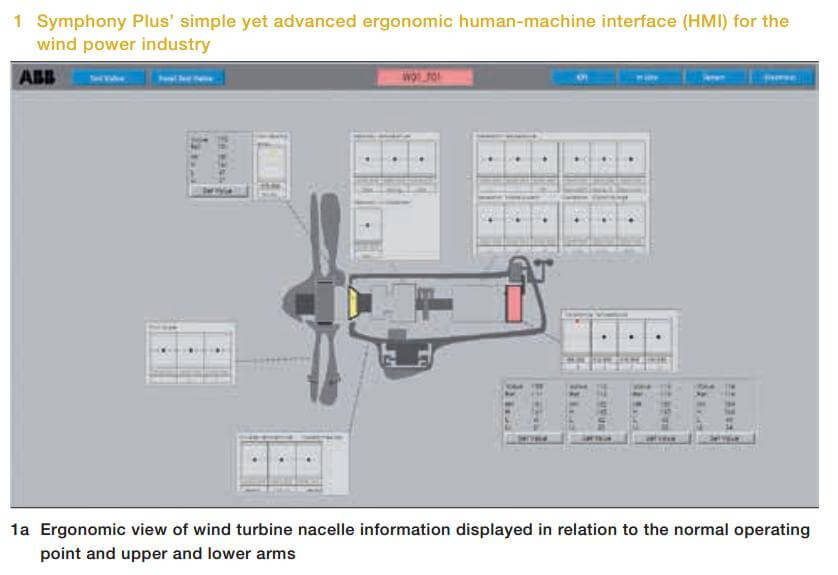

Automation control must have an intuitive human-machine interface (HMI), providing operators with timely access to the actual operating parameters and production data that will be used to ensure wind-farm production is optimized.

Market requirements: Using extensive experience gained from the successful operation of conventional power plants, ABB automation control systems can be harmonized for the optimized production from wind farms. The same supply challenges of flexibility and security of supply must be overcome. By ensuring that power quality is maintained through proper control systems, power production can be accurately forecasted and planned, and a power output to match system demand can be provided.

Grid codes: Electricity generators are required to comply with the stringent requirements of the network codes respective to each country of operation. These codes, also known as grid codes, specify the technical conditions and processes required for a generator’s compliance with all aspects of planning, connection and operation. The essential requirement of grid codes is to ensure wind power plants behave in a similar way to conventional power plants and provide the necessary grid support functions.

Modern control systems and new technologies have to support the challenges associated with grid integration and the contrasting variables in operating parameters required for grid-code compliance worldwide.

Beyond grid codes: ABB’s automation system for the wind industry, Symphony Plus for Wind, has been configured to provide the control functionality required for grid-code compliance using bespoke control libraries implemented in a high-performance controller. This latest technology provides frequency containment by modulating active power and steady-state voltage control by changing reactive power. Importantly, by treating the wind farm as an integrated power plant, substation influence is also included in the system.

An optimized control system considers the capacity of each turbine to produce reactive power; checks the level of reactive power at the substation level; interfaces with the tap changer of the main transformers to help regulate the voltage inside the wind farm; considers the voltage levels within the wind farm collector grid; and controls the reactive power resources to minimize losses in the collector grid to maintain voltage levels within the constraints. Managing voltage and reactive power inside the wind farm reduces tripping risks and losses in the collector grids.

Read the rest here: https://goo.gl/y94b1y

Filed Under: News, O&M