A novel turbine design uses two rotors of equal diameter, one each at opposite ends of a nacelle, to capture wind at greater capacity factors than conventional designs can do, say developer Airgenesis LLC (airgenesiswind.com). The developer says the rotors, offset from each other by 60°, will be turning at low speeds of 2.5 to 3.3 rpm, and are capable of producing 51 kW in wind speeds of about 5 mph. With a maximum of 3.3 rpm, it minimizes the possibility of harming wildlife. The low speeds also minimize the danger of ice throws. “All the high rpm speeds are inside the turbine,” explains company spokesman Clayton Troxell. At a wind speed of 15 mph, the design will be producing over 1 MW with a maximum possible output of 10.7 MW at 32 mph. The design has passed engineering proof of concept and is ready for licensing. Plans are already in the works to build and test a 10.7-MW unit by next year.

The Airgenesis design uses two rotors, one at each end of a nacelle. Gearboxes and generators mount at ground level for easier access.

There is more to the new design than two rotors. “Most of the heavy equipment is mounted at the base of the turbine so maintenance work can be simplified. Furthermore, using multiple generators provides the capability of replacing generators without shutting down the turbine. Clipper Windpower uses a design of four generators for similar advantages but mounts them in the nacelle. Troxell says many details covered by several patents are being held confidential. The design is said to target a constant electrical output at low wind speeds, conditions in which traditional wind turbines cannot operate.

The company did reveal details of the design to power-plant maintenance expert Jerry D. Casteel who then commented, “Placing components that are costly to maintain to the ground will make the Airgenesis design competitive with fossil fuel and hydro units of the same size.”

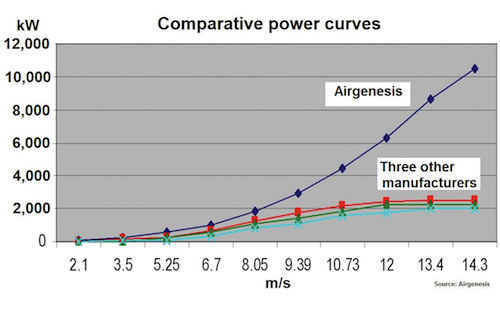

The plot from Airgenesis is said to illustrate the potential advantage of its design over conventional wind turbines.

The company says it is confident the design represents 80% more efficiency than most conventional commercial systems, three times the megawatt production of current ground technology, increased energy to grid, reduced tonnage and stress loads on towers, and complete construction costs of less than $400,000 per MW when in full production along with overall reduced operational costs.

WPE

Filed Under: Components, Nacelle, Turbines

It’s a bunch of nonsense. Idiotic thinking of how to add power output on the same “tower”. So they put another set of blades on the back. This is a horrible idea and has no physics support or logic behind it. The back blade will create drag on the front blade while spinning because the airflow is going to be broken as it moves.

Dear Sirs:

It is difficult for me to understand why, even when a person with a good idea regarding an extremely important subject such as the alternative energies, it is hard to find someone willing to invest some money on this. No great amounts are needed to realize this project, so it’s difficult for me to understand why no one is willing to try. Do not think only about wind, sun, water, please consider also these projects that do not need these elements. With the mechanism in the video I am confident to reproduce an unbalanced continuous movement. This device could revolution the way to produce energy. But financing is needed to finish it. Why don’t we try to create this prototype?

Michele Stragà

If you are interested in,please contact me. An introduction to the idea is available at:

http://www.youtube.com/watch?v=k2qXEFDRW50

Mr. Straga:

I watched the video but I don’t quite understand the invention. I would suggest building a working model and then look for investors.

Best of luck.

Paul Dvorak

It looks like the only thing the developers can be trusted with is computer illustration packages.

I can understand that a new company would develop a design and get approval (a sort of sanity check) from recognized authorities such as NREL and maintenance consultants. The idea has merit. The company says it will build a prototype next year. Lets see what happens.

Paul

@ Michael M. Your assumption that conventional wind turbines maintain a cp of 0.4 at higher wind speeds is off base. At higher wind speeds the power coefficient of traditional turbines drops rapidly as the turbine approaches maximum rpm. According to this article the airgenesis design can utilize multiple generators allowing their equipment to maintain a constant cp of 0.45, well below the maximum illustrated under Betz’s law. This allows for much better performance at higher wind velocities.

Michael:

You have a worthy comment.

However lets consider that the two, three blade rotors are a significant distance apart so that the interference between them is small.

Would that not actually be like two separate wind turbines with each contributing their separate wind energy capture? I will bet you “Two Betz” that the Airgenes idea is something better than one rotor.

If I were Airgeneses I would join hands with Yuji Ohya at Kiyushu University in Japan and revolutionize the design of wind turbines; I think both ideas are winners!!

Please collaborate….patent litigation stifles progress. Making 50% of a big discovery beats the hell out of not sharing ideas.

Paul V. Preminger

For some time now, I have been suggesting fixing a ring around the ends of the blades to improve stability and thereby gain more efficiency.

By using a “wind lens” for the fixed ring as suggested by Yuji Ohya (Kiyushu University) on each set of three blades mounted on each end of the nacelle (the Airgeneses design), the combination should really produce a Power House!

My associates and I have designed a 200 metre high cast in place post tensioned concrete tower for horizontal and vertical axis wind turbines. The total installed cost of our 200 metre high concrete tower is almost the same as the cost of 100 metre high steel towers when the steel,transport from point of fabrication, access road improvements, elimination of large cranes, etc. are taken into consideration. The greater wind energy capture from the better wind regimen at higher altitudes far outweighs the ROI of wind turbines mounted on conventional steel towers.

I solved a simple idea of placing the gererators (plural) and all the electrics at the base of the towers some years ago.

I have lots of ideas but I am just an older Canadian Civil temporarily resident in Santiago Chile without enough funding to do actual research on my own.

If my comments are of interest to you, contact me directly by email.

Paul V. Preminger email: paulpreminger@hotmail.com

Betz limits have been accounted for.

Having the gnenerator and ancillary equipment at ground level is a great advantage already available to vertical axis wind turbines. It is a novelty for propeller type wind turbines.

The rotational speed of the generator shaft can be increased with contra-rotating rotors. The efficiency is increased around 10% but by no means three times as much.

Michael, does the rule of Betz refer to the design capacity of the turbine generator, or to the potential kinetic energy in the available wind? Those are not the same.

Current information available suggests that bats, for example, are more subject to deleterious or deadly interactions with wind turbines on evenings when wind speeds are lowest. On the other hand, a rotor speed of 3.3 RPMs instead of 17-23 RPMs might (or might not) result in a lessening of deadly effects on bats and other wildlife.

If we assume that the power curves of the conventional turbines have a cp around 0.4 than this turbine has a cp near 1.0 (extrapolating the point at 10 m/s)

I can not believe this, this is against the rule of Betz, which will not allow to have a higher capacity factor than 0.59 for free stream rotors.