Timken Tapered Double Inner (TDI) Roller Bearing is designed to extend bearing life and improve system performance for three-point mount wind turbines. As a global leader in wind bearing design and manufacturing, Timken collaborates with wind turbine owners and operators to help solve mainshaft application issues and improve drivetrain performance. Timken TDI Roller Bearing for mainshaft wind energy applications is the result of working with our end-users.

Timken Tapered Double Inner (TDI) Roller Bearing is designed to extend bearing life and improve system performance for three-point mount wind turbines. As a global leader in wind bearing design and manufacturing, Timken collaborates with wind turbine owners and operators to help solve mainshaft application issues and improve drivetrain performance. Timken TDI Roller Bearing for mainshaft wind energy applications is the result of working with our end-users.

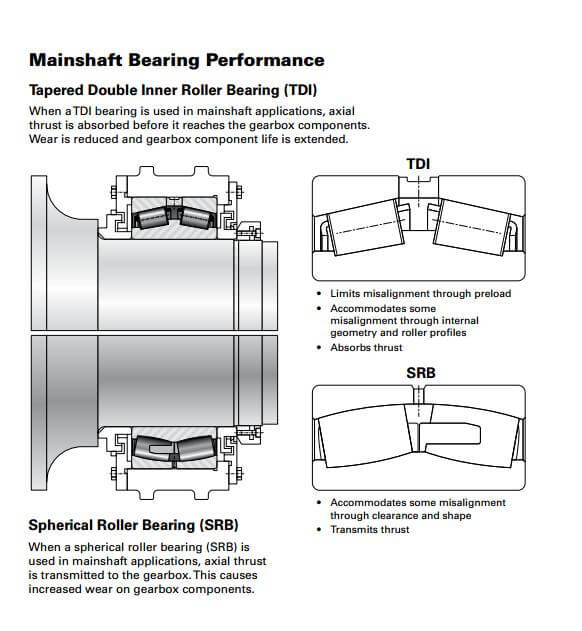

Longer bearing life, reduced component wear and better drivetrain performance are key to reducing costly wind turbine repairs. The TDI bearing is designed to be a drop-in replacement for the mainshaft spherical roller bearing (SRB). With the TDI bearing, wind turbine operators have these advantages:

Ease of Installation: The existing OE housing can be used when installing a TDI bearing to replace a mainshaft SRB.

Extend Bearing Life: Using a preloaded TDI bearing helps significantly reduce skidding and smearing damage, and also minimizes edge loading common with mainshaft SRBs. As a result, there is less wear and less debris, further extending bearing life.

Reduce Gearbox Wear: The preloaded TDI bearing increases system rigidity and decreases axial thrust into the gearbox load. This reduces wear and extends gearbox component life.

Filed Under: Bearings, News