parker.com

Maintaining lubricating and hydraulic oil once meant changing it on a set timetable. More recently, it makes sense to keep it as clean as possible, let the oil tell when it needs changing, and let it tell how equipment in the nacelle is performing.

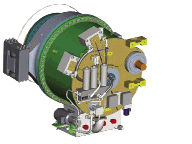

The gear box lube oil filter from Parker Hannifin Corp., (circular light grey and to the right) can have a service life exceeding the standard six months.

Filters on wind turbine hydraulic systems are essential for removing contaminants from fluids, the primary cause of failure in lubricated and hydraulic equipment. Such failures lose revenue and increase maintenance and associated costs. Worse yet, failures lessen the confidence buyers might have had in a particular machine or manufacturer.

There is a solution to the problem in innovative devices, such as magnetic pre-filtration, which increases the lifetime of hydraulic filters up to 40%. Further development in the use of patented media and element design have seen life of filter elements go from a nominal 3 to 6 months up to 15 months – a significant increase and reduction in maintenance costs for turbine owners. What’s more, the later figure is not a limit. Recent developments will increase the level of reliability of lubrication systems even further.

More complete assemblies

In the recent past, wind turbine OEMs built fluid filtration systems by assembling components not all from the same manufacturer. While such systems worked reasonably well, hydraulic-component companies are now designing complete lubrication-oil systems for the gearboxes of wind turbines. These systems include filters, pumps, valves, coolers, and heaters as well as manifolds and piping to connect components. The advantage is that the assemblies are more thoroughly tested and proven and carry the assurance of reliability from a qualified supplier.

For OEMs that must buy subsystems, another emerging industry trend will assist by providing turbine-specific 3D-models of the hydraulic equipment which can be imported directly into the 3D-CAD-gearbox models or some preferred location in the CAD model of a nacelle. This lets the hydraulic supplier take responsibility for the system and saves the OEMs significant time to accelerate product to market, money, and resources. Further, streamlining the supply chain ensures prompt delivery of consumables and service parts around the globe via a synchronized logistics network.

The 7.2 x 6.1 x 3.4-in iCount Particle Detector from Parker provides contamination control. A few features includes independent monitoring of system contamination trends, and early warning LEDs or digital display indicators that tell of low, medium, and high contamination levels. The unit needs only 3 sec to take a sample. It works at flow rates of 40 to 140 ml/min, but works best at 60 ml/min. Working pressure is up to 6,000 psi.

At least one new filter element designed for wind turbines to ensure sufficient and effective filtration levels and prevent the filter from going into bypass mode, even during cold starts. Also, an integrated offline filter with water removal capabilities secures the best possible conditions of the oil used in these demanding applications. Existing systems on turbines can be upgraded with these new capabilities.

An eye on oil

Oil condition monitoring is gaining favor because turbines are often perched 60 m off the ground and more, making access inconvenient. Some companies maintain condition monitoring centers to manufacture and supply particle counters and detectors as well as moisture sensors, additional indicators of oil cleanliness. One recent oil condition monitoring tool, the iCount Particle Detector (IPD), is a laser-based device intended for monitoring high viscosity fluids. It continuously measures solid contamination levels in the lube oil using laser and light-obscuration principles.

Connect the filtering equipment this way. Detailed CAD models can show technicians exactly what goes where.

module, which control oil flow and pressure. A drawback on conventional systems of this sort is that they spot air bubbles in the oil, the result of splash feed lubrication, and identify them as contaminants. That generates spurious results. As such, bubbles must be suppressed before they reach the IPD. To do so, the IPD cleverly raises the oil pressure in the monitoring system in excess of 100 bar which compresses the air bubbles below the unit’s detectable limit so they are not mistaken as debris

It should be noted that traditional wear debris sensors are limited to the size of the particle they can detect, somewhere in the region of 100µ or larger. The IPD, however, measures down to 4µ and so provides an earlier warning of wear and potential component failure than conventional methods.

Three-D CAD models of hydraulic equipment and filters let OEMs “build” realistic nacelles to get a better idea of where equipment is most effectively mounted before building physical prototypes. The green housing is a turbine gearbox. Hoses and tubing show connections to Parker Hannifin filters and condition-monitoring devices.

integrated moisture sensor that allows monitoring the gradual increase of dissolved water without requiring a separate or stand-alone device. Signals from the detectors can then easily be incorporated into an existing monitoring system or in a stand-alone version.

Engineered filtration solutions for wind turbines, such as these from Parker, improve the life of critical components such as gear boxes and bearings. The filter elements extend the life of the filters and reduce the number of filter changes, thereby increasing the uptime and reducing service costs. Magnetic pre-filtration ensures ferrous particles are minimized in the oil circuit and oil and filter life is further extended while progressive degradation in the bearings/gearbox is minimized.

These recent ideas in oil monitoring allow minimizing or eliminating the use of bottle sampling. Results then become available in real time, instead of waiting days for lab results. This also allows planning the preventative maintenance for turbines, thus reducing downtime and cost of maintenance significantly. WPE

Filed Under: Components, Hydraulics, Lubricants, News

I am in college doing a report on lubrication monitoring, and we have to know the price of everything we put in our turbine, I need to the the price of the iCount Particle Detector from Parker. please get back with me at your earliest convience.

Thank You,

Troy