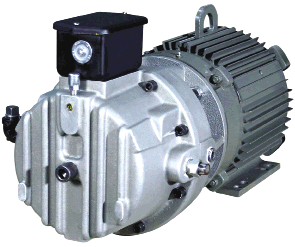

MagnaShear motor brakes work by shearing oil for longer service life even in demanding applications. Compressing a fluid shears its molecules– thus imparting torque to a stationary side. The brake eliminates the wear of friction surfaces. A fluid recirculator dissipates heat, a common problem in dry braking systems. Eliminating wear significantly increases service life and almost eliminates adjustments. Oil shearing provides a smooth “cushioned” stop which reduces shock to the drive system, further extending service life of downstream components. The motor brakes work well in applications where the motor reverses, such as yaw motors.

MagnaShear motor brakes work by shearing oil for longer service life even in demanding applications. Compressing a fluid shears its molecules– thus imparting torque to a stationary side. The brake eliminates the wear of friction surfaces. A fluid recirculator dissipates heat, a common problem in dry braking systems. Eliminating wear significantly increases service life and almost eliminates adjustments. Oil shearing provides a smooth “cushioned” stop which reduces shock to the drive system, further extending service life of downstream components. The motor brakes work well in applications where the motor reverses, such as yaw motors.

The enclosed MagnaShear brakes are impervious to moisture, dirt, and dust. The design uses a layer of automatic transmission fluid between brake disc and drive plate. Along with heat removal and torque, the fluid serves to continually lubricate all components. MagnaShear brakes provide significantly longer service life than conventional designs and are characterized by virtually maintenance-free operations. These motor brakes accommodate a wide range of applications. Spring-set-torque ratings are available from 3 to 1,250 ft-lb. The brakes can be sized to a torque independent of the motor-frame size or horsepower.

Force Control Industries Inc.

Filed Under: Pitch & yaw