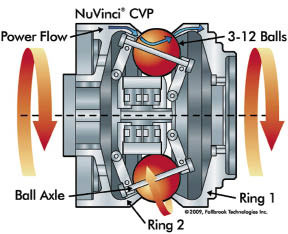

A continuously variable transmission with features similar to planetary gearbox could improve energy capture for smaller wind turbines along with reducing capital costs. The transmission works by changing the contact position on a set of planetary balls on which input and output disks ride. Continuous ratio changes adjust rotor speed as wind speed changes. This lets the rotor maintain high efficiency at all wind speeds. Developer Fallbrook Technologies Inc. says its NuVinci CVP (continuously variable planetary) can work in micro turbines of less than 1 kW up to utility class 1MW+ turbines. Viryd Technologies, Cedar Park, Texas (viryd.com) has the license from Fallbrook for the use of CVP in wind turbines.

Conventional small turbines suffer several shortcomings. For instance, those called constant-speed units work at low efficiency at most speeds except one, the design speed or design condition. What’s more, most wind turbines use expensive permanent-magnet generators. These can have as many as 38 poles, contributing the high cost of wind turbines.

The Viryd design using the NuVinci CVP provide a high performance wind turbine without requiring magnets made with rare earth materials, resulting in significantly lower costs.

“Think of the rotor as a flywheel,” says Viryd CEO John T. Langdon. “It stores energy as motion during a gust and takes it out during a lull. By using the variable rotation of the CVP we can take energy out of a rotor during lulls or store energy during gusts while keeping the generator turning at a proper speed to deliver power into the grid. This ability to absorb torque spikes smoothes the variable effects of the wind and helps keep the Viryd system operating longer and without interruption.

“Think of the rotor as a flywheel,” says Viryd CEO John T. Langdon. “It stores energy as motion during a gust and takes it out during a lull. By using the variable rotation of the CVP we can take energy out of a rotor during lulls or store energy during gusts while keeping the generator turning at a proper speed to deliver power into the grid. This ability to absorb torque spikes smoothes the variable effects of the wind and helps keep the Viryd system operating longer and without interruption.

The NuVinci CVP can also slow a rotor in high winds, shedding the exact amount of power necessary to maintain peak energy production, and thereby capture more energy from the wind. The unit, says Langdon, precisely controls rotor speed, letting a turbine use a rotor with about 20% more area and keep the rotor near its optimum rotational speed, thereby capturing more energy. In addition, turbines equipped with the CVP don’t need an inverter because the transmission shifts with wind-speed changes, letting it eliminate the approximately 14% inverter losses.

An elasto-hydrodynamic fluid eliminates metal-to-metal contact inside the device. “Its simplicity relative to other types of variable speed transmissions, roughly one-tenth the parts, means it should be the most reliable,” says Langdon. A version for bicycles, the first commercialized product, is sold as a sealed unit with an 8-year warranty. The company says the low failure rate in the field is less than initial predictions. Lab units have been tested to more than 100,000 kilometers.

The NuVinci can also be scaled up by using several units on a single shaft, or driving several units from a common “bull gear”, or making a larger unit with more planets (balls), larger planets, or larger input and output discs.

“Larger versions of the trans-mission have been developed. We are confident the design can be scaled up all the way to MW class wind turbines, because the math for choosing the number of planets and their dimensions is well defined and based on keeping the internal stresses of the device roughly the same,” he says.

Filed Under: Uncategorized

Almost a year ago Viryd Technology took my down payment. As of yet, they have NOT built my turbine and has NOT returned my money.

Mr. Niemier:

It sounds like it’s time for legal action.

Paul