Tahnee Miller / Electrical Design Engineer / Ulteig / www.ulteig.com

The foresightful worker is attired in personal protective equipment to safeguard against the arc-flash.

Workers in the wind power industry face several potential hazards that include arc flashes, electrical discharges that occur upon opening energized circuits. Without proper training and safeguards in place, one wrong move could lead to thermal burns, electrical shock, and falls as a result.

As a regulatory body, the Occupational Safety and Health Administration (OSHA) is the main federal agency responsible for the enforcement of safety and health legislation in the United States.

One important standard set by the organization requires employers to mark electrical equipment with signs, warning personnel of potential risks, including arc flashes. The magnitude of a potential arc-flash hazard can be quantified in terms of incident energy.

Until 2014, OSHA offered no regulations or recommendations on a preferred calculation method. Because there are several methods for calculating incident energy, different organizations provided inconsistent calculations for different types of equipment. OSHA has since aimed to reduce uncertainties and increase jobsite safety, thanks to their new ruling.

Understanding arc flash

NFPA 70E-2012, Standard for Electrical Safety in the Workplace, is the standard that explains and provides guidance for arc-flash hazard analyses. NFPA 70E-2012 defines an arc-flash hazard as: “A dangerous condition associated with the possible release of energy caused by an electric arc.” (Source: Handbook for Electrical Safety in the Workplace, 3rd Edition. Edited by Jeffrey S. Sargent, and Michael D. Fontaine, PE. Copyright 2012)

Calculations for arc-flash hazards on wind farms differ from many other applications in that they can be ascertained from two sources: the utility system external to the wind farm, or from the wind turbine generators. In either case, a hazard exists if a person may be exposed to an arcing fault on energized electrical equipment.

According to the NFPA 70E-2012 Standard, an arc-flash hazard analysis is determined by:

1. Incident energy

A quantitative calculation of the thermal energy to which a person may be exposed, incident energy is measured in calories per square centimeter (cal/cm²). Incident energy exposure changes based on a variety of factors, including: the type and voltage of equipment; how far a person is away from the equipment (i.e. working distance); the fault current available; and the expected duration of the fault.

2. Arc-flash boundary

Arc-flash boundary is the distance at which the incident energy equals 1.2 cal/cm². It represents the point at which personnel need to wear personal protective equipment (PPE) to safeguard against a potential arc-flash hazard.

3. Personal protective equipment (PPE)

Rated by the manufacturer (based on incident energy in cal/cm²), PPE is selected by a facility to protect its personnel from an arcing fault. NFPA 70E offers tables that correlate specific ranges of incident energy to a hazard/risk category (HRC), which link to a recommended PPE. For example, HRC 3 recommends PPE with a system arc rating of at least 25 cal/cm², which may include an arc-rated suit jacket, pants, hood, gloves, leather work shoes, a hard hat, safety glasses, and hearing protection. Ultimately, PPE is selected and enforced by the owner of the electrical equipment, and NFPA 70E serves to provide recommendations only.

Calculating arc flash

The process of quantifying arc-flash hazards for electrical equipment has been evolving ever since the 1980s. Different methods are described in national consensus standards, including in NFPA 70E-2012, IEEE 1584, and NESC 2014.

NFPA 70E-2012 Informative Annex D lists several calculation methods, for instance, but only for informational purposes. These include the process and limitations of calculations methods from:

- A 1982 paper written by Ralph Lee,

- A 1998 paper written by Doughty, Floyd, and Neal,

- IEEE Standard 1584, and

- ANSI/IEEE C2 NESC, Section 410.

IEEE Standard 1584 has been the default method used in most software packages typically applied in the wind power industry for equipment less than or equal to 15 kilovolts (kV). The Ralph Lee calculation method is usually employed for equipment greater than 15 kV, although the NESC tables from Section 410 for high-voltage equipment is sometimes preferred depending on the type of equipment being studied.

Regulating arc flash

Due to the authority granted by Section 5(a)(1) of the Williams-Steiger Occupational Health and Safety Act, OSHA is responsible for enforcing arc-flash safety.

In April of 2014, OSHA created a final rule of 29 CFR Parts 1910 and 1926, which became effective in July of 2014. It includes new and revised provisions for operations and maintenance (O&M) of electric power generation, transmission and distribution lines, and related equipment.

With consistency in mind, OSHA’s final rule makes changes to several safety-related topics, addressing the different methods of arc-flash calculations. It compares calculations for similar equipment, noting the different results obtained with each method, and pointing out the basis and limitations of each one.

According to the Department of Labor Occupational Safety and Health Administration, the final rule “replaces the incorporation of out-of-date consensus standards with a set of performance-oriented requirements that is consistent with the latest revisions of the relevant consensus standards.” (https://federalregister.gov/a/2013-29579)

Developing arc-flash studies

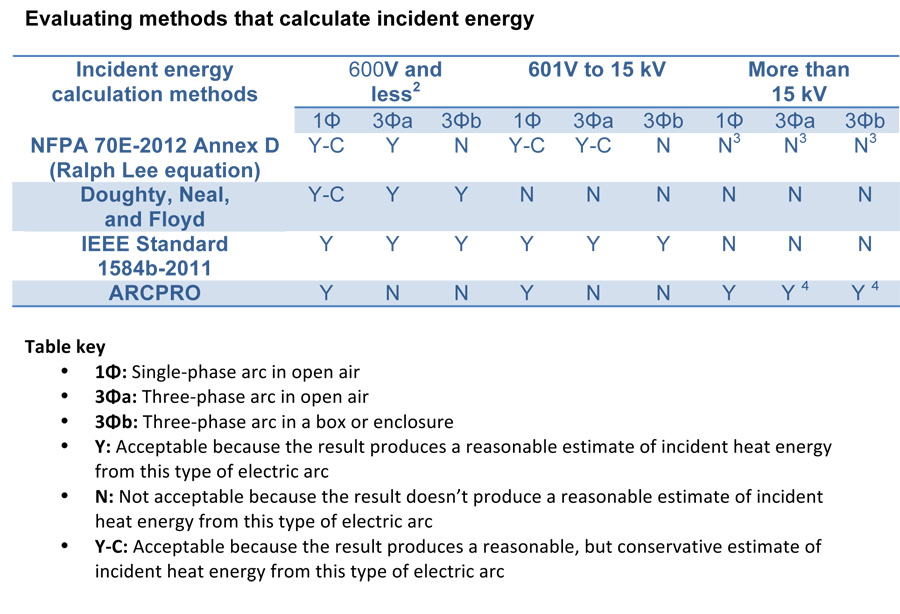

Appendix E to Subpart V of Part 1926 – Protection from Flames and Electric Arcs summarizes OSHA’s recommendations. The following table presents OSHA’s calculation methods, suitable for equipment 600V and less, between 601 and 15 kV, and greater than 15 kV. It also demonstrates calculations for single-phase flash arcs in open air, three-phase arcs in open air, and three-phase arcs in an enclosure.

Table notes

- The Occupational Safety and Health Administration considers these methods reasonable for enforcement purposes when employers use the methods in accordance with Table 1. However, employers should be aware that these methods don’t necessarily result in estimates that offer full protection from internal faults in transformers and similar equipment, or from arcs in underground manholes or vaults.

- These voltages presume a three-phase arc. If this isn’t the case, an employer must demonstrate that only one phase is present or that the spacing of the phases is sufficient to prevent a multi-phase arc.

- Although OSHA deems this method acceptable for assessing whether incident energy exceeds 2.0 cal/cm2, its results are conservative and often unrealistic at voltages of more than 15 kV.

- OSHA deems the results of this method reasonable when the employer adjusts them using the conversion factors for three-phase arcs in open air, or in an enclosure, as indicated in the program’s instructions.

To summarize, the IEEE Standard 1584b-2011 equations are applicable for equipment less than and including 15 kV. For equipment greater than 15 kV, the ruling maintains the Ralph Lee method can be used, but only to assess whether the incident energy exceeds 2.0 cal/cm². This is because the results are quite conservative, and tend to be unrealistic for this voltage level.

Interestingly, OSHA’s ruling also recommends ARCPRO, a software program based on an electrical arc model 4 for equipment greater than 15 kV. ARCPRO was developed by HD Electric, the company that provided the test data for low-voltage equipment used to develop the equations in IEEE Standard 1584 and the tables in NESC Section 410; however, these only apply to a limited set of equipment types and voltages.

ARCPRO’s calculations are from tested results of single-phase, open-air arcs. The results have been deemed reasonable, so long as they are adjusted using conversion factors for three-phase arcs in open air, or in an enclosure, as indicated in the program’s instructions.

Ensuring personnel are safe and sound should always be a priority of the wind industry. OSHA’s final ruling of 29 CFR Parts 1926 and 1910 provides much needed consistency for calculating incident energy for equipment of different voltages. WPE

Filed Under: Safety