A software developer working with NREL-conceived control modules has introduced a software-based, plant-level control platform in which all turbines on a wind farm work together to extract the maximum energy from wind streams. Developer WindWISDEM says its repowering service allows wind-farm operators in many cases to extend production Tax Credits (PTC) for an additional 10 years.

Cloud-computing services also make such turbine control more feasible because it lowers the cost of the considerable computing needed to get the most out of a wind farm with 100 turbines or more. Company CEO James Kiles says the WindWISDEM focus is to steer wakes away from downstream turbines to boost their outputs and decrease damage from stress.

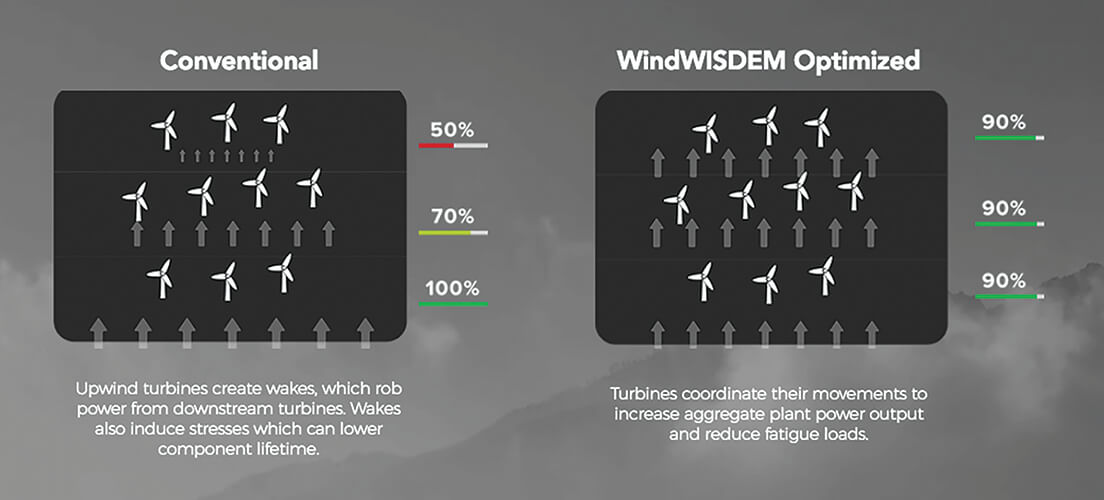

Left: Upwind turbines create wakes which rob power from downstream turbines. Wakes also induce stresses which can lower component lifetime. Right: With WindWisdem working, turbines will coordinate their movements to increase aggregate plant power output and reduce fatigue loads.

Separately, WindWISDEM is advancing wake theory with its team. “Wake turbulence comes from many wind force inputs,” Kiles says. “As a result, the center line of wake direction is not going to be parallel to the wind impact. We are developing formulas for measuring and understanding wake center lines and curvature that are built into our cloud platform to manage calculations that are becoming even more complex.”

To handle such complexities, recently improved wake theories advanced by industry experts from places such as DTU and Siemens have been added to the system. This is important because as newer turbines are built larger, their wakes or displacements will be larger, making management more important to maximizing ROI.

This repowering technology is said to deliver increased revenue from energy production for existing turbines by up to 10% and possibly more. Its deployment can be critical to meeting the IRS’ requirements for PTC at a fraction of the cost of purchasing expensive new hardware. Advanced simulations conducted by scientists project that power output at any given instant could be twice a wind farm’s production when turbine settings are optimized.

The repowering opportunity lies in three areas. “First, understanding and calculating for wind displacement or wake from individual turbines. Second, using software optimization to understand the impact of displacements and suggest turbine adjustments. And third, a full wind farm deployment, where required calculations grow exponentially with more turbines and bigger opportunities for gains. To address the wind farm operation intelligently, you need cloud-computing services to handle the calculations,” says Kiles.

He adds that the new service reduces cost burdens on repowering wind farms that were previously forced to consider only replacing working production equipment to meet improvement thresholds required to extend PTCs.

“By leveraging their existing infrastructure with intelligent software, operators will be able to quickly and inexpensively repower,” Kiles says. Now is a good time to do so given the reduction in wind-energy prices and the pending expiration of the production tax credit in December of 2019. “Securing an additional 10 years of PTCs at comparatively minimal cost is a common-sense approach,” he adds.

While wake steering and avoiding the impact of turbulence on downstream turbines are important goals of the software, in some cases it is possible to maximize benefits of wind turbulence. “This can happen in low-to-moderate speed winds, where this kind of technology will be most impactful. Interestingly, low winds generally occur at the time of maximum pricing in the industry,” says Kiles.

There’s been minimal activity in terms of actually repairing old turbines and giving them upgrades. Most upgrades replace old machines with new turbines. Kiles says a better strategy would be to first optimize around the concept of managing displacements. After improving power outputs and with more revenue flowing from power production, then perform the hardware upgrades.

The company is conducting a proof of concept now, and before this year is out Kiles expects to have 20 proofs of concept in place – 20 different wind farms. “Beginning in July, our software will be available to optimize any wind farm that wants to be optimized,” he says.

Filed Under: News, O&M, Software