Xiao Chen / Associate Professor at IET Wind / Chinese Academy of Science

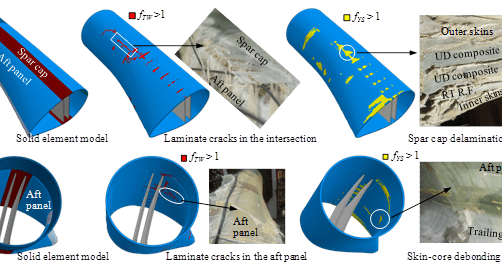

Results from a finite-element analysis presents solid element with photos of physical failure. Full-scale structural tests have enabled an in-depth understanding of how composite blades respond to specific applied loads.

The Abstract of Professor Chen’s paper is here:

Full-scale structural tests have enabled an in-depth understanding of how composite blades respond to specific applied loads. Blade strength can be validated, and necessary modifications made to improve the structural performance or reduce blade weight, or both.

This study revisits the structural collapse of a 52.3 m composite blade with new research content. Specifically, the present work examines the chain of events captured in the video record of the blade collapse and provides direct phenomenological evidence of how the blade collapsed in its ultimate limit state.

In addition, 3D strains are investigated by reconstructing the root transition region of the blade using solid brick elements in a finite element analysis. The strain components responsible for particular failure characteristics are identified. The structural response of the blade is investigated numerically. Interactive failure phenomena associated with strains, local buckling, and material failure are examined in detail.

The study shows that local buckling of the sandwich panels with unbalanced construction drives progressive failure of the composite materials and eventually leads to blade collapse owing to a significant failure of the load-carrying spar cap. Design modifications of the blade are proposed and validated with the test of a new blade.

With respect to the latest DNV GL standard, this study notes a possible method to predict delamination and skin-core debonding failures. This study also recommends the use of three-dimensional solid elements in finite element analysis, especially when the strength and failure of large blades are of concern.

Professor Chen says his team as published the full paper in Wind Energy and it is available for a charge here: http://onlinelibrary.wiley.com/doi/10.1002/we.2087/full

Filed Under: Blades, News