The AWEA Windpower 2014 Conference and Exhibition, with slogan “Transformation in Motion,” kicked into high gear today with a sharp focus on the future, as federal officials previewed an ambitious vision for the growth of U.S. wind energy to 35% of the grid by 2050. Windpower Engineering and Development staff is on hand, of course, to report the latest.

Phoenix Contact, a German company, manufactures the widest breadth of terminal block products in the industry, says manager Deralee Bowlin. The terminal blocks pictured here are rail-mounted instead of connected directly to a control cabinet, making it easier for technicians to assemble and swap parts. The blocks feature uniform bridging.

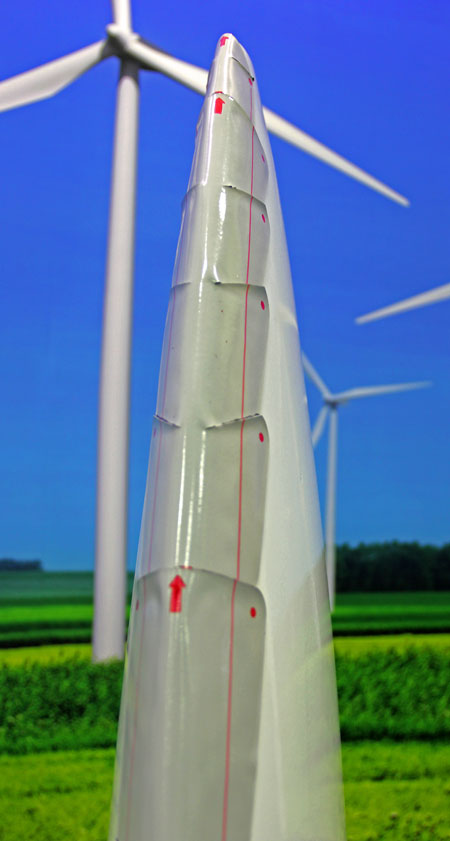

Project owners often find that wind resources at a site are less than predicted. To help solve the problem, GE’s renewable energy business has introduced a seven-meter blade extension. The extensions can take GE wind turbines from a 77-meter rotor to a 91-meter rotor, which can increase output by 20%. “We can take a turbine and adapt it to its environment,” says Keith Longtin, GE’s general manager for its wind product line. The extension will be considered for use on a turbine-by-turbine basis.

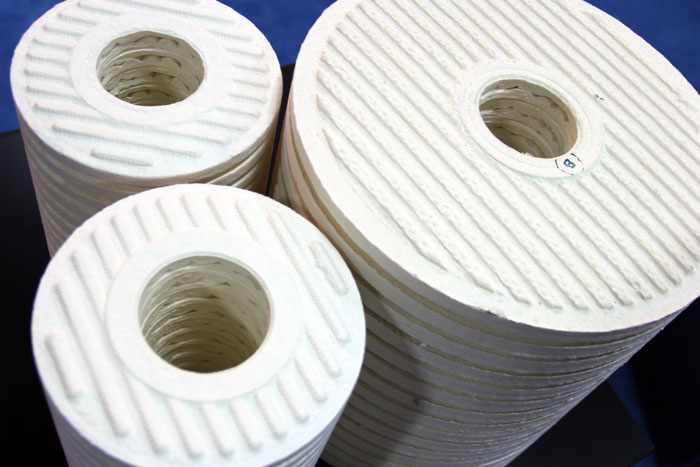

CJC manufactures oil filtration systems, which can provide the “cleanest oil in the world,” says Claus Kejling, a key account manager for the Denmark-based company, which has an office in Atlanta. These filters remove invisible particles, humidity, and resins from turbine oil.

Wind Access Engineering provides temporary suspended scaffolding for blade inspection and repairs. The company leases, sells, and services various platforms for blade maintenance, including the Kaeufer blade access system modeled here. This particular system is fully UL tested.

This ergonomic hub hatch tool from Snap-On is an example of a custom solution the company produced for an OEM. “Before, they were using a device similar to a church key, and there was no way to secure it,” says product manager John Martell. “We climbed, looked at the situation and developed this tool, which helps them do their job better.” The hub hatch tool secures to a belt with a retractable cord.

Chicago-based Fuchs provides high-quality lubricants to a wide range of industries. This color-coded model shows the different areas where lubricants are used in a turbine. Blue is the gearbox; green is the main bearing; red is the pitch bearing; orange are yaw gearboxes; and brown is the yaw bearing.

Texas-based TGM Wind Services rolled its massive skylift into AWEA Windpower. TGM pioneered skylift access systems and provides the service to multiple industries including gas and coal.

Windpower Engineering and Development sales manager Courtney Seel and Aztec Bolting Services owner Larry Garza III discuss the company’s newest custom motorcycle. The company’s motorcycles have won numerous awards, and Windpower 2014 attendees need to stop by the booth to see why!

ENSA North America trainers practice a rescue while dangling from a 30-foot-tall training tower. ENSA continues to be a leader in inventing, perfecting, and refining work-at-height rescue techniques. ENSA helps meet the needs of health and safety executives and program managers faced with an evolving compliance environment, operation deadlines, climber criteria, program limitations, and the requirement for skilled personnel.

To protect turbine blades, IER Fujikura provides the Blaid protective sheet, abrasion-resistant rubber sheets with a layer of Aramid woven fabric for high durability. No adhesives or edge sealants are required. According to the company, a three-year test on a 1.5-MW turbine showed no record of wear on blades.

The dome at the rear of this truck houses a Ka-band radar that is used to map wake effects and wind flows at wind farms. Led by research professor Jerry Guynes, Texas Tech University custom developed this experimental technology, which is based on meteorological radar for tornadoes and hurricanes.

Windpower 2014 attendees: Read the most recent windpower news on the Windpower Engineering and Development homepage, check our Twitter (@windpower_eng) for updates from the show floor, and each day watch out for a new photoblog!

Filed Under: Construction, Turbines