Editor’s note: The material highlighted here may be able to do the work of some steel parts in a nacelle, thereby bring its weight down.

The new Kyron MAXseriesfrom Piper Plastics bridges the performance gap between components produced via standard injection molding compounds and pre-preg lay-up composite materials. Kyron MAX materials allow parts to be injection molded at high volumes with strengths that approach lay-up composite and metals.

The Kyron MAXseries significantly changes the way design engineers think of plastic materials. The unique combination of a proprietary high pressure molding technology, coupled with a state-of-the-art material technology, is used to produce the highest strength structural components made from thermoplastics today. These new materials offer mechanical properties which meet, and in some cases exceed, those of metals.

The Kyron MAXseries significantly changes the way design engineers think of plastic materials. The unique combination of a proprietary high pressure molding technology, coupled with a state-of-the-art material technology, is used to produce the highest strength structural components made from thermoplastics today. These new materials offer mechanical properties which meet, and in some cases exceed, those of metals.

Generally speaking even the strongest moldable plastics cannot match the strength of metals so the metal part geometry must be altered and re-engineered to utilize plastic materials. This often involves adding much more material volume of the plastic which can compromise the weight savings and cost reduction advantages of the conversion to plastics. Kyron MAXpolymers offer mechanical properties that sometimes meet or exceed those of metals. The resulting component design can more easily replicate the original metal design, minimizing the mass of plastics required while realizing all of the engineering benefits of the plastic materials.

A few features of the Kyron MAX series include:

- Tensile strength – Higher than steel (greater than 100,000 psi)

- Weight – Nearly 75% lighter than steel and about 60% lighter than titanium

- Lower component cost – The ability to mold components in a high volume tightly controlled process significantly reduces the manufacturing costs associated with pre-preg lay-up materials.

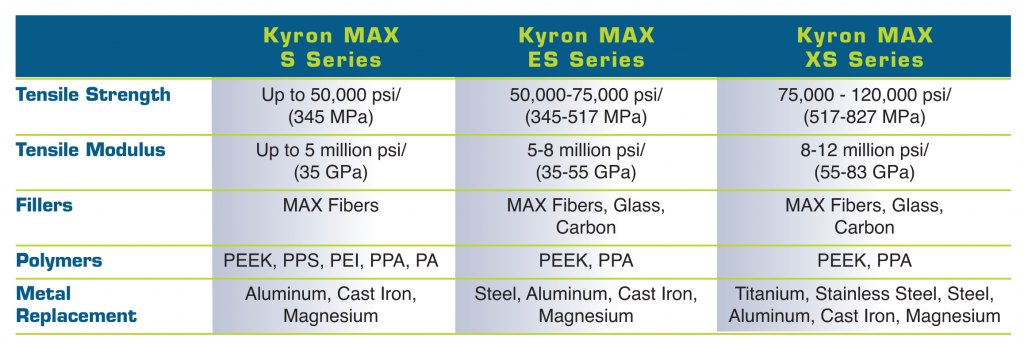

- Product flexibility – The product will be available in three performance levels allowing designers to select a cost vs. performance option to match their needs.

- Better “practical toughness” due to lower filler loadings – The revolutionary filler generates high mechanical performance with lower fiber content increasing the material’s strain, which allows the part to yield and not fracture.

“We understand factors critical to component design, the influence of reinforcements and additives, and the effects of processing and tool design,” says Dave Wilkinson, Piper’s Materials Engineering Manager. Knowing the complexities of plastics is essential to reliable replacement of metals.”

.

Piper Plastics

http://www.piperplastics.com/kyronmax/kyronmax.html

Filed Under: News