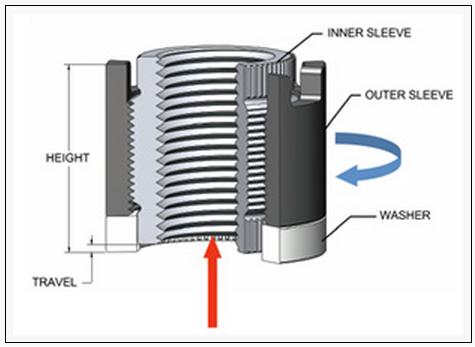

The HYTORC NUT is a three-piece fastener that will directly replace any type of helical nut. The HYTORC nut’s interlocking surfaces provide pure axial bolt tensioning without the need for an external reaction point. Furthermore, the HYTORC NUT provides accurate bolt loading because all frictional forces are integral to the controlled Clamp’s surfaces.

As the outer sleeve turns (blue arrow), the inner sleeve moves upwards

(red arrow). The washer spline rotationally couples the inner sleeve with the washer preventing the inner sleeve from turning while providing a solid reaction point for turning the outer sleeve.

A closer look at the series shows that the inner sleeve is connected to the bolt end and is held stationary by the HYTORC machine during operation. The outer sleeve which turns on the washer face is connected to the inner sleeve by an acme thread (ASME/ANSI B1.5) providing a higher turning friction to the inner sleeve and washer than the outer sleeve. When the action force of the HYTORC machine is applied to the outer sleeve and its opposite reaction force to the inner sleeve, the outer sleeve turns at a known coefficient of friction on precision machined surfaces. This results in the inner sleeve (and the bolt) rising in a torsion-free, pure axial motion applying pre-calibrated tension to the bolt.

The hardened washer remains stationary during the operation eliminating facial galling. Pure, mechanical bolt tension is provided hands free (even on inverted applications) without the use of bridges, pullers or jack screws and without relying on bolt relaxation to seat the nut! The HYTORC NUT is rated for temperatures up to 1,000°F (537°C) and is available for any bolt size (imperial/metric), any thread configuration and upon request, is available in specialty materials to suite the application and environmental conditions

Install the nut, set the pump pressure, place the tool and simply push a button on the remote control to achieve unprecedented bolt load accuracy to + 5%, guaranteed.

The HYTORC NUT is well suited for limited radius applications. Applications set into a pocket or a counter bore situation pose a problem with conventional tooling. Standard drive extensions and machined down compromising the safety of the operator. The design and the mechanics of the Clamp allow positioning the HYTORC machine away from the conflict area!

HYTORC

www.hytorc.com

Filed Under: News