By Paul Dvorak, Editor

Windpower Engineering & Development

You’ll be forgiven if you think that cables are a “set and forget” type of component. Not so. In truth, cables in wind turbines must tolerate abrasion from vibration, oil on insulation, and remain flexible to a bone-chilling -40°F — and more. Then as the wind industry becomes more digital, it calls for more data from more sensors, which require more connectors.

Passing 10,000 cycles in a torsion test is significant because it exceeds the torsion life cycle requirements from all of the global wind turbine manufacturers. The recent TRAYCONTROL X cable from HELUKABEL is a NFPA 79 compliant flexible control power cable with cross-linked (thermoset) polyethylene insulation. It works in dry, humid, and damp environments, in pipes, underground, and for open, unprotected installation within the turbine. The cable is rated for use in 1,000 V wind turbine cable tray applications.

But as things have gotten more complicated, the industry has responded with new products and updated standards, which will guide industry growth. In fact, a recent report from Research and Markets forecasts the growth of the global wind-power cables market at a compounded rate of about 7% from 2017 to 2021. Here are a few recent cable and connector development, and outlooks that will drive that growth.

Tolerating cold

Electrical cables are exposed to harsh temperature extremes where low and high-temperature fluctuations affect a cable’s performance. Cables are now tested in accordance with UL, CSA, and NEC standards for applications that require bending in cold temperatures down to -40°F (-40°C).

Cold bend tests determine how the entire cable (conductors, insulation, and jackets) might react to cold-temperature bending. For the test, cable samples are cold soaked to a specified temperature for a number of hours. After the cold soak period, the samples are wound around a steel mandrel determined by the cables’ outer diameter. After winding, the cable is removed and examined for surface damage, such as cracks, splits, and tears. The cable passes the UL cold-bend test when there is no visual surface damage and further electrical test reveal no other issues.

One cable manufacturer says a recent design has successfully surpassed two tough mechanical tests to ensure its safety and performance capabilities in wind turbines found throughout North and South America. HELUKABEL says its TRAYCONTROL X has passed the UL -40°C Cold Bend Test and a torsion test of 10,000 torsion cycles.

Testing by twisting

Electrical cables exposed to continuous movements and vibration force them into near constant flexing, which produces mechanical stresses in them. This can degrade their performance and lead to failure. One place this occurs is in the tower. As a wind turbine’s nacelle rotates, cables in the loop twist and tighten onto one another. This places torsional stress on the cable’s components at every level — conductors, jacketing, and insulation.

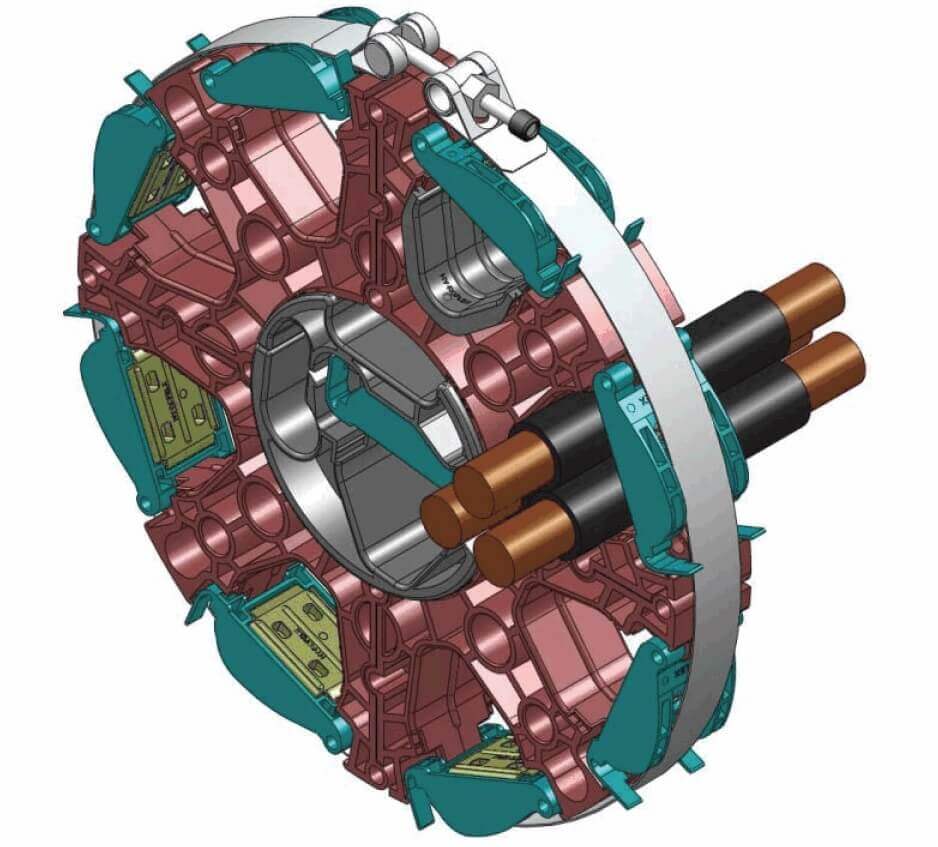

The compact modular design of the SOHL allows for proper heat dissipation to keep cables cool for maximum efficiency and to avoid excess wear in the insulation. The number of units needed per drip loop is turbine-specific.

To test new designs, one cable manufacturer operates an R&D lab that duplicates a section of a wind tower, big enough to test a full-sized cable in a drip loop. The tower-lab also allows exposing cable to various climates. A cycle in the twist test is defined as 1,080° (360° x 3) rotation in either direction (clockwise and counter). The rotation rates allow for up to one cycle per minute.

After reaching a required cycle count, cables are inspected for visual defects, such as abrasion and cracking, and internal components are examined for signs of failure, such as conductor strand breakage.

Wear in the loop

The drip loop is that bundle of cables responsible for carrying power, data, signals, and communication for everything generated inside a nacelle. The loop is needed to provide slack for the turbine to yaw a few revolutions as it works to face the wind. While the cables in this loop meet wind-industry standards (for torsion, oil resistance, and temperature), current industry practice of tightly bundling them has serious impacts.

The biggest problem with closely arranging cables in this manner is there can be as many as 16 of them tightly bound together, twisting and rubbing against each other. This arrangement creates excessive heat and wears down the jacket insulation, ultimately exposing a cable conductor that can carry from 600 to 1,000V. This wear can appear only a few months after the start of operations but is often missed or overlooked during end-of-warranty inspections.

One solution to cable abrasion in drip loops comes from the collaboration of three companies headed by Lapp USA, a global cable manufacturer. The SOHL (from company initials) provides a range of modular clamps and sections to keep cables from rubbing against one another. One device, informally called the snowflake star clamp, serves as a multi-function, engineered cable gland, and management system for drip loop applications. The device keeps cables sufficiently separated to prevent them from wearing each other’s insulation.

You can find this article and others in the 2018 Wind Renewable Energy Guidebook available here.

Filed Under: Cables & connectors, News, O&M