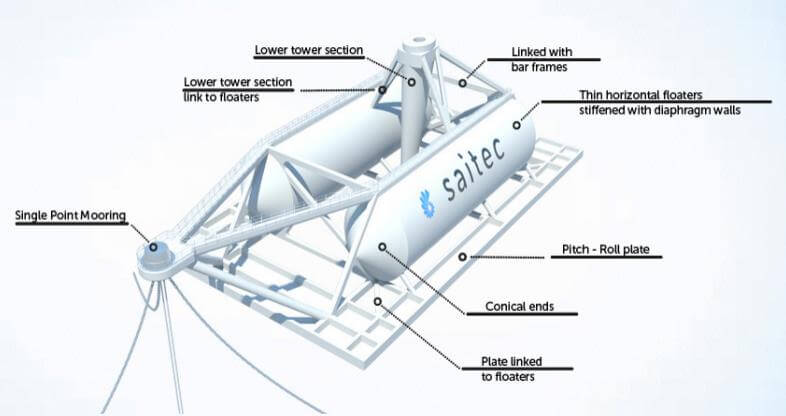

SATH is a prestressed concrete, floating wind turbine platform consisting of two cylindrical and horizontal hulls with conical ends. The hulls are linked to each other through bar frame. The hulls are also shell structures with circular or ovoidal cross section. They are internally stiffened and divided into compartments by cross bulkheads. The tower support is fixed to the floating elements through another auxiliary structure.

To increase the natural periods in pitch and roll oscillations, the floating elements are attached to flat, horizontal plates arranged submerged in the lower area of the platform. These elements are made of solid slabs lightened with a ribbed structure.

Finally, the platform is moored by a Single Point Mooring (SPM) system that lets SATH rotate around like a weathervane, helping yaw control system to maintain rotor plane facing the wind. SPM and platform ship shape allows also lower environmental loads in the mooring lines. This Single Point Mooring commonly employed in the oil and gas industry reduces the strengths suffered by the platform.

The large flat plat below the floats helps stabilize the platform. Also, only one tug is needed to tow the platform to its site.

SATH´s main advantage is the capacity to reduce the Levelised Cost of Energy (LCOE), targeting both Capital and Operational Expenditures with the smart use of concrete. SATH is even currently cost competitive to monopiles.

SAITEC Engineering Co. founded in 1988 in Leioa, Spain, presented the floating platform for offshore wind applications last month at EWEA in Paris 2015. This design has been in development for the last three years by a multidisciplinary team from SAITEC. Intensive test campaign with several scale models in the water tanks of Instituto de Hidráulica Ambiental, University of Cantabria, has demonstrated its performance in operational and extreme environmental conditions.

When talking about Renewable Energy it is all about reducing the Levelised Cost Of Energy. LCOE is composed by CApital EXpenditures and OPerational EXpenditures, Saitec’s vision is to reach this cost reduction by tackling both CAPEX and OPEX.

SATH is not just the most competitive floating solution for Offshore Wind Industry but it is a current cost competitive solution to well tested monopiles.

SATH may have a slightly higher cost regarding platform manufacturing compared to monopiles, but total CAPEX is decreased with significant installation cost reduction, due to its Plug & Play nature.

The Plug & Play installation capacity allows avoiding use of expensive vessels for big parts maintenance causing a dramatic cost reductions on operation. Another key point in the OPEX cost-reduction target is the fact that concrete has low maintenance requirements compared to steel solutions.

Filed Under: News, Offshore wind