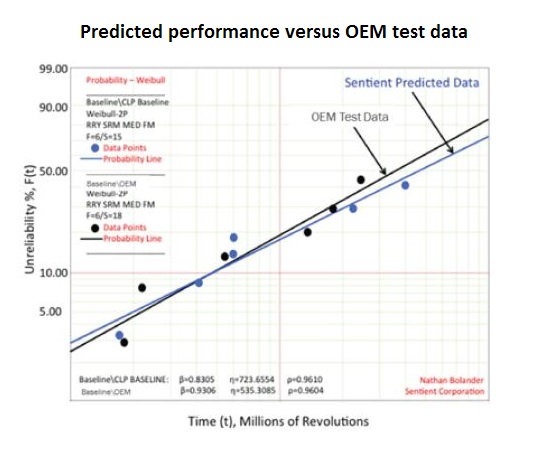

DigitalClone’s predicted bearing-fatigue data compares well to data compiled by an OEM over a long period.

Most in the wind industry are aware that the main source of premature wind turbine failures is its gearbox. As a result, wind farm operators must evaluate the asset risk of their turbines because the average cost of fixing a wind turbine is between $300,000 and $700,000 per failure. This means wind-farm operators can easily incur costs ranging to millions of dollars to deal with several gearbox failures.

Sentient Science has developed a prognostics based computational solution called DigitalClone that simulates real-world operating conditions for wind turbines. The system uses a “ground truth” model that represents a specific wind turbine and how it reacts under different operating conditions.

The system provides an accurate prediction of the performance of specific wind turbines down to their microstructure and accurately predict their its remaining useful life. This prognostics approach can be used to simulate “what if” scenarios to let wind farm operators adjust operating conditions for a required performance.

The result is the wind farm operator can focus on predicting failure instead of looking for indications of failure within data. DigitalClone runs itself so the wind farm operator can focus personnel on other tasks for greater productivity.

DigitalClone is said to evaluate all mechanical systems in a wind turbine and has the ability to study a specific parameter using a parameterized model. This parameter can be changed to see how this affects operating life and reliability.

Prognostics can predict what the future failure would looks like and take steps to help the wind farm operator extend Remaining Useful Life or RUL. Among the parameters examined by the software to extend RUL are de-rating, surface treatments, lubricant selection, the right type and timing for remanufacturing and parts from specific OEMs. The benefits of the software can lead to a substantial ROI for wind farm operators. Initial estimates indicate that savings of $150,000 per turbine per gearbox replacement can be achieved in this manner. DigitalClone will let wind farm operators more efficiently manage their facilities through the development of significant cost savings and lower overhead.

Sentient Science

www.sentientscience.com

Filed Under: News, O&M