The basket tray is good for demanding high tech and industrial applications, and represents a new standard in fast and safe installation for protecting and managing high volumes of data and power cabling.

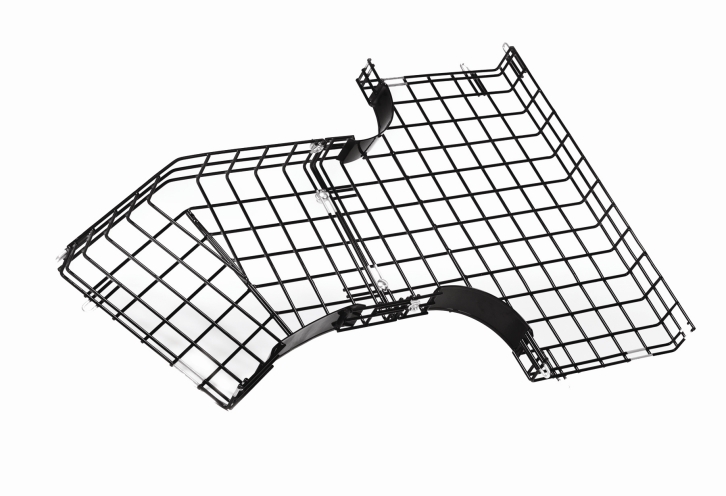

The QuickTurn Basket Tray System from Thomas & Betts offers a comprehensive selection of prefabricated basket tray fittings that help reduce installation time by eliminating the labor-intensive task of cutting fittings on the job site. In addition to standard straight sections, the QuickTurn Basket Tray System includes fittings for turns, Ts and elevation changes.

The basket-tray system also eliminates on-site fabrication, which reduces worker exposure to potentially hazardous cut wire ends. cable tray straight sections and pre-fabricated fittings also feature integrated loops that ensure proper bonding, with no secondary cables, lugs or straps required, and are available in a variety of configurations, sizes, colors and accessories.

“Eliminating the need for onsite fabrication and additional cables, lugs, and straps for bonding and grounding reduces installation time for basket tray assemblies by as much as 80%,” said Chad Smith, director, product management at Thomas & Betts. “By including a fitting for every need, the assemblies arrive at the site prefabricated, with no need for cutting in the field.”

The QuickTurn System offers additional time saving with one-tool installation. Other features include low-resistance corner plates for quick cable pulling and ensuring minimum bend radii are maintained and post-fabrication powder coating to protect welds, under even the harshest conditions. Available in five colors, as well as stainless steel, they feature easily paintable surfaces. Zinc-free components are available upon request. The basket tray is good for demanding high tech and industrial applications, and represents a new standard in fast and safe installation for protecting and managing high volumes of data and power cabling.

Thomas & Betts

www.tnb.com

Filed Under: Cables & connectors, News