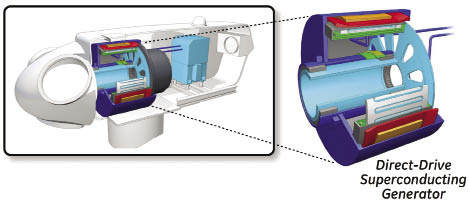

GE says its experience with superconducting equipment from its healthcare MRIs is applicable to superconducting generators for wind turbines. High torque at low rotational speeds may let wind turbines product up to 15 MW without a gearbox. See where the direct-drive superconducting generator is located in the wind turbine nacelle.

The technology development arm of a large electrical firm says it has begun work on the first phase of a two-year, $3 million wind project from the U.S. Department of Energy. GE Global Research (ge-energy.com/wind) says it will begin work on a next-generation generator for wind turbines that could support applications in the 10 to 15-MW range.

Conventional wind turbines often use a gearbox to increase slow rotor speeds to a higher rpm required by conventional generators. While such drivetrains are effective, they become expensive as they scale to larger wind platforms due to their additional weight and maintenance needs. It is possible to get additional power from larger drivetrains, only with an increase in the cost of electricity.

“New technologies will be needed to support larger-scale wind platforms,” says Keith Longtin, Wind Technology Leader, GE Global Research. He says the company will apply its experience with superconducting magnets used in healthcare MRI equipment. “Field windings are where we want to use the superconducting materials and cryogenics. So to leverage MRI experience, we will go with the topology of a rotating armature, sort of the opposite of a conventional generator.”

Longtin adds that superconducting technology may allow significant improvements to the generator and eliminate the gearbox. For example, magnetic fields would be larger from superconducting coils, even larger than those from rare-earth magnets. Hence, greater outputs from a similar size. The key is in reducing generator size and weight while dealing with lower shaft speeds and high torque. For size comparisons, Longtin says, “Our offshore turbine is rated for 4.1 MW, has a diameter of about 6 m, and weighs about 85 metric tons. We think with superconducting technology we can get 10 to 15 MW from about a 5-m diameter and the same weight. So that’s about three times the output.”

GE says the superconducting machine will use commercially available cryogenic coolers (for temperatures below 77°K) to improve the reliability of the complete machine. “We will investigate use of superconducting materials such as niobium-titanium, niobium-tin, MgB2, YBCO, and other second generation materials along with liquid nitrogen, helium, and neon to get the generator to superconducting temperatures, and techniques for staying there,” says team member Kiruba Haran, Manager of the Electric Machines Lab at GE Global Research.

The proposed superconducting machine aims to have more then twice the torque density of competing technologies and will further reduce dependence on rare-earth materials prevalent in permanent-magnet generators that are finding favor in recent turbines. The greater potential power from superconducting generators, coupled with better energy-conversion efficiency leads to more favorable economies of scale. For example, fewer towers would be needed for a given wind-farm output, which will help reduce the cost of energy produced by wind turbines.

The generator wind project will have two phases. Phase I will focus on developing a conceptual design and evaluating the economic factors associated with it. Phase II will explore potential commercialization of the technology. The Oak Ridge National Lab will be a partner on the generator wind project, helping investigate and mitigate high-risk technology challenges. Oak Ridge has facilities for more fundamental research, so they will run reliability testing on cryogenics. “It’s relatively easy to make something once and get the power needed, but can it be done in a reliable and cost effective manner over and over?” asks Haran. “We must do component tests to find the answer along with vibration and environmental tests for life data.” WPE

Filed Under: Generators, Nacelle, News