It costs millions to develop a new turbine so it makes sense to push the bounds of existing models. GE Energy has done so with the recently introduced 4.1-113 wind turbine. It says the 4.1-MW class machine brings a higher level of reliability to the offshore wind industry. The design builds on the company’s recent 4.0-MW unit (Windpower Engineering’s Turbine of the Month, July 2010), which is an upgrade of the company’s 3.5-MW direct-drive design. The company recently signed a contract to provide a 4.1-113 model and services to Göteborg Energi for installation in the Gothenburg, Sweden harbor in the second half of this year.

The 4.1-113 sports a 113-m blade that maximizes energy capture. The company says it has more than 16,000 units of all sizes installed onshore.

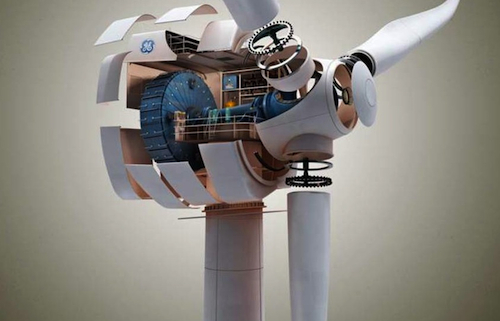

“It is the only direct-drive wind turbine designed for offshore today,” says GE VP Victor Abate. With fewer moving parts, explains Abate, the direct-drive unit provides a simple, reliable design with built-in redundancy and partial operation for major components, while focusing on keeping turbines operating reliably at sea. The direct-drive eliminates a costly gearbox which lowers operating expenses. It relies on a modular approach to maximize in-situ repair and reduce the need for large repair vessels.

The base design has been operating since 2005 on a coastal site in Norway, a harsh environment with high winds and turbulence. The company says the equivalent of 50 years of lessons learned are built into the 4.1-113. The design also draws on solutions developed for the company’s onshore fleet, including its Advanced Loads Control, sensors and algorithms that help reduce loads which are ordinarily passed to the machine and foundation.

Filed Under: Construction, Offshore wind, Projects