Synthetic lubricants have a reputation for longevity and providing good protection in a variety of equipment. To lend more credence to the reputation in wind turbine gearboxes, engineers at ExxonMobil have released their finding from more than 38,000 oil samples of Mobilgear SHC XMP 320 that go back 12 years. Researchers looked at metal content, total acid number, viscosity, and water content, all indicators of wear. The oldest sample was in service for five years.

Synthetic lubricants have a reputation for longevity and providing good protection in a variety of equipment. To lend more credence to the reputation in wind turbine gearboxes, engineers at ExxonMobil have released their finding from more than 38,000 oil samples of Mobilgear SHC XMP 320 that go back 12 years. Researchers looked at metal content, total acid number, viscosity, and water content, all indicators of wear. The oldest sample was in service for five years.

Researchers used inductively coupled plasma (ICP) spectroscopy to determine the presence and concentration of wear metals in oil. Iron, copper, chrome, aluminum, lead and tin define this category, with iron the predominant wear metal in wind turbine gearboxes.

“As the first chart shows, when ExxonMobil examined the 38,680 iron samples, it found that 99.5% possessed levels below the alert level and that over 30,000 results were under 20 ppm – or 10% of the limit,” says ExxonMobil Fuel, Lubricants & Specialties Marketing, Product Technical Advisor Rick Russo. When Russo examined oil age versus iron content in 25,680 samples, he found that iron content does not increase with the oil age, verifying the long term wear protection provided by the lubricant.

The Total Acid Number or TAN is the amount of potassium hydroxide in milligrams needed to neutralize the acid in one gram of oil. It is an important quality measurement of the lubricant because it reflects the oxidative state of the oil. Russo says that ExxonMobil examined 30,778 samples, which revealed that 99.8% of the results were below alert levels, and that 25,123 results showed little if any increase in TAN over time.

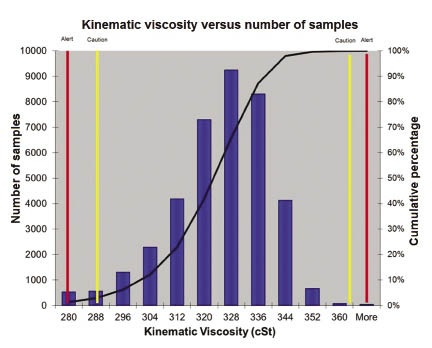

Viscosity is a measure of a fluid’s resistance to flow. The technicians examined over 38,600 data points and found that 96% of the readings, reported in Kinematic viscosity versus number of samples, were within viscosity range for the fluid.

Water as a contaminant is most relevant, because its presence may cause additive depletion, viscosity drop, and accelerated wear of components. The samples revealed low levels of water in the oil and that the levels present did not facilitate wear, suggesting the lubricant lends itself to prolonged service life.

Russo says that the review revealed several things about synthetic lubricants and Mobilgear SHC XMP 320 in particular: in the wind turbine main gearbox it provides benefits such as:

- Reduced levels of component wear and longer gearbox life

- Tendencies of the oil will increase, hence, extended lubricant life

- Retention of oil viscosity and longer gearbox and lubricant life

- Maintenance of low-level water contamination leads to longer gearbox and lubricant life.

“What does all this mean? Over the expected 20 year life of a wind turbine, the owner who increases gearbox oil life from 3 to 5 years by using Mobilgear SHC XMP 320 will save about $15,000 per turbine. In other terms, the operator of an 80 MW wind farm with 40, 2-MW turbines, will save $600,000 over the life cycle of the wind farm,” says Russo. For a more complete version of their report, see www.tinyurl.com/exxonmobil. WPE&D

Filed Under: Lubricants, News