To meet demand for wind energy in North America, Shell Lubricants is making a new portfolio of products available for its tough applications, particularly in hydraulic systems, blades, gearboxes, and yaw and pitch drives. The company provides products and services for the wind value chain, from component manufacture and turbine assembly, through transportation, construction and installation, to service.

Shell Lubricants says it recognizes the significance of reduced reliability and demands of operating wind farms in remote locations (on and off-shore) and in challenging climatic conditions. As a result, the challenge requires lubricants and greases for a long service life. To keep a wind turbine running reliably and extend component life, the company supplies a range of innovative lubricants backed by global expertise and delivered by on-the-ground technicians.

The co adds that it works closely with leading wind turbine manufacturers, component suppliers, and industry associations to understand emerging lubrication needs, the rapidly changing industry, and manufacturer specs. In addition, the company complements its products with a comprehensive oil analysis program, Shell LubeAnalyst, which can help operators monitor the condition of their lubricant and equipment, and avoid unscheduled downtime.

A few products Shell Lubricants offers to the wind industry include:

- Tellus Arctic 32. It is a hydraulic fluid for extreme-climate wind turbines, and recommended or listed by suppliers such as Svendborg Brakes, and by wind turbine OEMs including GE Wind, Voith Wind, Vestas, Dongfang Wind Turbines, Sinovel, RePower, Nordex, and DHI. The product has demonstrated its performance in the harsh winters of Mongolia, Scandinavia, and the Americas at temperatures as low as -40ºC.

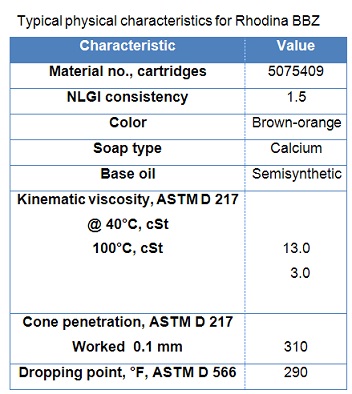

- Rhodina BBZ protects bearings against fretting corrosion, moisture contamination, and false brineling at temperatures as low as -55ºC.The massive blades of a wind turbine are adjusted using grease-lubricated blade bearings, which if insufficiently lubricated, can fail through the mechanisms mentioned. Rhodina BBZ lubricates blade bearings of many wind turbines from blade-bearing suppliers such as Rollix, Rothe Erde, IMO, Rotek, and Liebherr.

- Omala HD 320 synthetic gear oil provides excellent protection against common failure modes, including micropitting and bearing wear. Gearbox reliability is critical for wind turbine reliability. Omala HD 320 provides excellent low-temperature fluidity and long oil life along with benefits for difficult to maintain wind turbine gearboxes.

In addition, the company also offers Shell Tivela S 150 & 320 synthetic gear oil for yaw and pitch drives; Shell Albida EMS 2 electric motor bearing synthetic grease; Shell Stamina HDS main bearing grease; and Shell Malleus GL & OGH premium quality open gear grease.

Shell Lubricants works with turbine manufacturers and their component suppliers to deliver best performance from its lubricants. The lubricants are approved by or meet the specifications of many equipment manufacturers, including Bonfiglioli, Bosch Rexroth, Brevini, Dongfang, Acciona, Sinovel, Gamesa, GE Energy, Hansen, IMO, Jahnel & Kestermann, Liebherr, Lincoln, Rollix, Rothe Erde, Siemens Wind Power, SKF, Svendborg, Vestas Wind Systems, and Winergy

Shell Lubricants

Filed Under: Bearings, Lubricants