Editor’s note: Natural gas fired plants such as the one described below are ideal partners for the growing wind-power industry because the gas plants can cycle up and down in response to the demand for power, and in minutes. Conventional power plants such as those powered by nuclear energy or coal run best at steady state.

Clean Energy Future has chosen Siemens as the turnkey supplier for Lordstown Energy Center – a new 940 MW natural gas-fired combined cycle power plant (CCPP) to be built in Lordstown, Ohio. The facility will be a Siemens 2×1 SCC6-8000H Flex-Plant combined cycle power plant, featuring the Siemens record-breaking H-class technology in a facility designed for fast, flexible operation to support renewable integration. Siemens Financial Services co-funded the development loan and will provide a pivotal 27% equity investment alongside Macquarie Infrastructure and Real Assets to help realize the project.

“Lordstown Energy Center is a very high quality energy infrastructure project with which we are proud to be associated”

Slated for operation in summer 2018, the Lordstown Energy Center (LEC) will be capable of supplying power for approximately 800,000 homes in the PJM Interconnection regional transmission organization. In addition, Siemens has signed a long-term service agreement to help ensure the reliability, availability and operational performance of the units. The service will include Siemens advanced remote monitoring and diagnostics, part of the Siemens Digital Services portfolio.

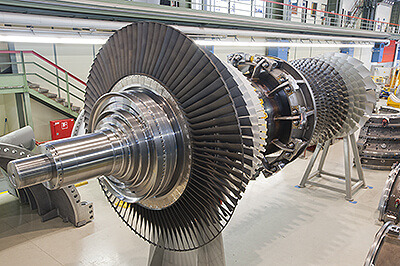

Siemens Flex-Plant combined cycles are designed to minimize environmental impact and maximize operational flexibility to reduce greenhouse gas generation and support renewable integration. The turnkey solution for Lordstown will include two SGT6-8000H gas turbines, one SST-5000 steam turbine, two SGen-1200A generators as part of the gas turbine packages, one SGen-2000H generator as part of the steam turbine package, and a Siemens SPPA-T3000 integrated plant control system. The plant design includes Siemens industry leading Flex-Plant combined cycle features, including the fast gas turbine start which reduces start up emissions up to 95% and Siemens Clean-Ramp technology to maintain low emissions while load following. The gas turbines and steam turbine will be manufactured at Siemens’ Charlotte Energy Hub, which is the main production facility for Siemens’ 60 Hz power generation. The project also includes NEM DrumPlus heat recovery steam generators, as well as full balance of plant scope.

“As we look at the future of power generation in the United States, projects like the Lordstown Energy Center provide an example of how communities can harness cleaner-burning and affordable natural gas to provide efficient and reliable power,” said John Gibson, Senior Vice President, Head of Sales North America at Siemens Power and Gas Division. “We are pleased to be the technology partner for Clean Energy Future, providing a turnkey solution of world-class power equipment, including gas and steam turbines manufactured by Siemens workers at our U.S.-based energy hub in North Carolina. This equipment will be serviced with pride by Siemens for many years to come.”

“Lordstown Energy Center is a very high quality energy infrastructure project with which we are proud to be associated,” said Chris Leslie, Chief Executive Officer of Macquarie Infrastructure Partners III (MIP III). “LEC is expected to utilize the latest in high efficiency gas turbine power generation technology – technology that is both cost effective and more environmentally friendly than the aging coal-fired capacity that it will replace.”

“The support we were able to provide to this project is a great working example of how Siemens can act as a full-service partner to our customers,” commented Kirk Edelman, CEO of Energy Finance, Siemens Financial Services. “Leveraging our financial services capabilities alongside our power generation solutions, Siemens funded the development loan as well as an equity investment in Lordstown, underscoring our commitment to the long-term success of this project.”

For more: www.siemens.com/about/en/businesses/power-and-gas.htm

For further information on Siemens gas turbines, steam turbines and generators, see www.energy.siemens.com/hq/en/fossil-power-generation/

For further information on Division Financial Services, please see www.siemens.com/finance

Filed Under: News