G.J. Bertini, Novinium, Inc., Kent, Wash.

This paper reviews six neutral corrosion issues and provides data to shed some light on the overall significance of the phenomenon. The paper draws upon IEEE 1617 (IEEE Guide for the Detection, Mitigation, and Control of Concentric Neutral Corrosion in Medium Voltage Underground Cables) [1] and encompasses and expands upon the 1617 scope.

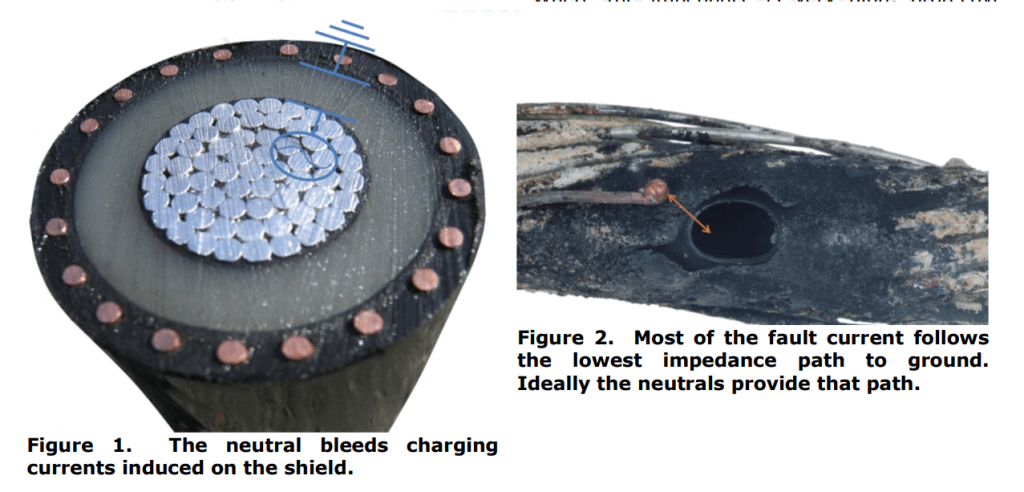

This paper defines the purposes of the neutral, the consequences of excessive corrosion, the causes and chemical dynamics of neutral corrosion, dimensions the severity of the issue in North America, describes how to detect neutral corrosion, and provides options to address neutral corrosion once discovered. The paper also suggests areas for future work to provide guidance to circuit owners on the likelihood of neutral corrosion issues in their service territories. Figure 1.

The neutral bleeds charging currents induced on the shield. The neutral has four primary purposes.

The first purpose (IEEE 1617 4.1) is to bleed currents induced onto the cable shielding. This concept is illustrated in Figure 1. The cable is not a particularly good capacitor as the distance between the two electrodes is large and the dielectric constant of the insulation is quite low – about 2.3 for PE cables. Very little neutral conductor is required to bleed these small charging currents.

The second purpose (IEEE 1617 4.2) is to provide a low impedance path for fault currents. This fault current path is particularly important for protective devices such as fuses and circuit breakers to operate as quickly as possible. Figure 2 shows a cable fault. The melted copper illustrates the high current that jumped from the conductor to the neutral. If the neutral is corroded, the fault current will find alternate paths including the soil and other nearby utilities.

Where the impedance is very high, protective tripping might be delayed. The third purpose (IEEE 1617 4.4 – Note that we will circle back to 4.3 shortly.) is to provide a system neutral for return current. Except for well balanced three-phase loads, the return current can approach the conductor current.

Underground cables with neutral corrosion

The fourth purpose of the neutral is to mitigate the consequences of a failure to successfully accomplish purposes 4.1, 4.2, and 4.4. A properly functioning neutral all but eliminates step potential and touch potential. Step potential, illustrated in Figure 4, is a difference in voltage between two feet – human or animal. Human step potential is quite low because our footsteps are close together. Potential unpleasantness is usually mitigated by shoes with nominal dielectric properties. Larger animals such as cows or horses have a greater distance between their feet and don’t wear shoes.

The charging current is too small to create any meaningful step potential, so return current and fault current are the primary causes of step potential. An ellipsoid of non-detectable or very close to zero potential will form around the damaged neutrals anchored at both vertices by a well-functioning neutral. If the distance between the two well-functioning electrodes is great enough and the soil electrical conductivity is low, the ellipsoid may intersect the surface as depicted in Figure 4. As will be shown later in this paper, the length of corrosion sites is usually limited to less than about a meter. Consequently, the probability that human or animal-detectable voltage gradients exist at the surface is quite low. That is not to say that sensitive instruments cannot detect step potential, but rather that the potential is low enough not to evoke undue concern.

For the rest of the article: www.tdworld.com

Filed Under: Cables & connectors