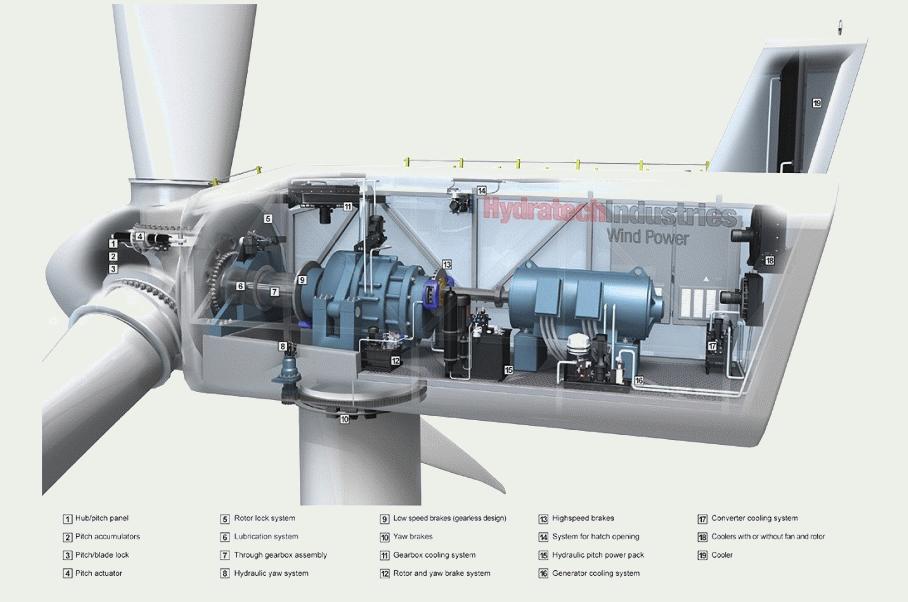

Hydratech Industries, a seal manufacturer for wind power facilities and hydraulic systems, now uses a polyurethane seal from Freudenberg-NOK Sealing Technologies for its new hydraulic accumulator. Test comparisons with other products have shown that Freudenberg-NOK’s SIMKO 300 seal ring offers distinct advantages over frequently used polytetrafluorethylene (PTFE) seals with regard to operating life, form stability and sealing characteristics.

The durability of sealing rings in piston accumulators is crucial for their operating life. For this reason, piston accumulators undergo accelerated load tests at the Hydratech test center in Sikeborg, Denmark that simulate 20 years of service life. During the tests, engineers measured the behavior of the seals under pressures greater than 200 bar and temperatures from -104 to 140°F, conditions that exceed actual stresses.

Based on its form stability, extreme hardness, and low abrasion, Hydratech now uses the SIMKO 300 from Freudenberg-NOK. The seal “fully meets our expectations and is impressive due to its long service life,” said Jimmi Wenderby, Hydratech research and development manager.

Most sealing systems in piston accumulators work with two seals, one for oil and another for gas. This leads to increased wear due to the extreme load, especially in PTFE seals. By contrast, the SIMKO 300 is a single seal (consisting of a seal ring and a pressure ring) and is made of polyurethane. Polyurethane’s hardness grade of 98 Shore A corresponds to that of PTFE but is much more robust. Its susceptibility to potential surface damage during installation is also lower. The pressure ring creating the necessary pre-tension is made of an elastomer.

The SIMKO 300 seal’s high form stability, its surface firmness, and its long operating life make it especially appealing for use in hydraulic pitch controllers in wind power facilities. They are an important component of the security in wind power facilities, as the piston accumulator must not merely function reliably under extreme weather conditions but also withstand the high differential pressures that are also produced. The accumulator must be able to operate leak-free over very long periods of time.

Freudenberg-NOK Sealing Technologies

www.fnst.com

Filed Under: Components, Hydraulics, News, Seals & slip rings