Michelle Froese | Senior editor

Windpower Engineering & Development

MAINTSYS and SIMSTALL are two design and maintenance tools built on Shorelines’ advanced Shoresim simulation platform, which simulate the sequence of offshore project development and O&M to determine the best course of action at each stage of a project’s lifecycle. SIMSTALL simulates a full scope of offshore project construction, including port operations, logistics, installation, commissioning, and testing. MAINTSYS analyzes operations and maintenance, and marine logistics for offshore wind farms.

The days of trial and error are largely behind us. Modeling and simulation software has made investments in new wind projects far less risky. Advances in such software improves the confidence of OEMs, wind developers, financiers, and operators because they can simulate and then analyze the entire lifecycle of a proposed wind farm from its early stages of project planning through O&M and all the way to decommissioning.

Simulation software lets engineering, construction, and operations teams explore turbine design trade-offs, simulate siting strategies, mitigate environmental and construction risks, predict component maintenance, and — perhaps most importantly — estimate production and the return on investment (ROI). In the offshore wind sector, this capability is critical to project success. Offshore wind costs have dropped, but in the U.S. they are still about twice that of onshore projects.

“Offshore wind costs are higher than onshore and the projects pose greater risks to developers, construction crews, and maintenance teams because of marine conditions and logistical challenges,” says Michael Bjerrum CCO and Partner of Shoreline AS. Norwegian-based Shoreline provides verified and proven cloud-based simulation software and consulting for the offshore wind industry. “However, it is now possible to not only evaluate how a certain turbine model may measure up over time offshore but also assess different logistics scenarios prior to the start of construction. Simulation software can reduce offshore risks and project costs significantly.”

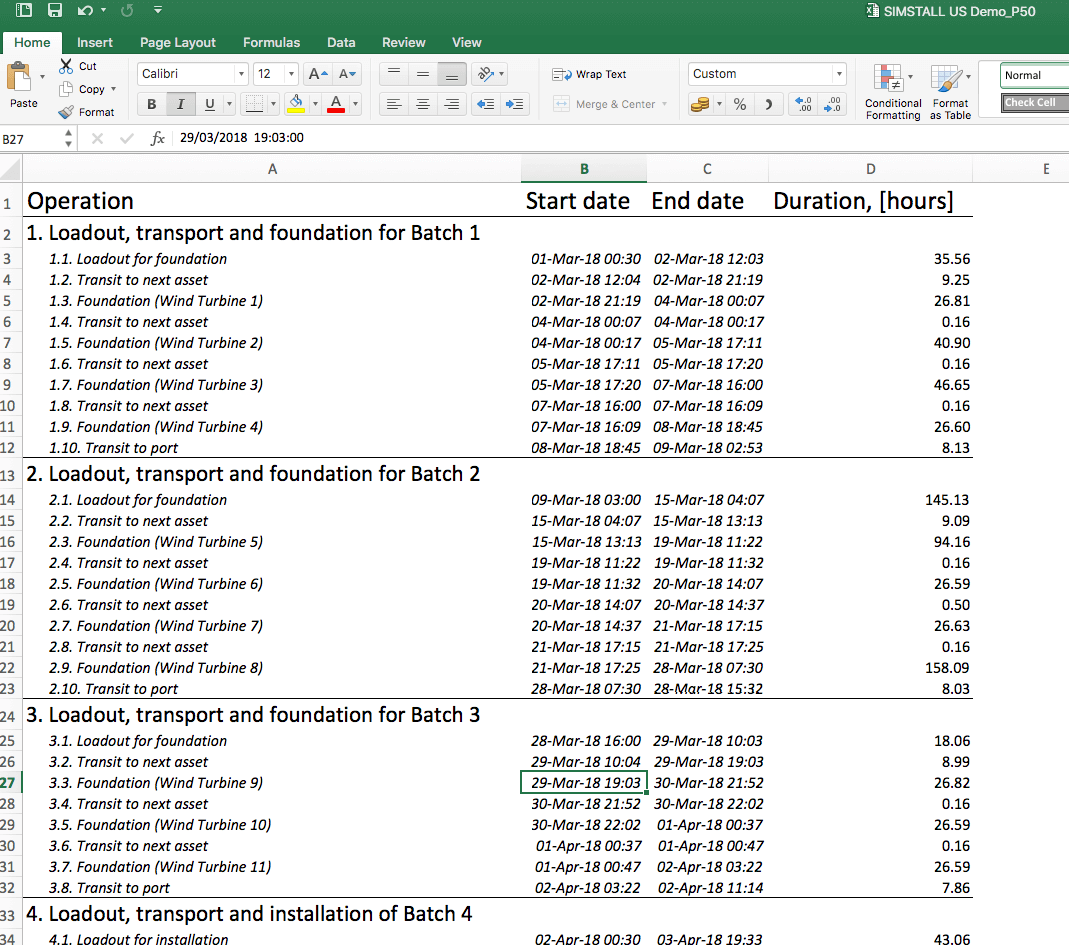

Logistics can also have considerable impact on the profitability of a wind farm, with a share of up to 20% of total project costs. By first simulating different scenarios, however, it is possible to compare alternative ports, vessels, maritime logistics, and to identify potential safety concerns, bottlenecks, and delays.

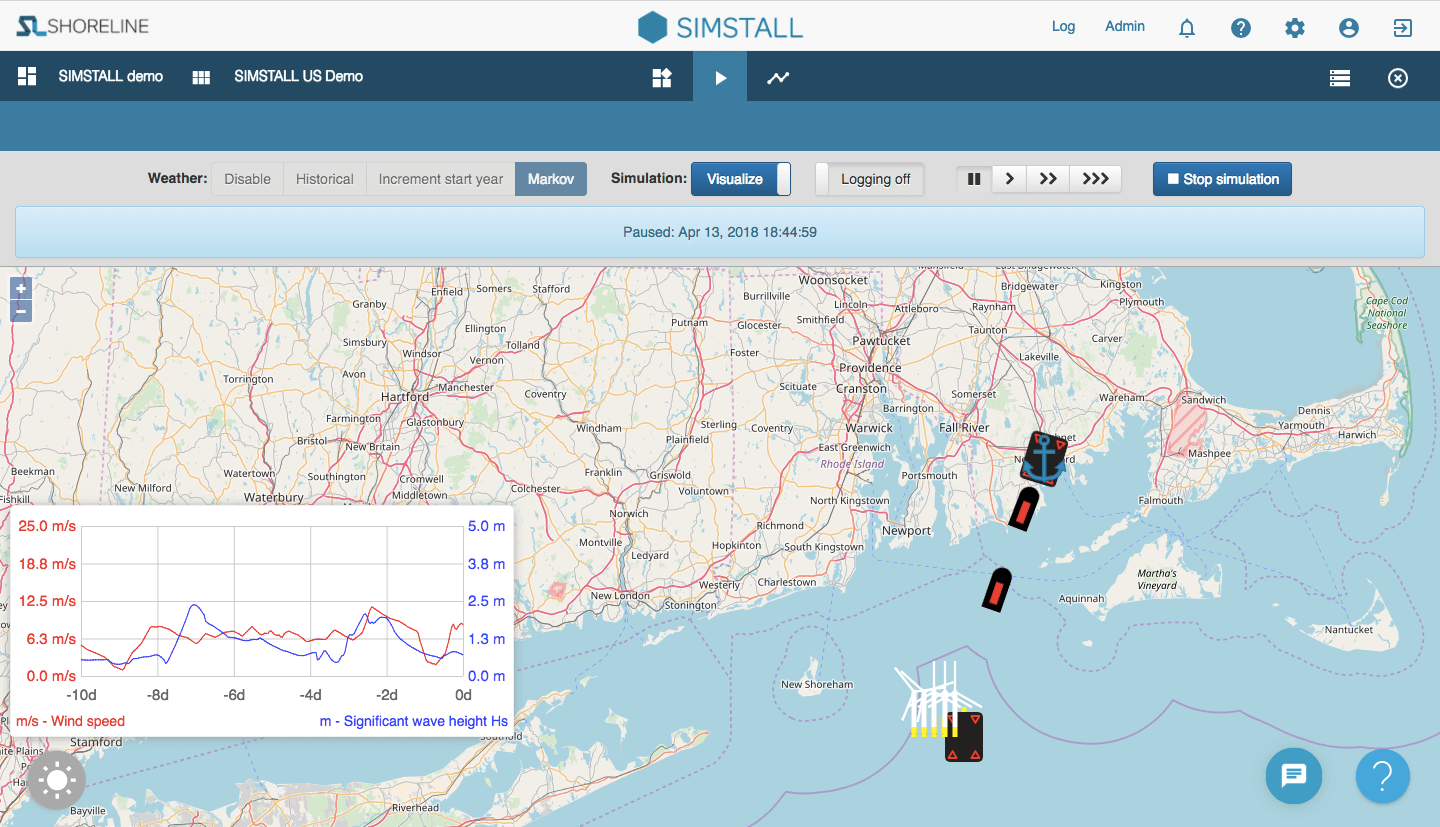

“For example, our simulation engine Shoresim can model all types of vessels, helicopters, technicians and wind turbines on an individual level, defining attributes and movements object by object,” he says.

To ease the building of a virtual wind farm, Shoreline’s SIMSTALL simulation software maintains a comprehensive input library of vessels, helicopters, ports, and wind-farm assets, all based on publicly available data. The software can simulate the full scope of offshore wind farm construction, including port operations, logistics, installation, commissioning, and testing.

It makes sense to model a transport vessel’s capability and route, or a turbine’s projected power output (Shoreline Simulation includes a detailed vessel and turbine database). Bjerrum points out that a crane simulation may be just as important, and particularly as a safety precaution.

“Just imagine: before ever visiting a site to do his or her job, a crane driver can now track and physically model the site and his or her anticipated movements onsite. The simulation provides a virtual heads’ up and practice before doing the job — thereby reducing risk.” He adds there are even simulation models of the transition pieces that make up a turbine tower, so a wind tech can practice how to access that turbine prior to actual construction or maintenance offshore.

“We model each and every element of a project, including the turbines, foundations, vessels, ports, technicians — yes, even each person is assessed.” Bjerrum says this is important to determine how many technicians and vessels will be required for each offshore activity, and the cost. A user can produce a detailed model that includes the patterns and skills of each technician. “It is possible to run many potential scenarios, or what we call ’sensitivities,’ to determine the best course of action for a project.”

One such sensitivity could be something as seemingly random as he project start date. “You may be surprised how production output may vary based on the start date when inputs for historical weather data are considered in the simulation,” he says. Weather is one of the most crucial variables in construction of an offshore wind farm.

“It is also possible to input limitations — so not just what each asset or component can do but what they cannot do. For a vessel or helicopter, this can include restrictions related to wave height, wind speed, visibility, daylight, and others,” he says.

Modeling can assist answering typical questions such as, “What turbines should I choose?” or “How much downtime should I anticipate due to weather?”

Shoreline offers a Markov chain model (a sequence of possible events, the probability of which are based on past events) for generating synthetic weather time series that’s based on historical data. The model captures the uncertainty inherent in weather data, which may affect an offshore wind project’s timeline.

Shoreline’s simulations can also examine what types of agreements are ideal. “In this case, a user can consider different scenarios and which contract strategy may make the most sense from a cost and risk perspective,” says Bjerrum. “For instance, is it better to go with one main wind-turbine supply agreement combined with an EPCI contract for the remaining balance of plant, or multiple agreements with different companies to try and cut costs?” An EPCI is an engineering, procurement, construction and installation agreement. “Each decision impacts a project’s bottom line, and can be first audited using simulations.”

Where do these simulations come from? “We’re not starting from scratch,” he says. “We have incorporated many years of European offshore wind industry experience in our simulation tools, and we continually upgrade data as it’s made publically available.”

Essentially, simulation software is a data-transfer tool that lets users experiment with different available assets and scenarios to find one ideal for their project. “A digital platform is a fairly cost-effective and risk-free way to transfer information and experience from the marketplace to an interested user so that his or her experience will be as successful as possible,” says Bjerrum.

Filed Under: News, Offshore wind, Projects, Software