SKF custom machined seals for the wind industry exhibit high form stability, can be developed in a wide range of sizes and dimensions, and can be configured either in solid or split designs.

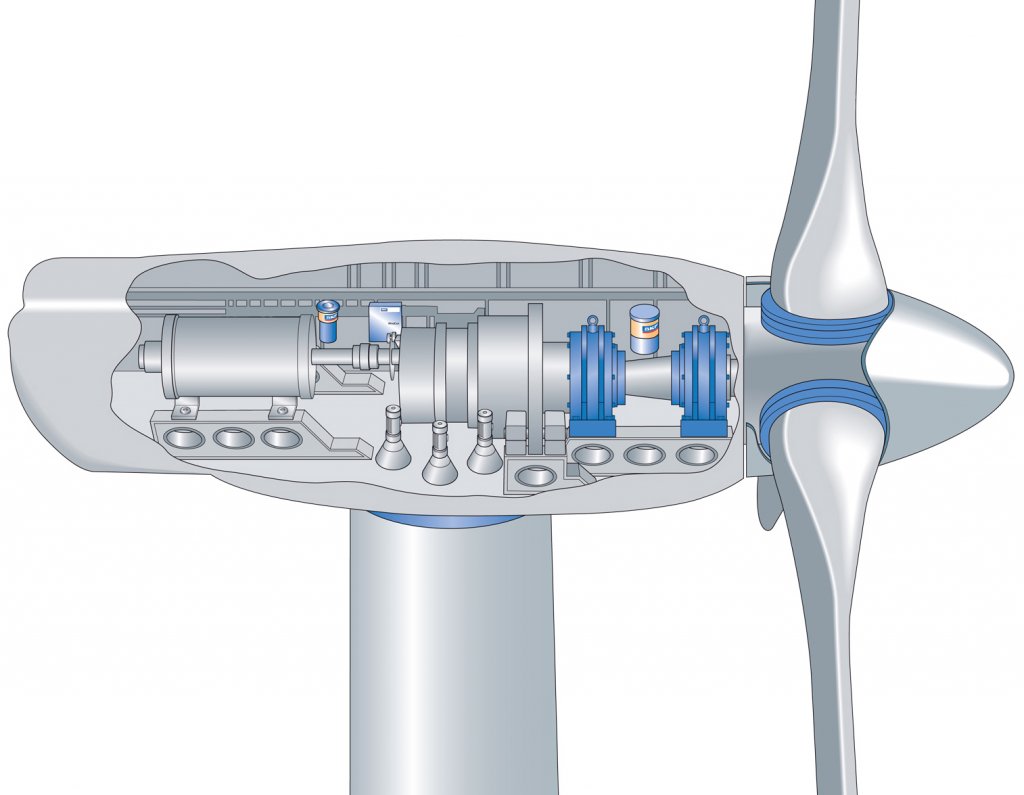

SKF introduces the capability to manufacture custom machined seals for all wind turbine applications, whether to meet OEM specifications or to fix or upgrade existing sealing systems. A variety of proven seal designs and sizes, proprietary high-performance materials, and flexible manufacturing processes combine to deliver robust wind turbine sealing solutions tailored and delivered in short order. SKF custom machined seals are ideally engineered to facilitate up-tower installation, optimize protection against the ingress of contaminants, promote retention of lubricant, and ultimately help boost turbine reliability, productivity, and energy efficiency. Seals can be custom machined for main shafts, gearboxes, rotor bearings, yaw drives, pitch drives, and rotor brakes, among other critical applications.

SKF custom machined sealing solutions for the wind industry include:

- Rubber reinforced radial shaft seals made from hydrogenated nitrile rubber (HNBR) or machined from a proprietary polyurethane compound;

- Advanced polyurethane compound excluder seals exhibiting excellent abrasion resistance and tear strength

- V-ring seals (NBR, HNBR or polyurethane)

- SKF Speedi-Sleeve to replace damaged shaft surfaces without requiring power tools, heating, or changes in seal sizes, and

- Hydraulic seals compatible with hydraulic fluids to meet the high power density demands of pitch and yaw drives and hydraulic brakes.

SKF custom machined seals for the wind industry exhibit high form stability, can be developed in a wide range of sizes and dimensions, and can be configured either in solid or split designs (for easier handling and installation).

SKF USA Inc.

www.skfusa.com

Filed Under: News, O&M, Seals & slip rings