Design firms run on engineering and support software. One recent announcement reported on an OEM and engineering software firm teaming up to develop what might be called TurbineCAD. The final product has not been announced.

Programs worth noting (and available) to the wind industry simulate the myriad of conditions a wind farm is likely to encounter, so wind plant designers and wind-site assessors can test a thousand arrangements to find a best one. For OEMs and components manufacturers, at least three different programs are of interest: composite design, stress analysis, and structural-optimization software.

In the design of turbine blades, for example, conflicting design goals confound the task of making blades longer as well as lighter. Some design software can assist with placing plies and resins for a particular strength value, but provide little guidance with weight control.

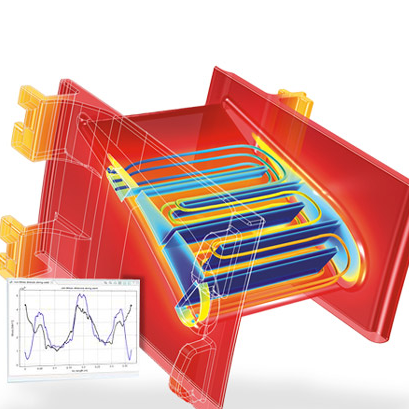

Software such as finite-element analysis can examine a design, and using wind loads supplied by a user, tell where stresses are highest and whether or not they are allowable. Optimization software can then look at several competing goals, such as low weight and long length, and adjust other characteristics defined by the user to find a best possible balance.

Blade-optimizing software begins where traditional FEA ends. Starting with a finite-element model and working with FEA solvers, the software verifies structural integrity, predicts failure modes for aeroelastic load cases, and identifies failure locations and loads. To resolve unacceptable safety factors, or simply to find a lighter weight design, it sizes (optimizes) a design by surveying many design-candidate dimensions and laminates, making allowable adjustments, to the type of internal stiffeners, for example.

Other programs worth noting include one that provides Weibull analysis. The program uses failure stats to predict the reliability of a part, mechanism, or complete machine. Lastly, a program helps design a better replacement gear. The analysis capability in the program assists in determining how a gear failed and what in a new design can avoid a repeat performance.

Filed Under: Software